Low-stiffness large-torsion metal film type coupling

A high-torque, low-stiffness technology, applied in the field of elastic couplings, can solve problems such as increased manufacturing costs of couplings, low angular displacement compensation capability, poor buffering and vibration damping performance, etc., and achieves obvious vibration isolation effect and angular The effect of low rigidity and large torque transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

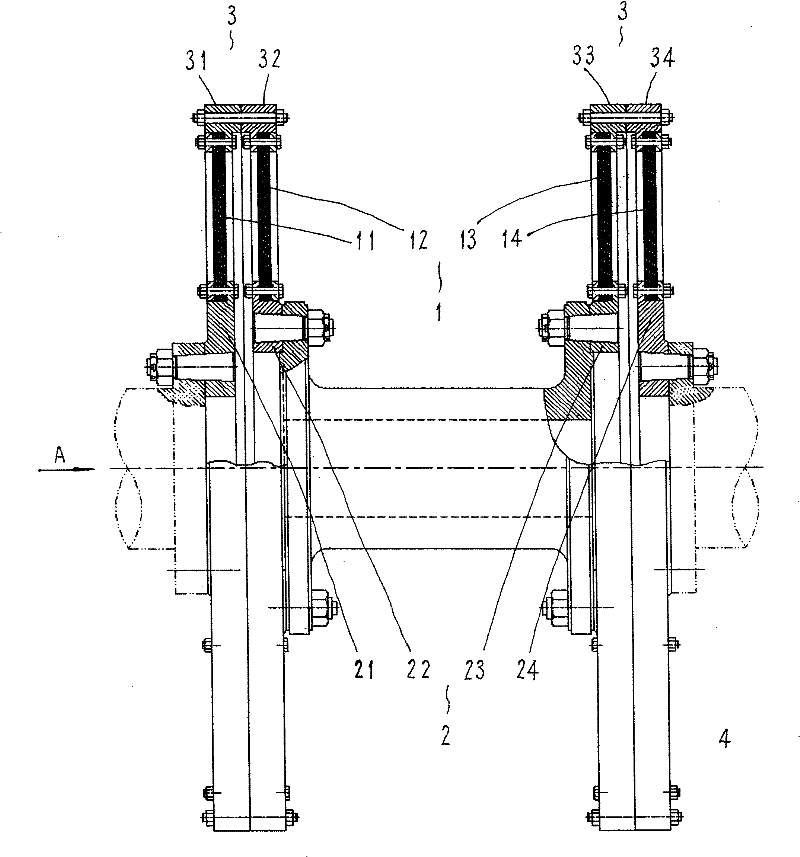

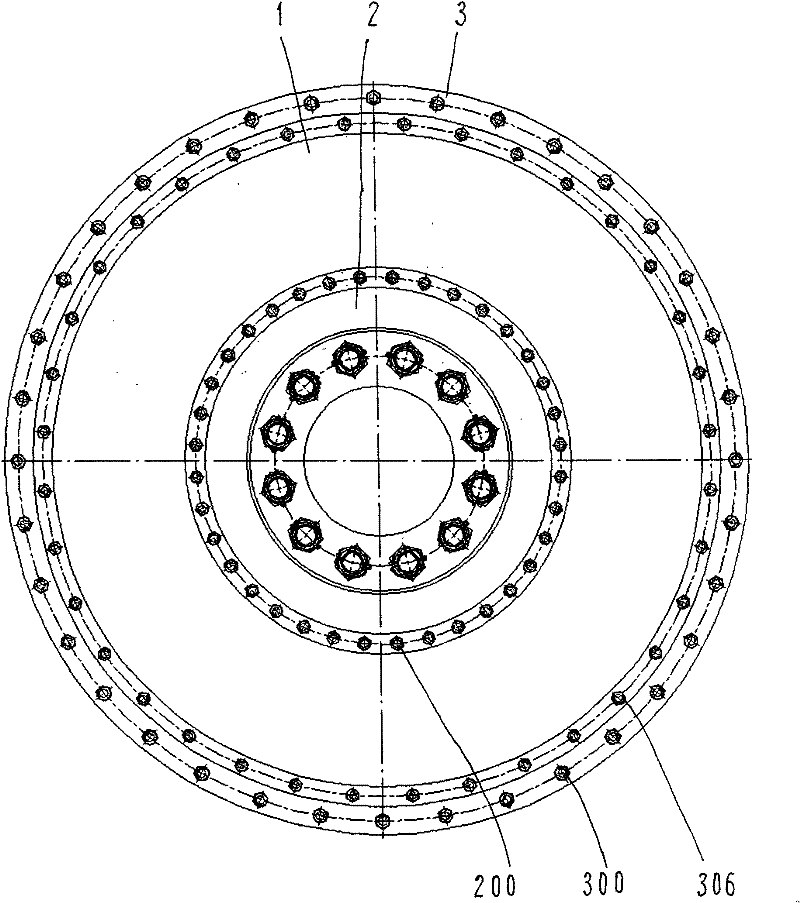

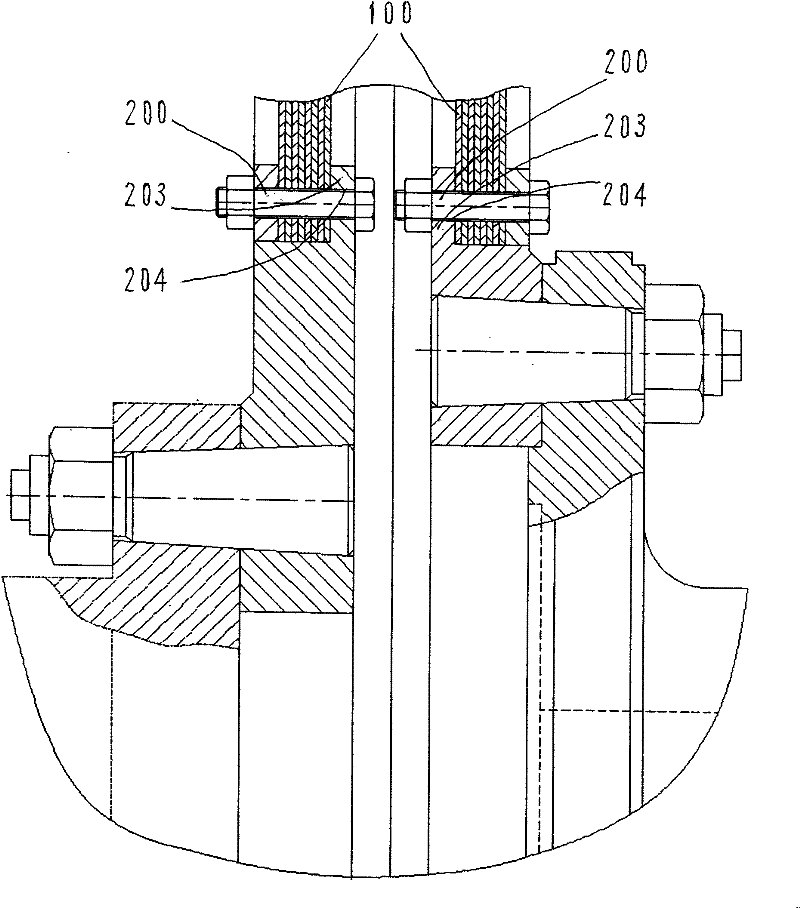

[0014] refer to figure 1 , as shown in the figure, the double-row low-rigidity and high-torque metal diaphragm coupling includes a metal diaphragm group 1, an inner flange 2, an outer clamping ring 3 and an intermediate shaft 4, and consists of two metal diaphragm groups 1 and 2 The inner flange 2 and two outer clamping rings 3 form a single-row low-rigidity and high-torque metal diaphragm coupling, and then an intermediate shaft connects two single-row low-rigidity and high-torque metal diaphragm couplings to form a double row Low-rigidity and high-torque metal diaphragm couplings, usually the single-row structure is inferior to the double-row structure in the ability to compensate for the lateral deviation of the shaft system and the vibration isolation capability. The following is an example of a double-row structure:

[0015] The metal diaphragm group 1 includes the first diaphragm group 11 and the second diaphragm group 12 in the previous row, the third diaphragm group 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com