Automatic separating bar shear for IC strips and separating bar shear method thereof

An automatic sorting and rib cutting machine technology, which is applied in metal processing and other fields, can solve the problems of increasing production cost, reducing production efficiency, and increasing the workload of inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

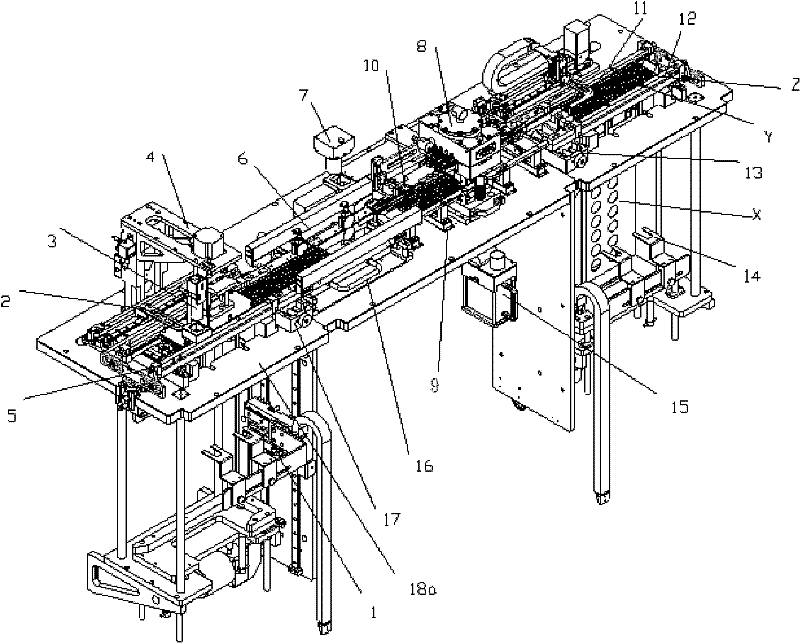

[0049] The features of the present invention will be further described in the form of preferred embodiments with reference to the accompanying drawings.

