Electric infusion beverage makers

A technology for making machines and beverages, applied in beverage preparation devices, kitchen utensils, household utensils, etc., which can solve problems such as damage to taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

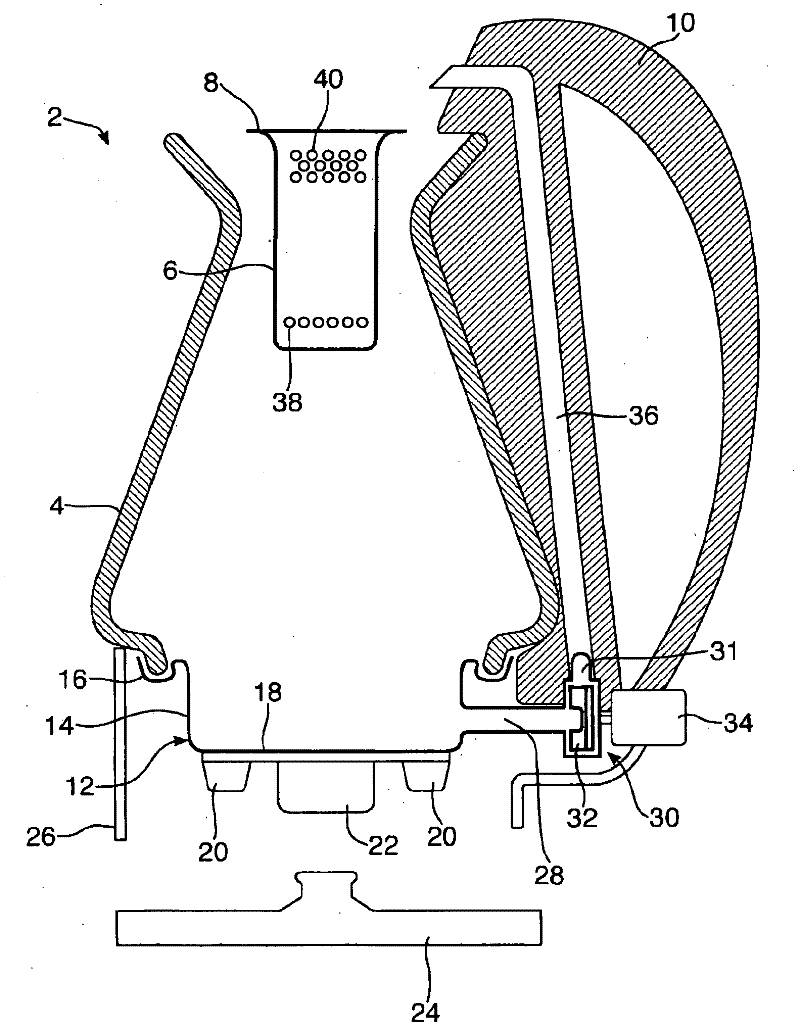

[0078] refer to figure 1 , the tea making appliance 2 comprises a water heating chamber 4 and an infusion chamber 6 installed in its top opening. The water heating chamber 4 is preferably made of a transparent or translucent material such as glass. The soaking chamber 6 is made of metal and / or heat-resistant plastic mesh. The infusion chamber 6 is provided with a lip 8 surrounding its upper edge to allow it to sit within the neck of the heating chamber 4 .

[0079] The water heating chamber 4 is provided with a handle 10 to facilitate pouring beverages therefrom. The body of the chamber 4 is also formed with a pouring lip or spout.

[0080] The water heating chamber 4 has a heating base 12 mounted to close an opening in the base of the liquid heating chamber 4 . The heating base 12 is an underboard heater comprising the applicant's standard-form Sure Seal stainless steel base plate 14, as described in more detail in WO 96 / 18331, the base plate 14 being circular and A peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com