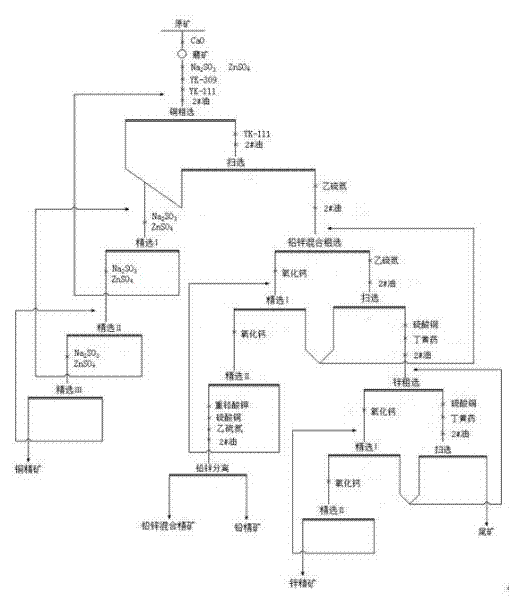

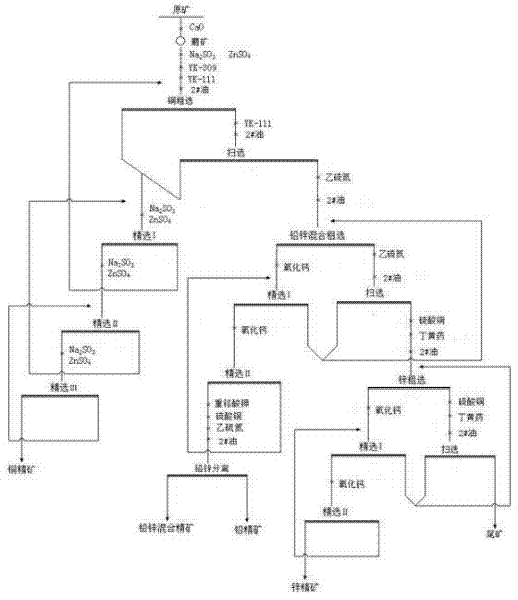

Ore-dressing method for separating copper, lead and zinc multi-metal complex ore embedded with fine grains

A beneficiation method and polymetallic technology, applied in the mineral sorting of lead and zinc complex ore, and the copper field, can solve the problems of high energy consumption, high mutual content of concentrates, toxic chemicals, etc., and achieve low energy consumption and good separation effect. , select the effect of high index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] The preparation method of the inhibitor yk-309 is as follows: mix carboxymethyl cellulose and sodium hydroxide at a weight ratio of 3 to 5:1, add pure water to dilute to a concentration of 15% to 20%, and then place In the reaction kettle, heat up to 90°C, keep it for 2 hours, and cool down to obtain the inhibitor.

[0080] The preparation method of the inhibitor yk-111 is as follows: firstly add 1 mole of isobutanol to the reactor, then add 0.1 mole of sodium thiocyanate, stir and heat up, and dropwise add 0.2 1 mole of propenyl chloride, drop it within 1 hour, heat up to reflux, and reflux at about 90-100°C for 2 hours, then add 0.01 mole of catalyst (RO) mTi (Cl) n(m+n=4), and then rise to Reflux at 110°C for 12 hours, cool and filter to remove the generated sodium chloride, distill off excess alcohol and halogenated hydrocarbons from the filtrate under reduced pressure, and the rest is the collector.

[0081] Described 2# oil is pine alcohol oil, composite higher a...

Embodiment 1

[0083] Using the "preferential copper-lead-zinc and other floatable" separation process of the complex copper-lead-zinc ore described in the present invention, a laboratory small-scale process test was carried out on the complex copper-lead-zinc ore in a mine, and a good separation was obtained. index.

[0084] A copper-lead-zinc polymetallic ore mainly contains copper, lead, zinc and precious metal silver, of which the copper grade is 0.54%, the lead grade is 2.01%, the zinc grade is 3.09%, and the silver grade is 125g / t. The nature of the ore is relatively complex, and the embedded particle size is relatively fine. The relationship between galena and sphalerite in the ore is very close. About 55% of the galena is wrapped by sphalerite, and sometimes it is also surrounded by tetrahedrite and pyrite. , quartz, etc., and the total amount of wrapped galena accounts for 68.30%. These galenas are difficult to completely dissociate from their carrier minerals. Especially, the galen...

Embodiment 2

[0088] A copper-lead-zinc polymetallic ore mainly contains copper, lead, zinc and silver, of which the grade of copper is 0.86%, the grade of lead is 3.63%, the grade of zinc is 5.35%, and the grade of silver is 226g / t. The symbiotic relationship of copper, lead and zinc minerals in this ore is very close, and the particle size of the mosaic distribution is very fine and uneven, and they are mosaic and wrapped with each other to form various structural structures. Therefore, it is difficult to achieve a high monomer dissociation degree in the grinding process. Coupled with the influence of secondary copper ions, the separation of copper, lead and zinc is difficult.

[0089] The raw ore is ground to -74μm by a ball mill, accounting for 85%. CaO1500g / t is added during the grinding process. The structure of the flotation process is: copper roughing stage, sweeping stage, and selection stage four; lead-zinc mixed roughing stage, sweeping stage , three stages of selection; one stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com