Engineering operation control knob

A technology for controlling knobs and operations, applied to control components, mechanical control devices, control/adjustment systems, etc., can solve problems such as poor anti-vibration performance, difficult to control accurately, and lack of correlation, etc., to achieve enhanced anti-vibration performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

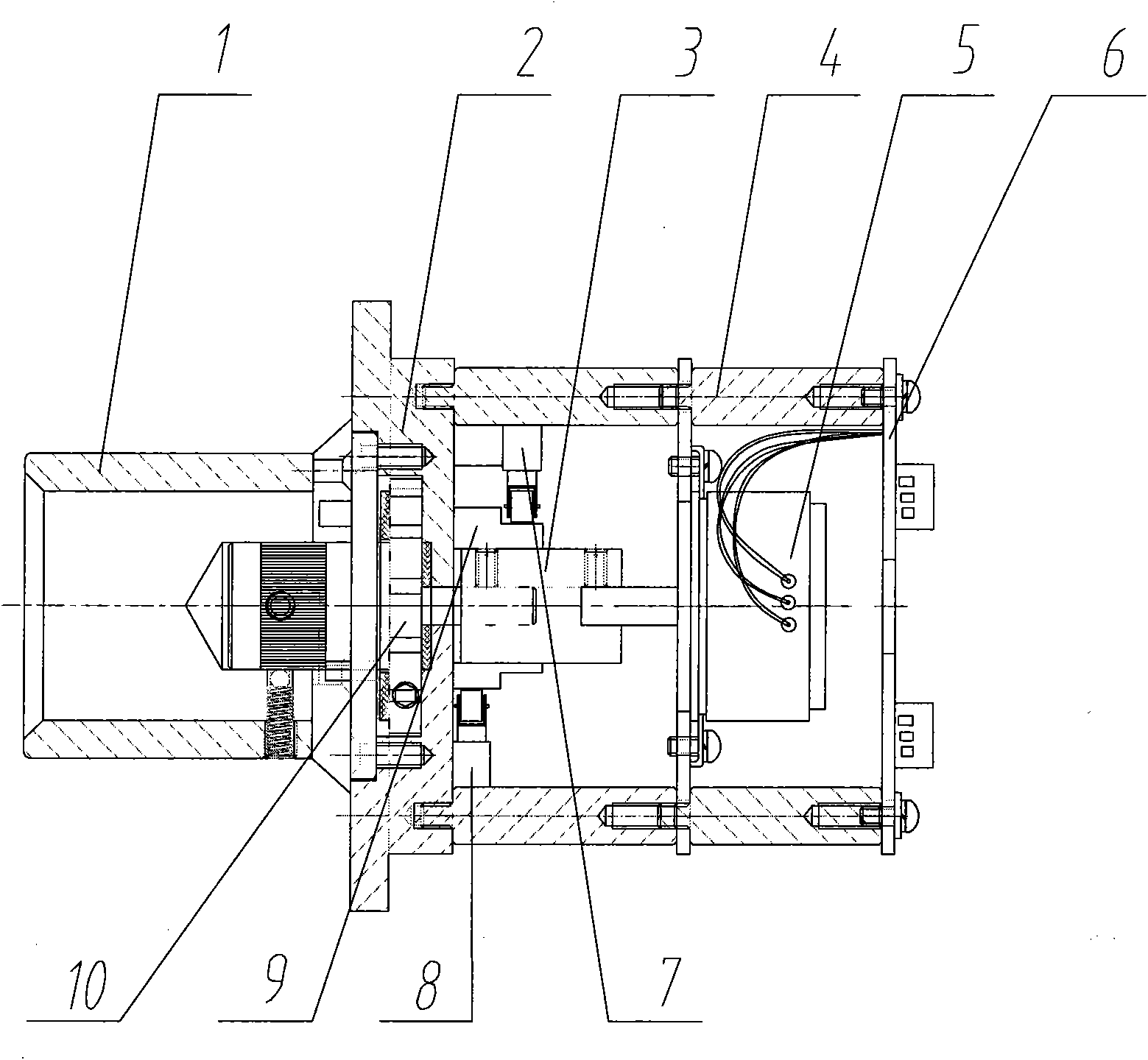

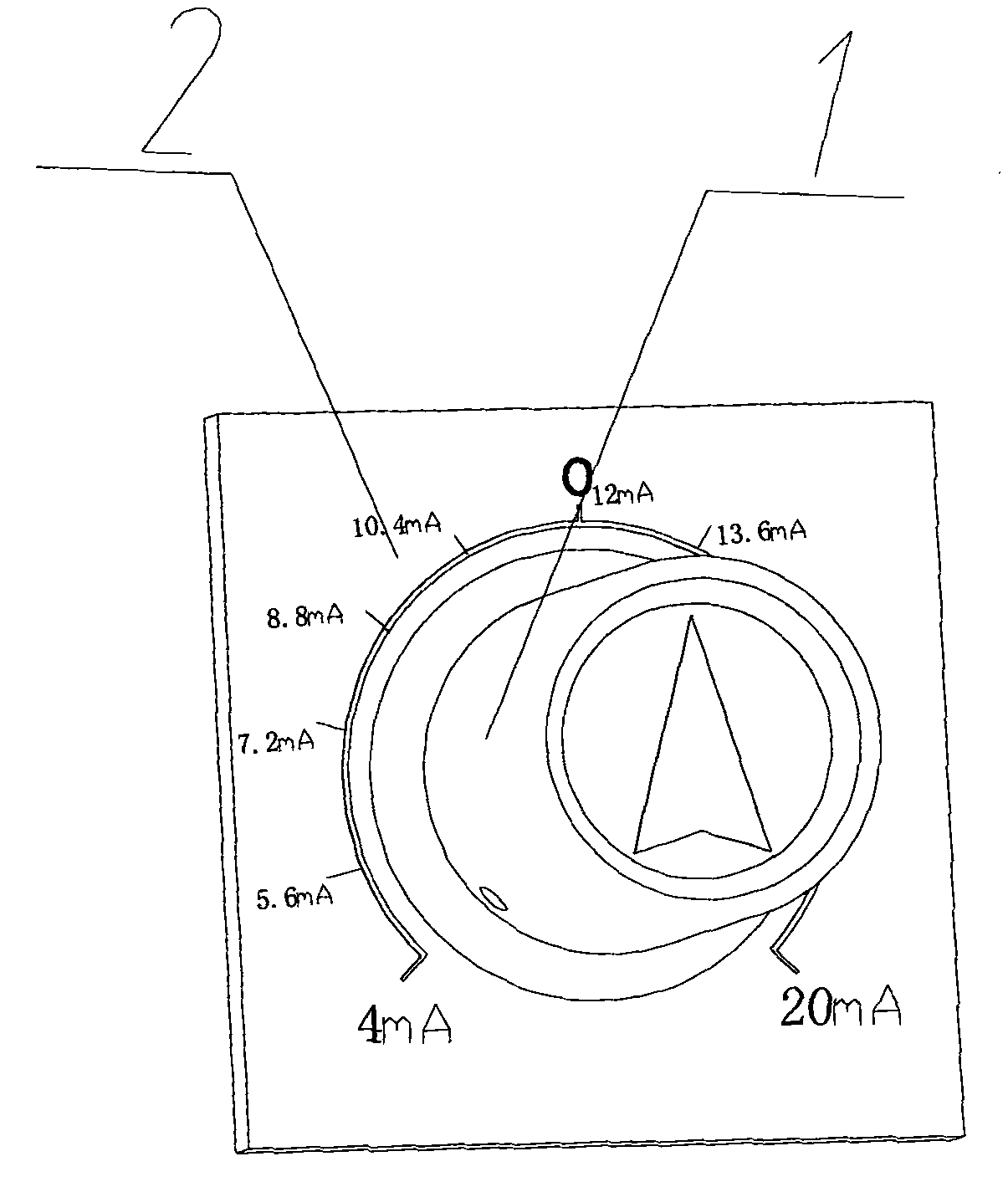

