Super-large span peripheral simply-supported prestressed double-layer and three-layer combined torsional reticulated shell structure

A twisted reticulated shell and prestressed technology, which is applied in the direction of building structure and construction, can solve the problems of reducing steel consumption, increasing construction difficulty, increasing the number of rods, etc., to achieve reduced steel consumption, good structural integrity, The effect of reducing the amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

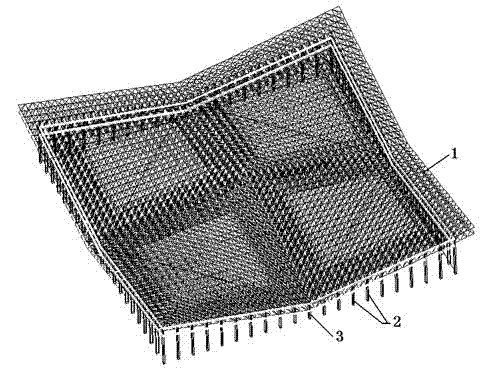

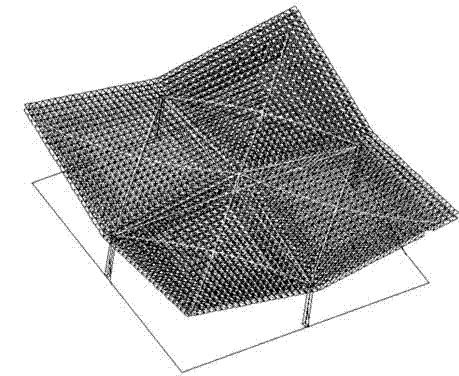

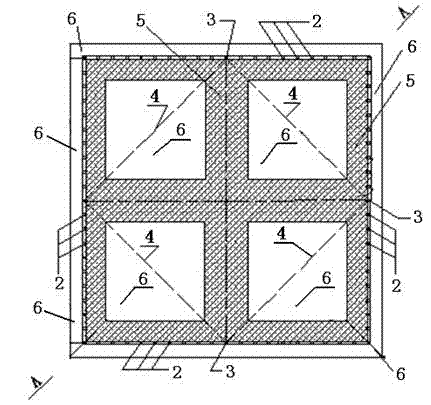

[0024] Example 1. like figure 1 As shown, this embodiment is a super-large experimental hall. The plane size of the twisted mesh shell 1 is 150m × 150m, square, the column spacing of the column net is 7.5m on each side, and the length of each side is 20 × 7.5m=150m. Each side of the twisted mesh shell 1 is provided with 20 side frame columns 2 and 1 central frame column 3 with different heights, a total of 21 frame columns. The height of the central frame column 3 is the lowest, the height of the frame column 2 at the corner of the twisted reticulated shell 1 is the highest, and it is raised from the middle to both ends to form a 10° clip horn. The cantilevered parts of the twisted mesh shell 1 are simply supported on the top of the frame column 2 . The prestressed steel cables 4 are arranged on the top support nodes of the central frame columns 3 on each side of the twisted reticulated shell 1, which is also the lowest point of the entire twisted reticulated shell struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com