W-shaped rutting bump height measuring system

A kind of rutting and die-testing technology, applied in the direction of measuring devices, instruments, material inspection products, etc., can solve the problems of inconsistent thickness, not considering the depth of rutting, unable to obtain anti-rutting performance, etc., and achieve the effect of accurate dynamic stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

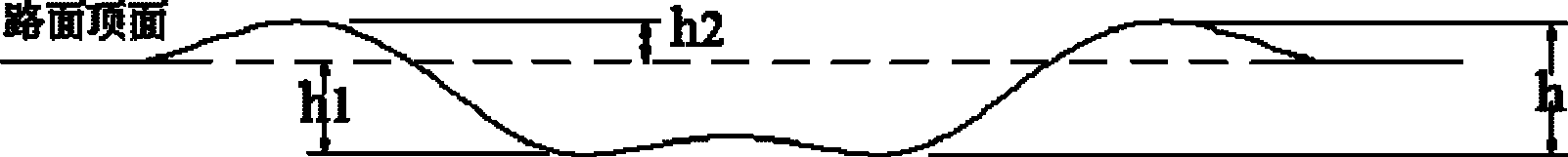

[0025] see Figure 1-3 , W-type rut testing system on the rutting instrument with double wheel group pneumatic tires, tire size, tread, inflation pressure and the distance between the tires can be adjusted (the wheel fixing shaft can be removed from the wheel fixing frame and installed Fixed, the wheel fixing shaft is a threaded steel shaft, two screws can fix a tire at any position on the shaft, and the two tires use the same fixing method, so that the distance between the two tires can be adjusted arbitrarily. The distance can be measured with a vernier caliper. After adjusting the distance between the wheels, install the fixed shaft of the wheel on the fixed frame of the wheel). On the lifting arm, simulate the rutting groove formed by the car on the road surface on the full-thickness rutting specimen (the specimen is the test mold, according to the required size, and the custom mold is customized). The pressure distribution of the pneumatic tire is uneven, and the double-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com