Waste incinerator

A garbage incinerator and garbage technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of low garbage combustion value, single function, high investment cost, etc., achieve complete garbage incineration, fast burning speed, and improve combustion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

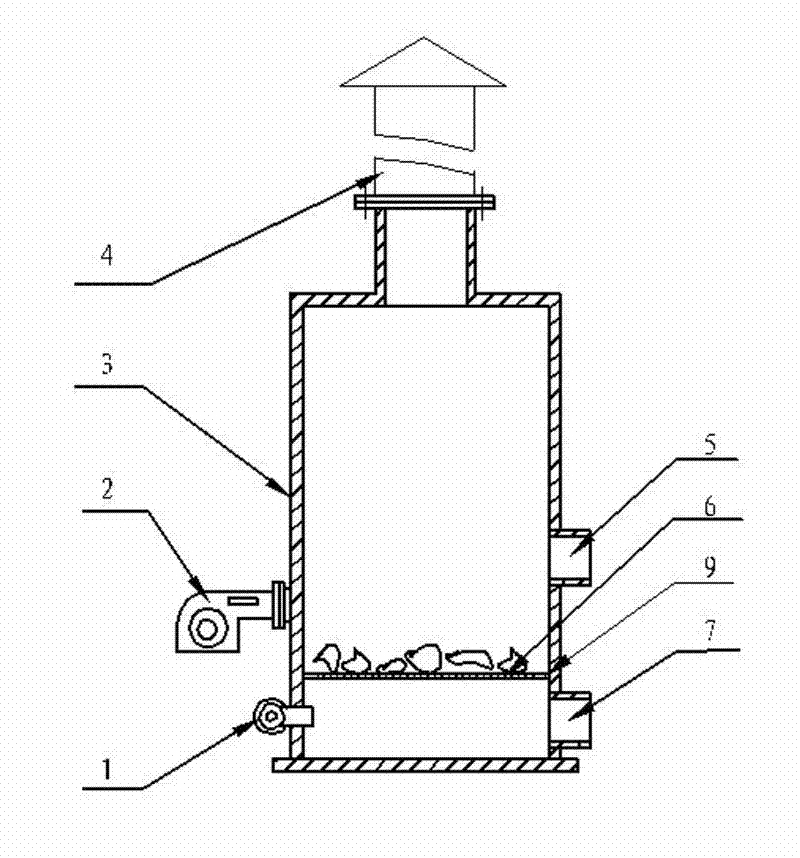

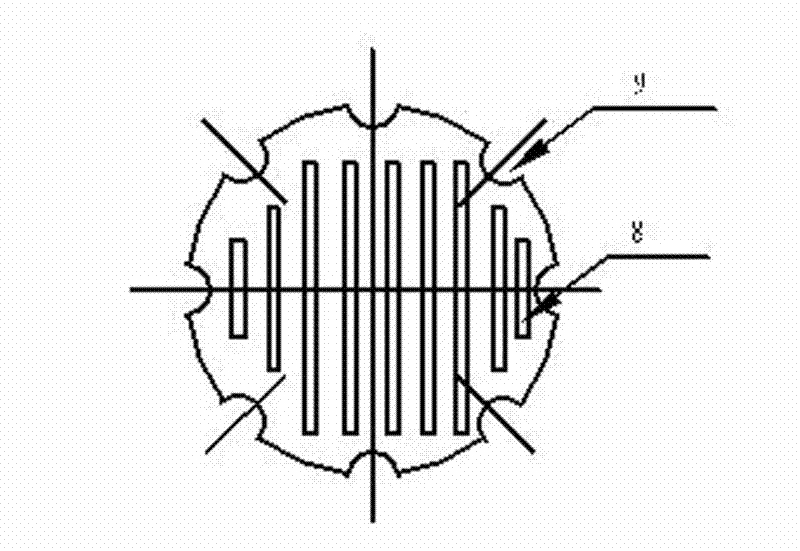

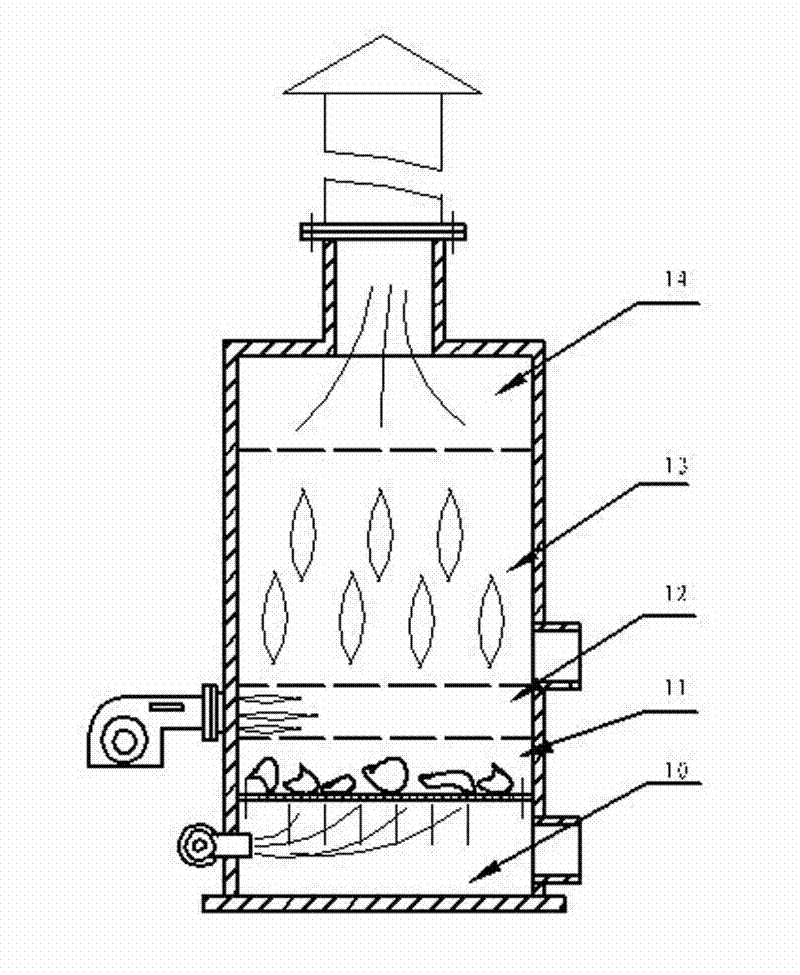

[0021] As shown in the accompanying drawings, a small-scale garbage incinerator includes a furnace body 3, a blower 1, a burner 2, a garbage inlet 5, a fire grate 6, a slag outlet 7, and a chimney 4; wherein the fire grate 6 is provided with an ash drop hole 8 And hot air hole 9. The blower 1, the burner 2, the fire grate 6 and the chimney 4 are fixed on the furnace body 3; the furnace body 3 is provided with a garbage inlet 5 and a slagging outlet 7.

[0022] The working condition of the furnace body 3 is formed by an oxygen feeding and slag falling area 10 , a molten layer 11 , an ignition and combustion supporting area 12 , an incineration area 13 and a smoke collecting area 14 .

[0023] Garbage is put into the incineration furnace from the garbage inlet 5, the burner 2 is automatically ignited, and the garbage is ignited to enter the incineration state. After the furnace reaches a certain temperature, the burner 2 automatically turns off and the garbage is burned independ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com