Testing device and testing equipment

A testing device and testing machine technology, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of spending a lot of time replacing the testing device and affecting the testing progress, and achieve the effect of saving the time of replacing the testing device and accelerating the testing progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical means and effects used by the present invention to achieve the purpose will be described below with reference to the attached drawings, and the embodiments listed in the following drawings are only for auxiliary explanation, so as to facilitate the understanding of the review committee, but the technical means of this case are not Not limited to the listed drawings.

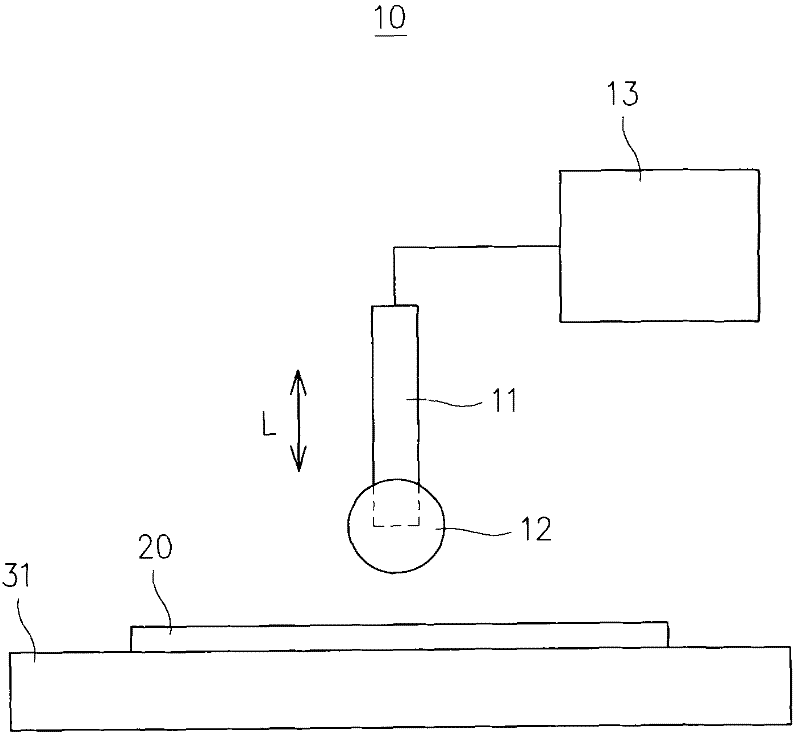

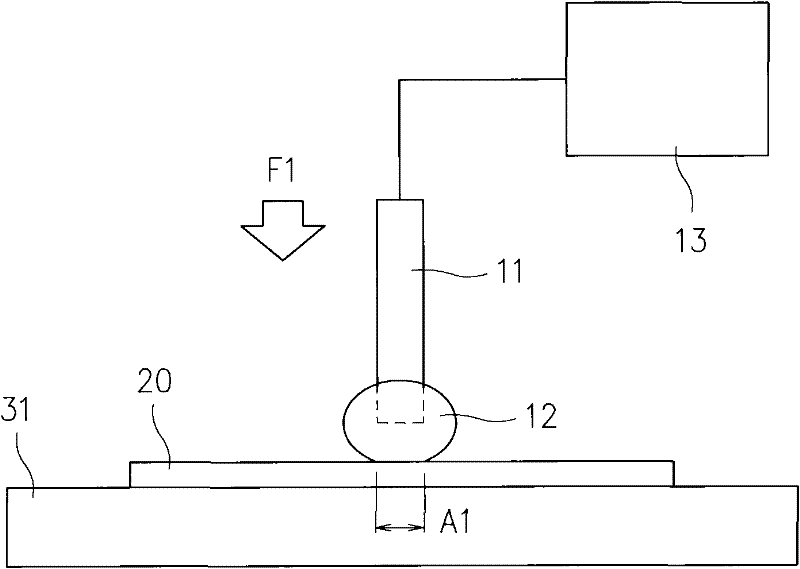

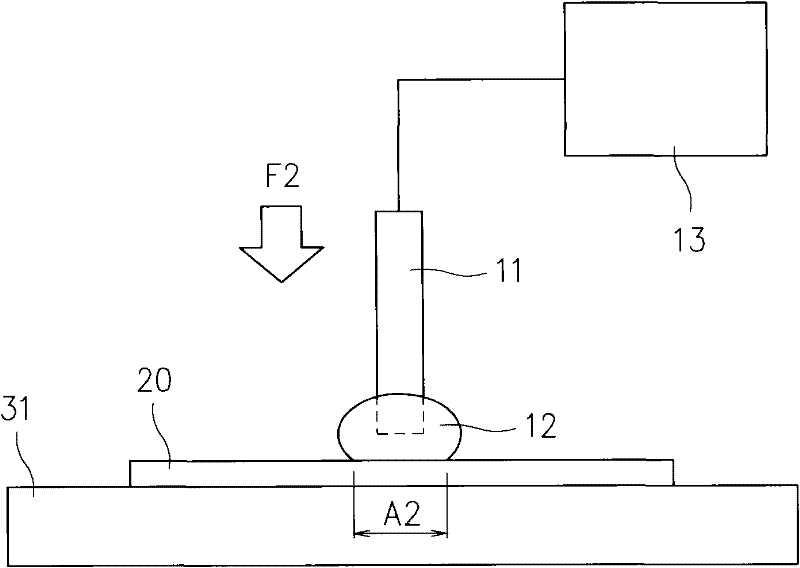

[0030] see figure 1 The schematic diagram of the structure of the embodiment of the test device of the present invention is shown. The test device 10 includes a support element 11, and one end of the support element 11 is provided with a contact pressure element 12. The contact pressure element 12 is made of elastic material, such as silica gel. , the touch element 12 is a spherical body, the support element 11 is connected to a driving device 13, and the drive device 13 is used to drive the support element 11 to move, so that the touch element 12 and a touch panel 20 are in contact with or s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com