Immersion type coating device

A technology of a coating device and a driving device, which is applied to the device and coating of the surface coating liquid, which can solve the problems of easy contamination, increase product manufacturing cost, and reduce product yield, so as to improve quality and reduce cost , save the effect of transshipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

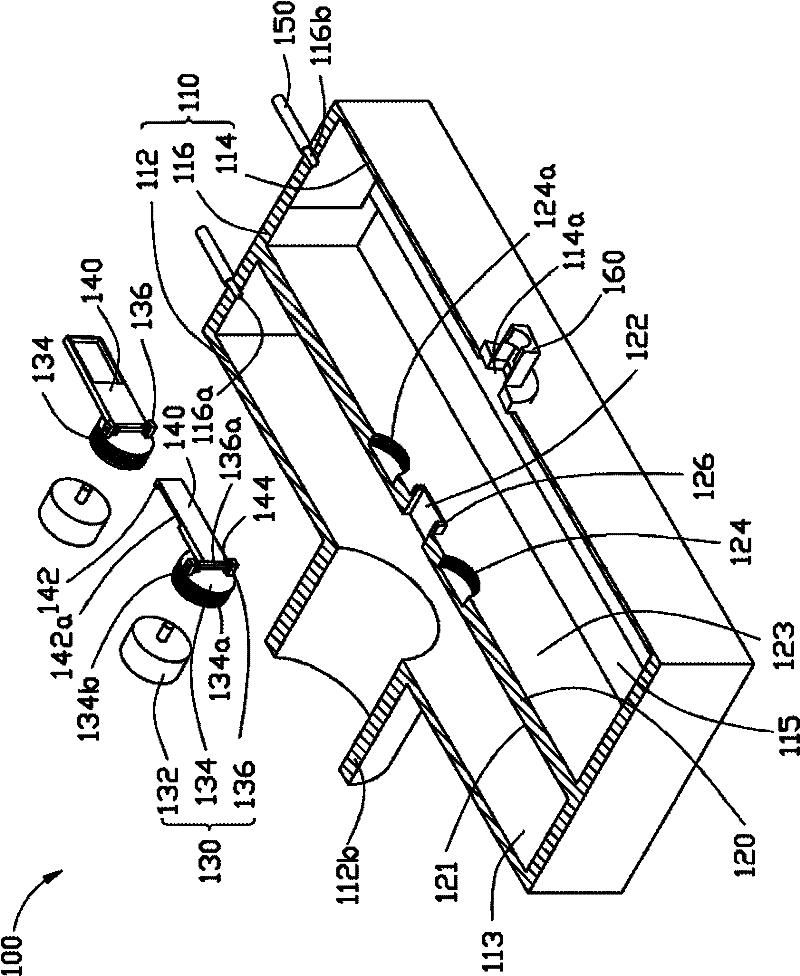

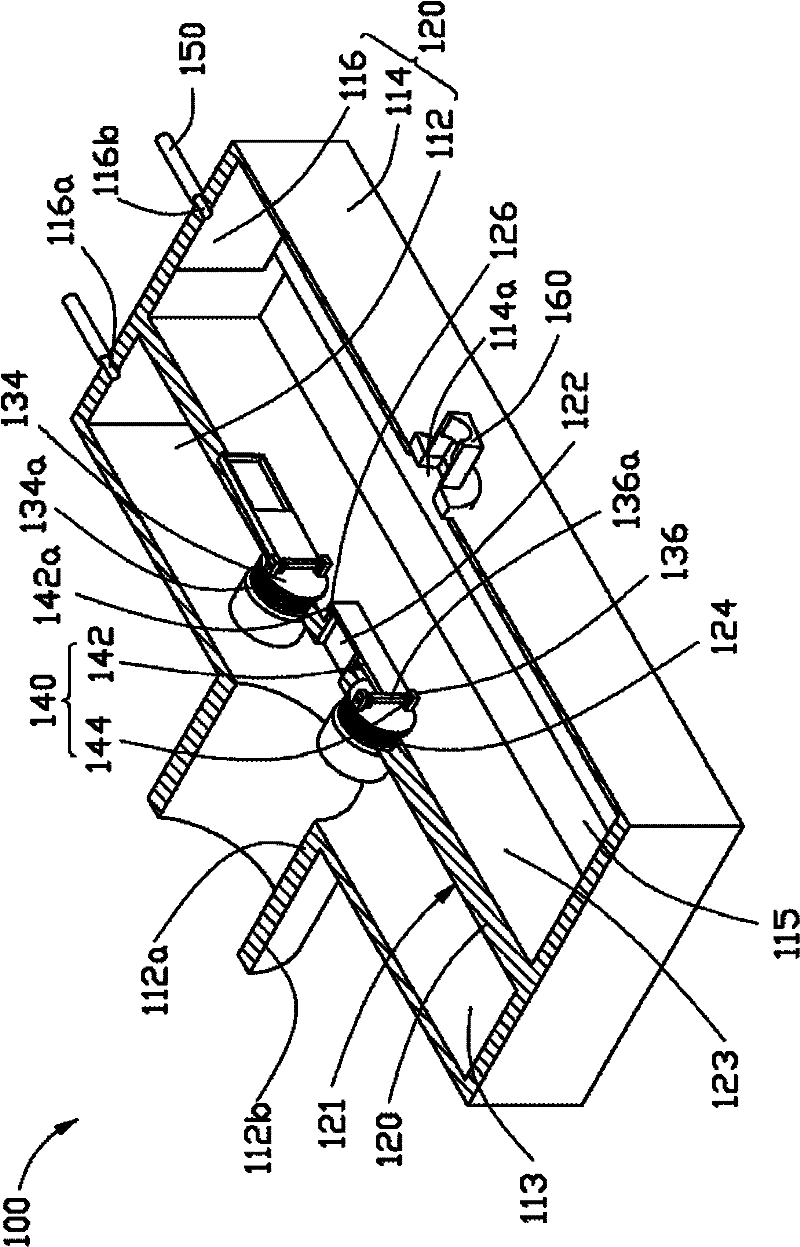

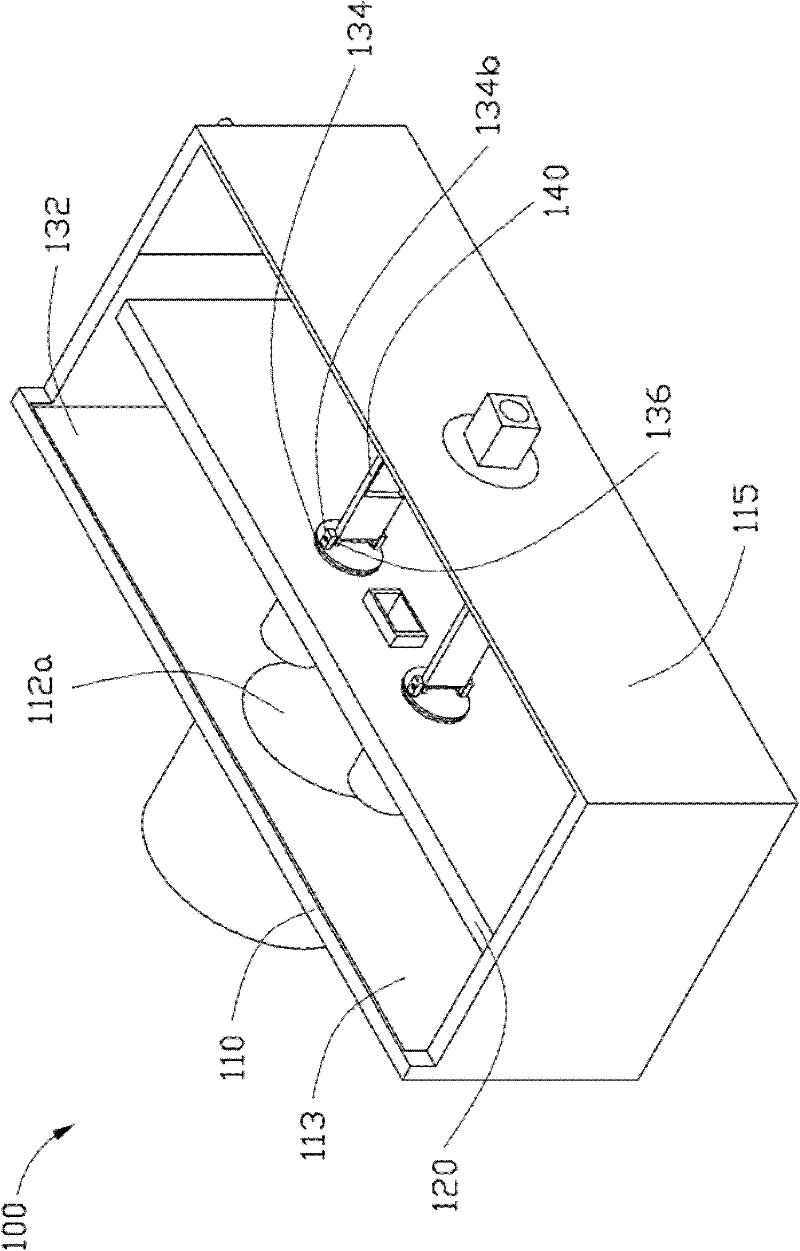

[0043] see figure 1 and figure 2 , a preferred embodiment of the present invention provides an immersion coating device 100, which includes a coating box 110, a partition 120, at least one driving device 130, at least one coating base 140, at least one intake pipe 150, and A feed valve 160. The partition 120 is arranged in the coating box 110 to divide the coating box 110 into a first cavity 113 and a second cavity 115 which are independent of each other. An opening 122 passing through the partition 120 is disposed on the partition 120 to communicate with the first chamber 113 and the second chamber 115 . The at least one driving device 130 is arranged on the partition 120 . The at least one coating base 140 is connected to the driving device 130 and located in the second cavity 115 , and can cover the opening 122 of the partition 120 driven by the driving device 130 . The at least one air inlet pipe 150 is disposed on the side wall of the coating box 110 corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com