Nontoxic, odorless and recoverable environmentally-friendly polyurethane foaming material and preparation method thereof

A polyurethane, odor-free technology, applied in coatings and other directions, can solve problems such as excessive foaming of the core layer, optimizing the mechanical properties of materials, and inability to reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

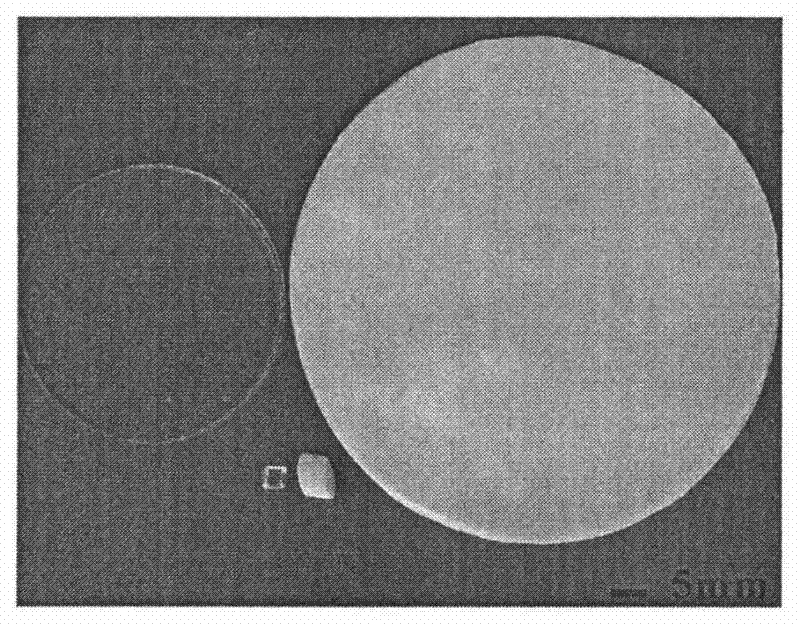

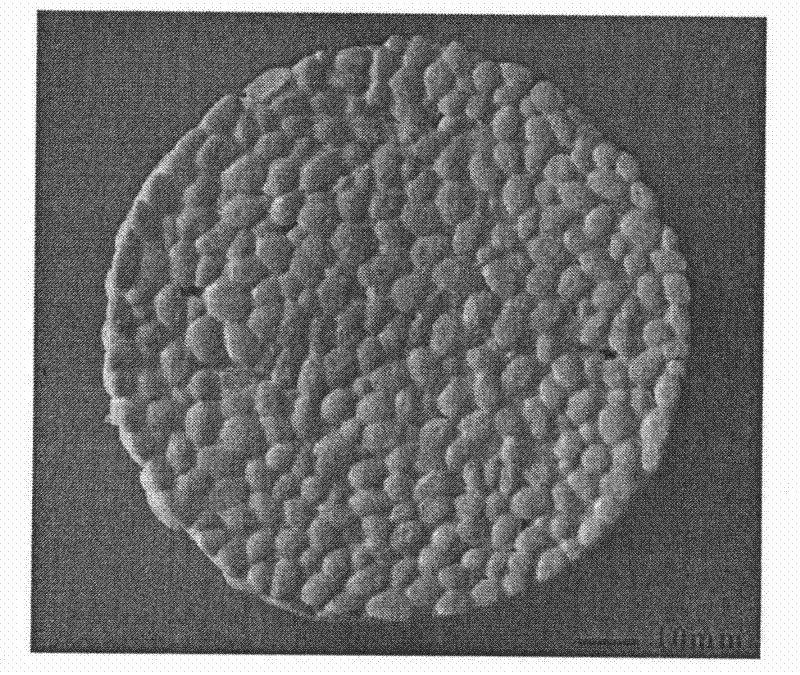

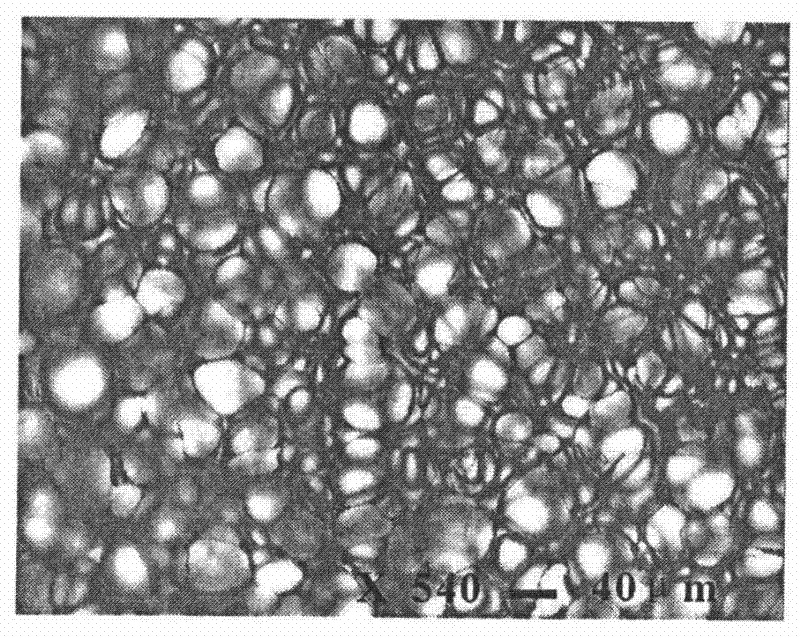

[0045] Different kinds of polyurethane raw material particles are respectively placed in the high-pressure mold of the molded physical gas foaming device to ensure that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. When the mold reaches the set temperature, a certain pressure of N 2 or CO 2 , constant temperature and pressure for a period of time, and then release the pressure to normal pressure at a certain speed. The foamed material was taken out and subjected to optical microscope analysis and density measurement, the results are shown in Table 1.

[0046] Table 1 Comparison of structural properties of foamed materials of different types of polyurethane raw materials

[0047]

Embodiment 2

[0049] Place No. 2 and No. 3 samples in the high-pressure mold of the physical gas foaming device, so that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. When the mold reaches the set temperature, fill it with 20MPa N 2 , kept at constant temperature and pressure for a certain period of time, and then released to normal pressure at a speed of 28MPa / s. The foamed material was taken out and subjected to optical microscope analysis and density measurement, the results are shown in Table 2.

[0050] Table 2 Comparison of structural properties of polyurethane foam materials prepared at different foaming temperatures

[0051]

Embodiment 3

[0053] Place the No. 2 sample in a high-pressure mold in a molding physical gas foaming device to ensure that the total particle volume does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. When the mold reaches 160°C, fill it with 10MPa N 2 , kept at constant temperature and pressure for a period of time, and then released to normal pressure at a rate of 15MPa / s. The foamed material was taken out and subjected to optical microscope analysis and density measurement, the results are shown in Table 3.

[0054] Table 3 Comparison of structural properties of polyurethane foam materials prepared with different holding times

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com