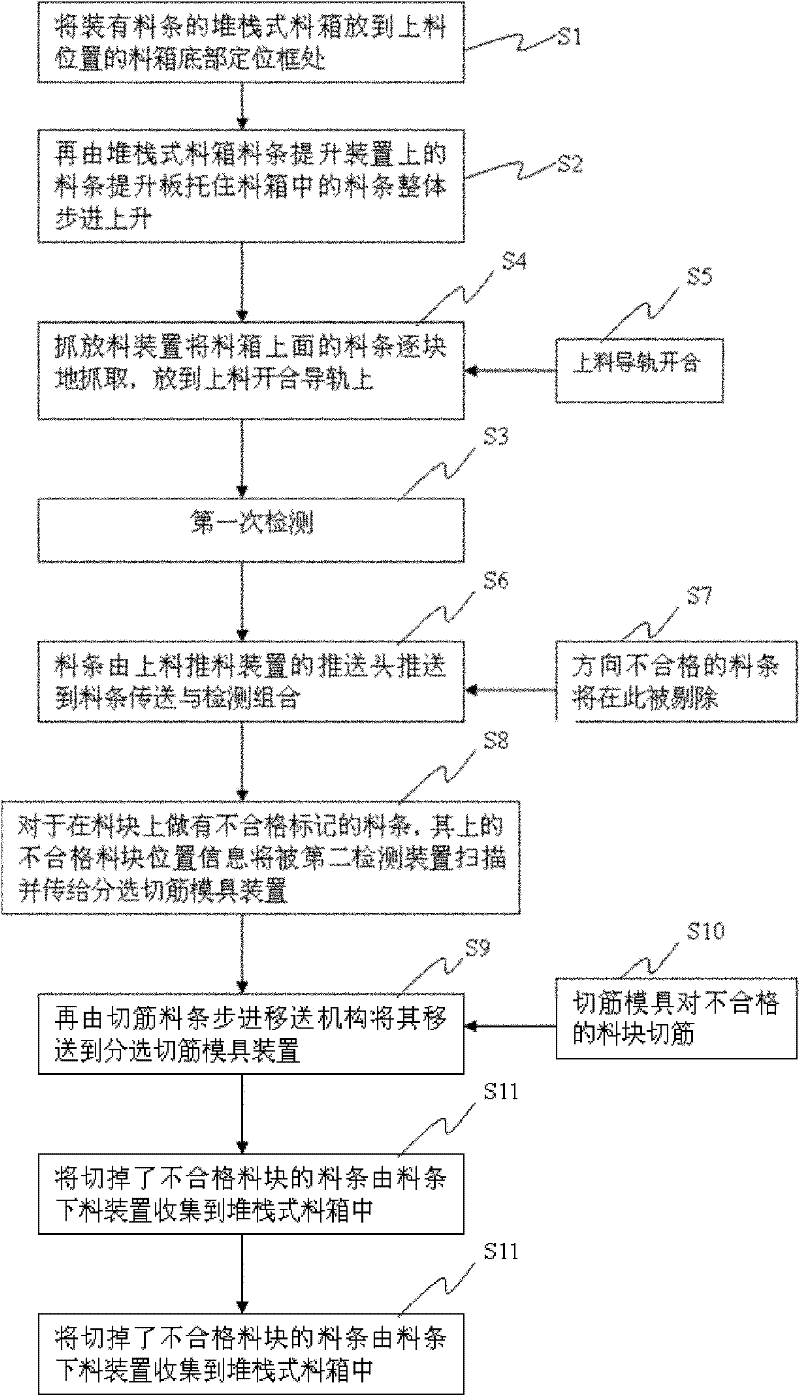

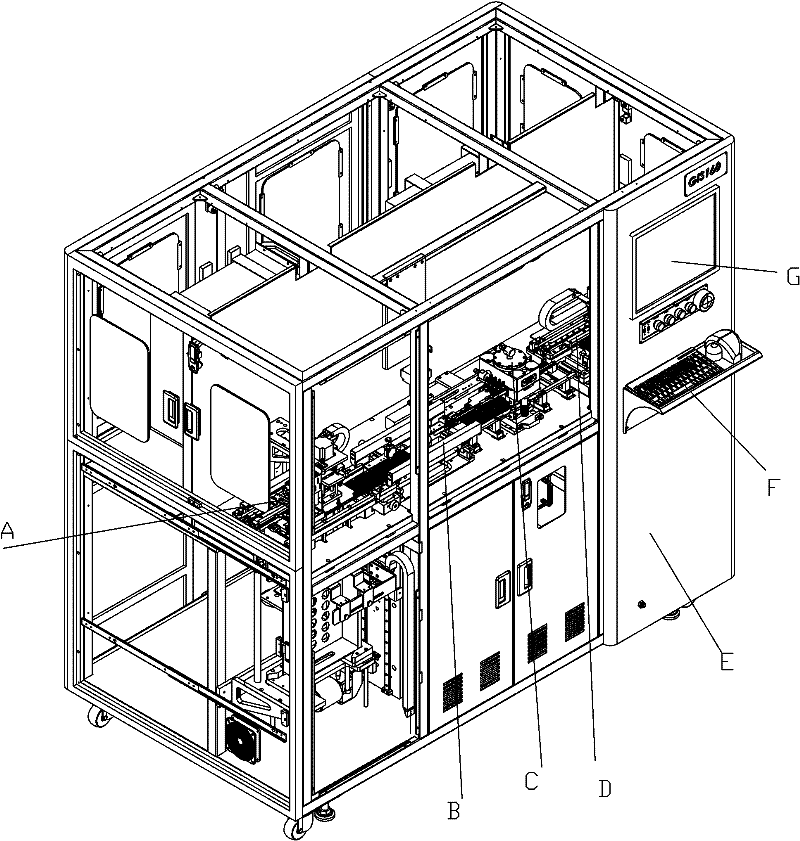

[0050] refer to Figure 1a , the IC material strip automatic sorting and rib cutting machine in the present invention works according to the following technological process, at first, the stacked feed box with the material strip is manually placed on the positioning frame at the bottom of the feed box at the feeding position, step S1; usually One box can be placed at a time, 180 strips per box, and the strips are directly stacked together; then the strips in the box are supported by the strip lifting plate on the strip lifting device of the stacked box, and the strips in the box are raised step by step as a whole, step S2 ; Grasp and release device grabs the material strips on the top of the material box piece by piece in step S4, and puts them on the opening and closing guide rail of loading material S5; after the first dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com