Conduction type charging connector for electric vehicle

A technology of electric vehicles and connectors, applied in the direction of circuits, connections, contact parts, etc., can solve the problems of inconvenient use, inconsistent structure of the vehicle end and charger end, and inability to realize direct docking, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

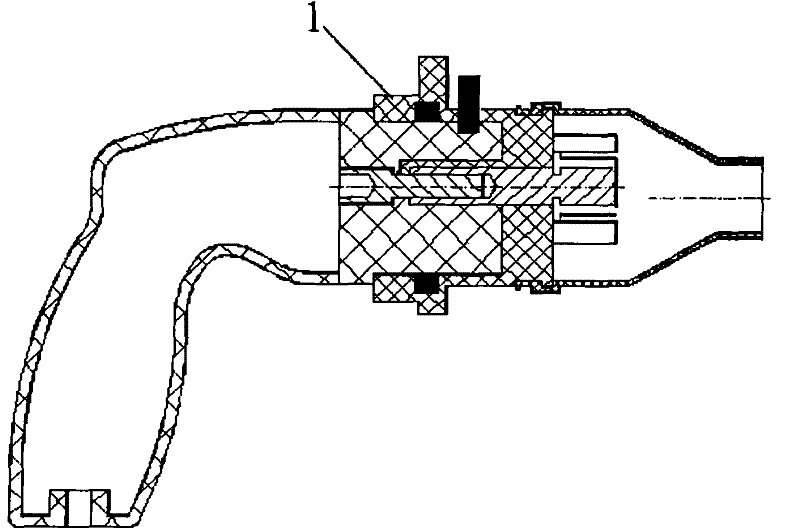

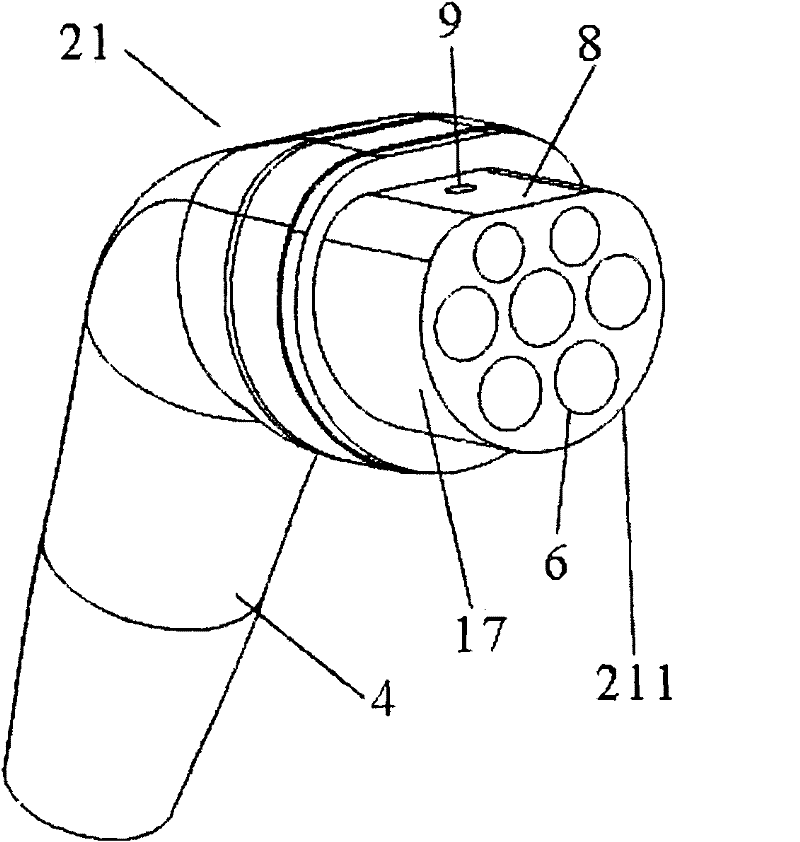

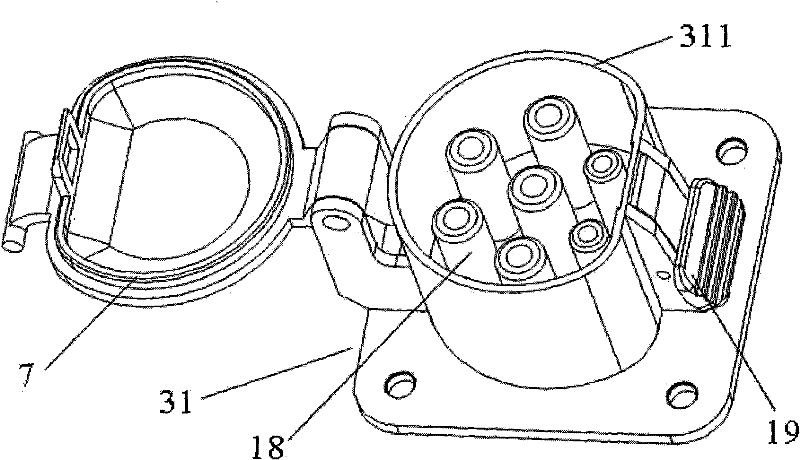

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, this electric vehicle conductive charging connector 1 of the present invention, in this embodiment, the electric vehicle conductive charging connector 1 is used for the on-board charging mode of three-phase alternating current, such as figure 1 As shown, the wires in the charging connector are not shown in the figure, and its interface structure is highlighted. The charging connector can be designed in a handle shape, which is easy to hold during use. It includes the vehicle end connection part 31 and the charger end. The connection part 21 and the vehicle end connection part 31 are arranged on the vehicle and are electrically connected to the charging system of the vehicle. The charger end connection part 21 is electrically connected to the charging power source. The charging power source is usually a charger. The end con...

Embodiment 2

[0041] Such as Figure 5 , Figure 6 and Figure 7 , Figure 9 , Figure 10 , Figure 12 , Figure 13 and Figure 14 As shown, the electric vehicle conductive charging connector of this embodiment is used for the on-board charging mode of single-phase alternating current, and it includes a vehicle end connection part 32 and a charger end connection part 22, and the vehicle end connection part 32 is arranged on the vehicle And be electrically connected with the charging device of the vehicle, the charger end connection part 22 is electrically connected with the charging power supply, the vehicle end connection part 32 includes an insulating socket 321 structure, and the charger end connection part 22 includes an insulating plug 221 structure, this embodiment and implementation The difference of Example 1 is that a grounding electrode 51, two power supply electrodes 53 and two charging control electrodes 52 are arranged in the plug 221, and the specific positional relation...

Embodiment 3

[0044] Such as Figure 8 As shown, this embodiment is an improvement on the socket in the socket in Embodiment 1 and Embodiment 2. Specifically, the locking sleeve on the outer periphery of the socket 10 is replaced by a radially telescopic spring 12, and the radially telescopic spring The combination of 12 and the elastic cantilever of the socket realizes the "soft structure" contact. The radially stretchable spring 12 is elastic, and the "pre-deformation" generated in the elastic wall of the socket can generate contact pressure in the radial direction of the socket, thereby realizing Contact compression on the circumferential surface of the post. In the process of joining the post and the socket, a larger contact pressure is realized, the contact resistance is reduced, the characteristic impedance is continuous and uniform, and the intermodulation performance and the plug-in cycle are improved.

[0045] Of course, the present invention can also have other modifications besi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com