Method for retracting surplus hydraulic supports of fully mechanized mining face

A fully mechanized mining face and hydraulic support technology, which is applied in pillars/supports, mining equipment, earthwork drilling and mining, etc., can solve problems that are not worth popularizing, many manpower, material resources, long time, etc., and achieve wide practicability and process Simple, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

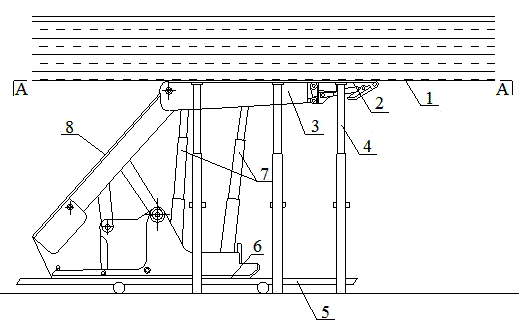

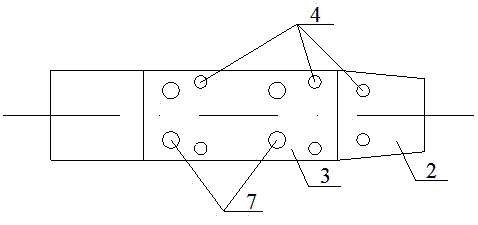

[0015] Such as figure 1 As shown, the method for retracting redundant hydraulic supports in the fully mechanized mining face of the present invention: first, utilize the existing return column winch of the return air level roadway to pull the hydraulic supports to the loading position 30-50m away from the end, and Position the hydraulic support 8 that needs to be retracted and slowly rise, so that the hydraulic support top beam 3 is in overall contact with the roadway roof 1. If the roof is not flat, you can add a backing plate or a road log; A plurality of single pillars 4 are arranged symmetrically below the 2. The number of multiple single pillars 4 is not less than 6, such as figure 2 As shown, there are four symmetrically arranged under the top beam 3 of the hydraulic support, and two symmetrically arranged under the front beam 2 of the hydraulic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com