Herringbone shutter unit section

A herringbone and profile technology, which is applied in the direction of shading screens, windows/doors, special equipment for doors/windows, etc., can solve the problems of large cross-sectional area, high cost, and unsmooth drainage channels, and achieves reduced mold opening costs and high profile The effect of small cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

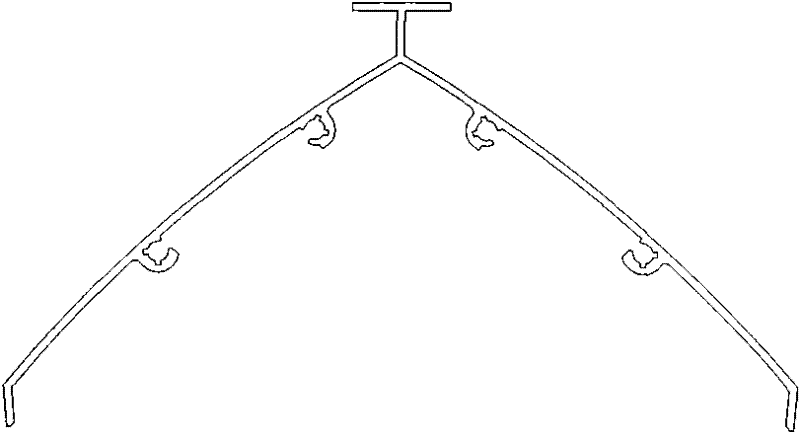

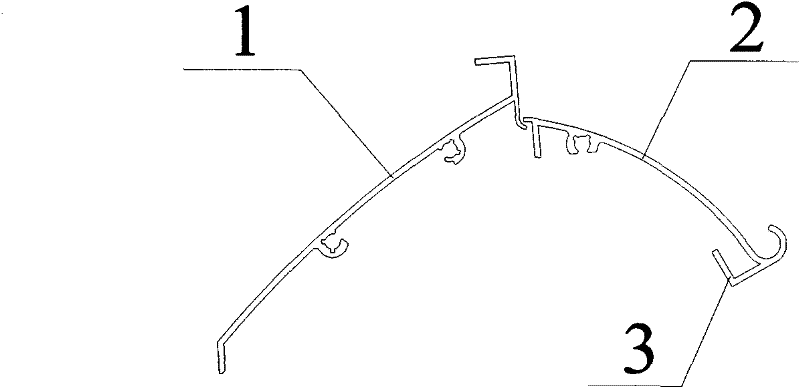

[0019] A herringbone louver unit profile, its structure is as follows figure 2 As shown, the profile is composed of a left louver 1 and a right louver 2, the length of the right louver 2 is shorter than that of the left louver 1, the two louvers form a herringbone profile, and the bottom of the right louver 2 is hook-shaped structure, the bottom is provided with a sump 3 on the outside, and common louver blades such as figure 1 As shown, the structures of the louvers on the left and right sides are symmetrical.

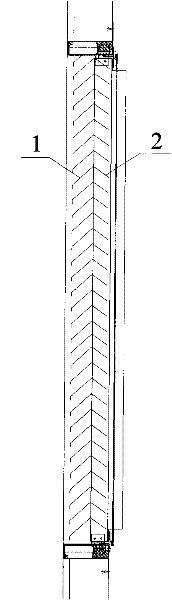

[0020] When installing, the louver profiles are distributed at equal intervals, and the two ends are fixed to the vertical rods by screws, which constitutes the louver unit. Its structure is as follows: image 3 shown. The bottom of the right louver 2 is clamped in the waist hole 5 of the vertical rod 4 of the louver unit. Its structure is shown in Figure 5. In this way, the effect of tapping and fixing can be achieved. The rainwater is discharged without flowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com