Cleaning method of uranium hydrometallurgy fixed bed ion exchange resin

An ion exchange resin and ion exchange technology, applied in the direction of ion exchange bed cleaning/flushing, ion exchange, ion exchange regeneration, etc., can solve the problems of inconvenient operation, large resin loss, and inability to disperse resin, and achieve low crushing rate and easy operation. Convenience and low resin loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

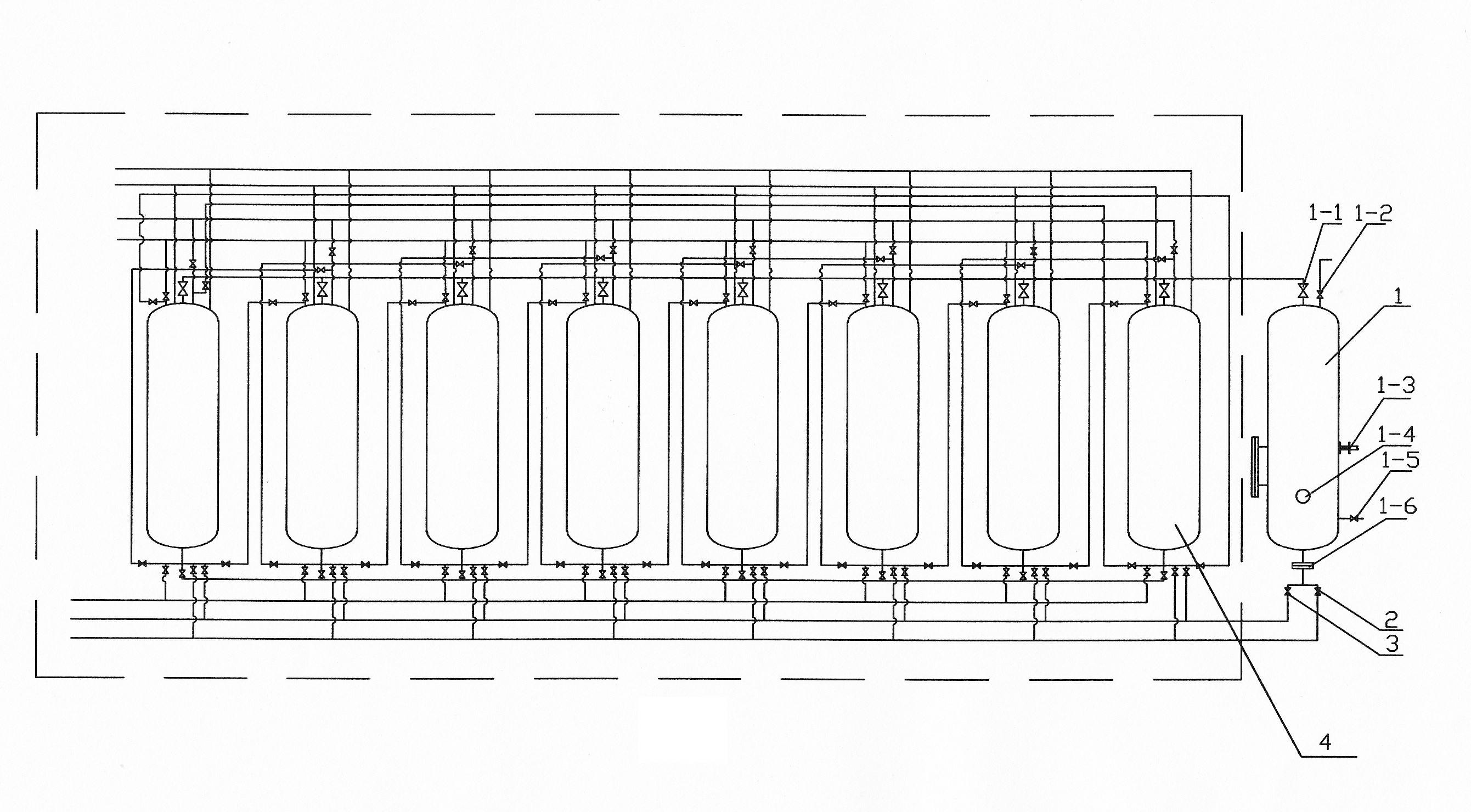

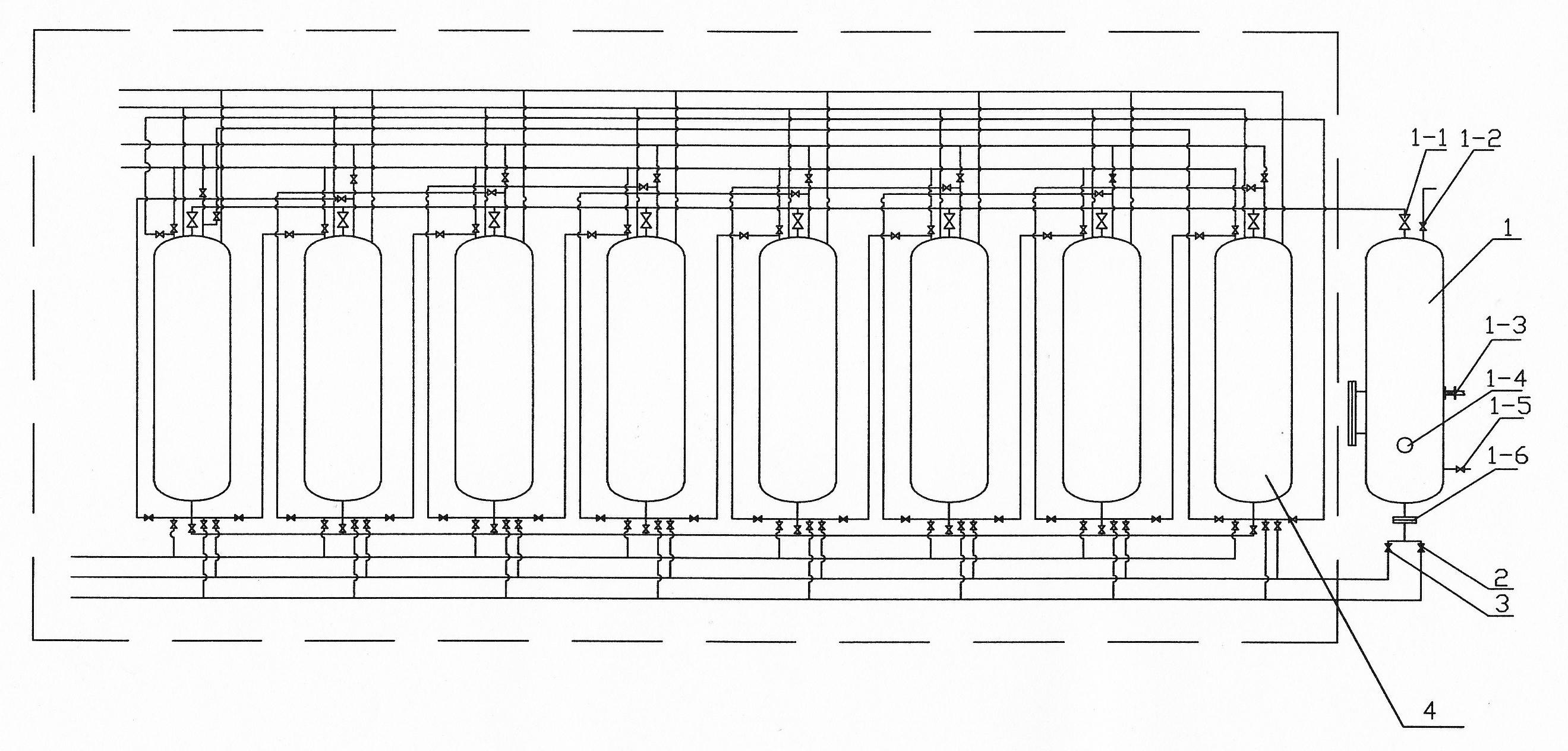

[0016] A cleaning method for uranium hydrometallurgical fixed bed ion exchange resin, which is to set an independent cleaning tower 1 outside the uranium hydrometallurgical fixed bed ion exchange system, and clean the resin in the exchange tower 4 that needs to be cleaned through the cleaning tower 1 . In this embodiment, the uranium hydrometallurgical fixed bed ion exchange system includes eight fixed bed ion exchange towers 4.

[0017] The specific operation process is as follows:

[0018] A. Connect the exchange tower 4 in the fixed bed ion exchange system with the resin transfer shut-off valve 1-1 on the cleaning tower 1 through a pipeline, and then open the resin transfer shut-off valve 1-1, and use backflush water to clean the exchange tower The resin in 4 is introduced into the cleaning tower 1 through the resin transfer stop valve 1-1, and the resin transfer stop valve 1-1 is closed after the resin transfer is completed.

[0019] B. Open the exhaust and drain valve 1-2 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com