Device for introducing threads to threading hook for running stitch embroidery robot

A robot and hook device technology, applied in embroidery machines, embroidery machine mechanisms, sewing equipment, etc., can solve problems such as manual threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

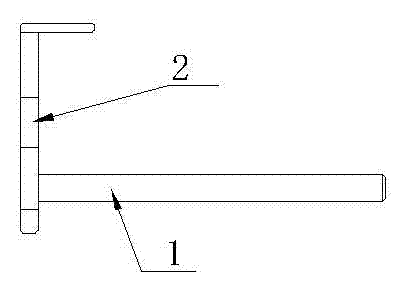

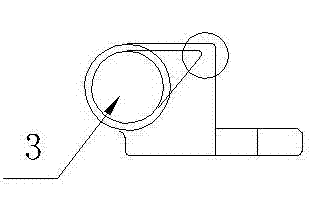

[0008] The thread introduction threading hook device structure of the single-needle embroidery robot of the present invention is as follows: figure 1 and figure 2 As shown, one end of guide shaft 1 is vertically equipped with guide plate 2, and the upper end of guide plate 2 is provided with a thread guide hole 3, and the line guide threading hook device is fixed on the threading base, and is used to lead the line into the threading hook.

[0009] The traditional computerized embroidery machine does not have this part. In the embroidery process, multi-needle embroidery is used, and the color is changed by changing the needle. There is no device for automatically introducing the thread into the pinhole, and the function of automatic threading cannot be realized. The needle is manually inserted into the thread. hole, inconvenient operation, time-consuming and labor-intensive, and low work efficiency. The embroidery robot adds a threading hook device to the traditional embroide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com