Efficient cyclic purification and phosphorization device

A circular purification and high-efficiency technology, applied in chemical instruments and methods, filtration circuits, filtration and separation, etc., can solve the problems of pumping tanks, electricity and labor, affecting the quality of phosphating, and cannot be recycled and reused, so as to achieve guaranteed results and save manpower The effect of electricity bills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

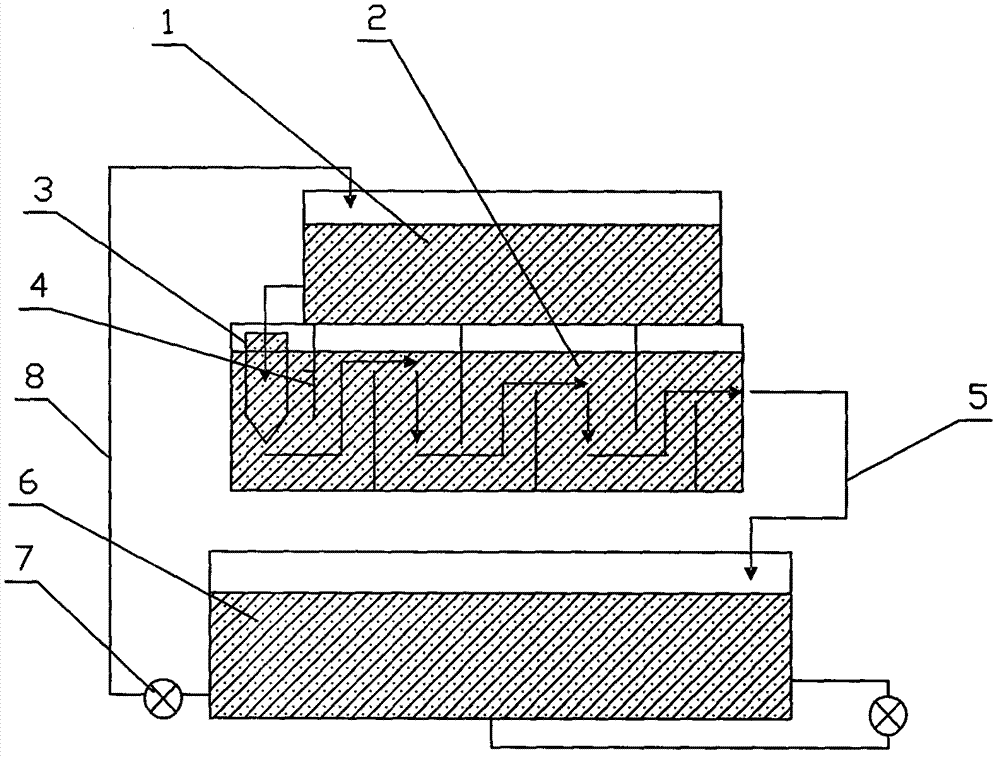

[0012] The present invention includes a phosphating working tank 6, a lifting pump 7, a lifting pipeline 8, and a settling tank. The phosphating working tank 6 is connected to a settling tank through the lifting pipeline 8, and the settling tank includes an automatic liquid replenishment tank 1 and a plurality of connected settling tanks 2. The automatic liquid replenishment tank 1 is connected with the lifting pipeline 8; the settling tank 2 is separated by multiple baffles 4 arranged on the upper and lower sides of the settling tank 2; several filter bags 3 are arranged in the first settling tank, and the liquid replenishing tank The phosphating solution in 1 flows into the filter bag 3 through several pipelines equipped with flow control valves; the terminal settling tank 2 is provided with a return pipe 5 communicating with the phosphating working tank 6 .

[0013] The filter bag 3 is a multi-layer filter bag 3 structure, wherein the automatic liquid replenishment tank 1 pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com