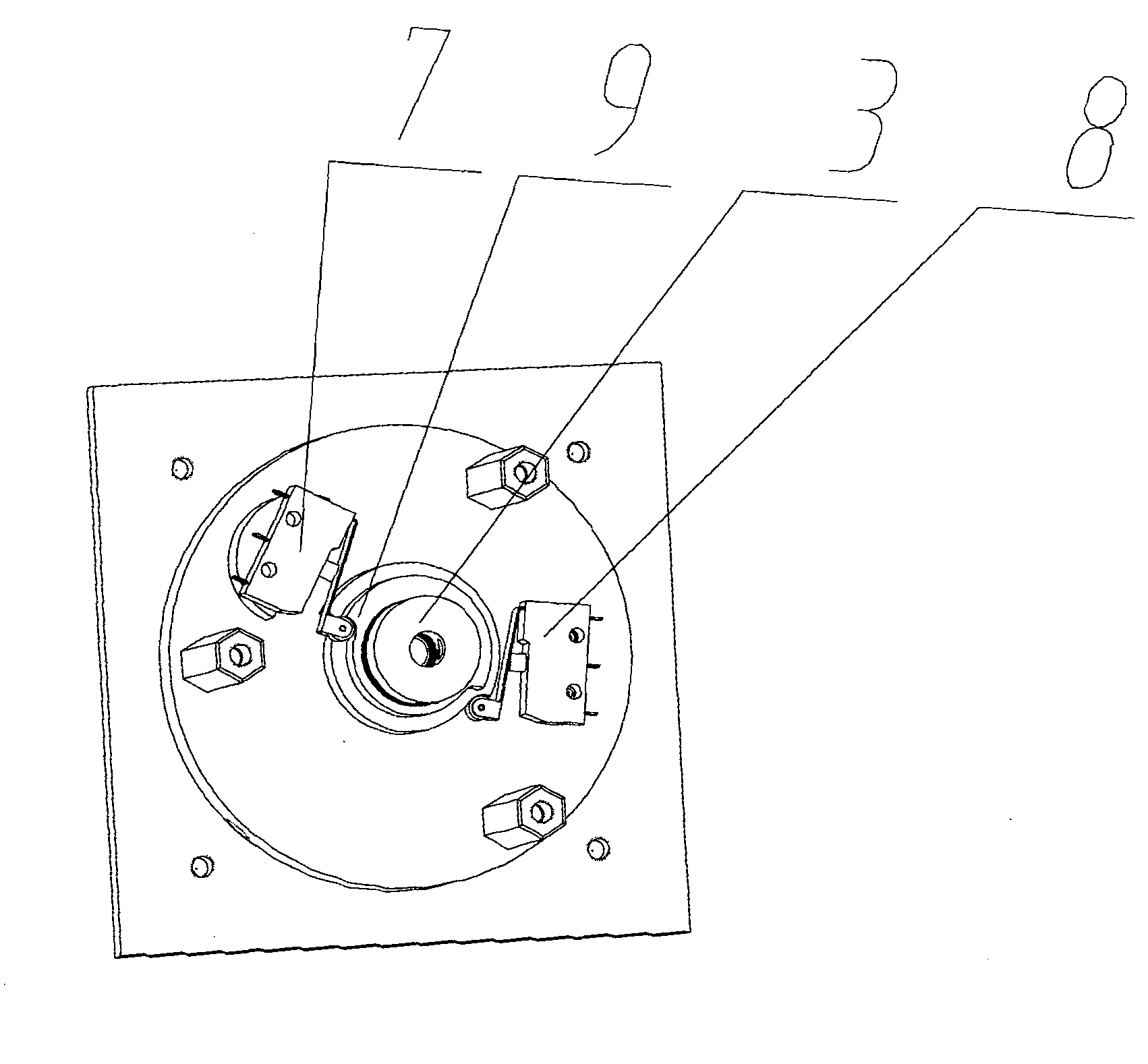

[0019] Such as figure 1 As shown in the sectional view of the engineering operation control knob, the engineering operation control knob is mainly composed of an operating handle (1), a knob seat (2), a flexible connector (3), a hexagonal copper column (4), a potentiometer (5), a circuit board (6), an upper micro switch (7), a lower micro switch (8), a concave-convex double-layer fixed transfer copper block (9), and a tooth-shaped positioning ring (10).

[0020] Among them: the operating handle (1), the parts are mainly composed of a plastic material outer ring, a rotating shaft, and a connecting screw. The diameter of the plastic material outer ring is 42mm, and the straight knurled straight-line concave-convex surface design of 0.8mm has a good grip for adults and is easy to operate accurately. Control operation; knob seat (2), the parts are mainly composed of a k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com