Device and method for scalding different parts of a poultry carcass with varying intensities

A poultry and carcass technology, applied in poultry processing, slaughtering, application, etc., can solve problems such as transmission of dirt, microorganisms and bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

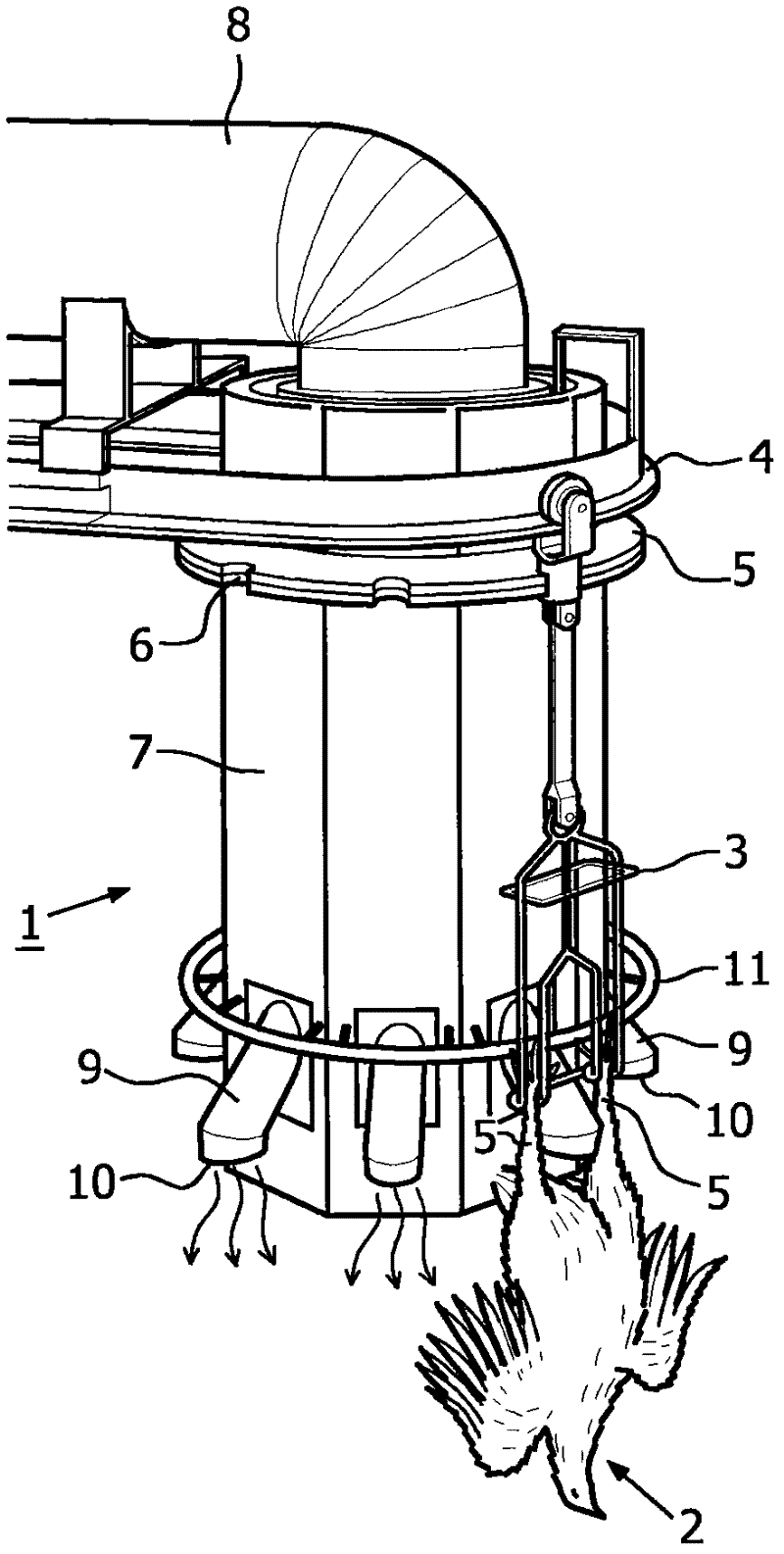

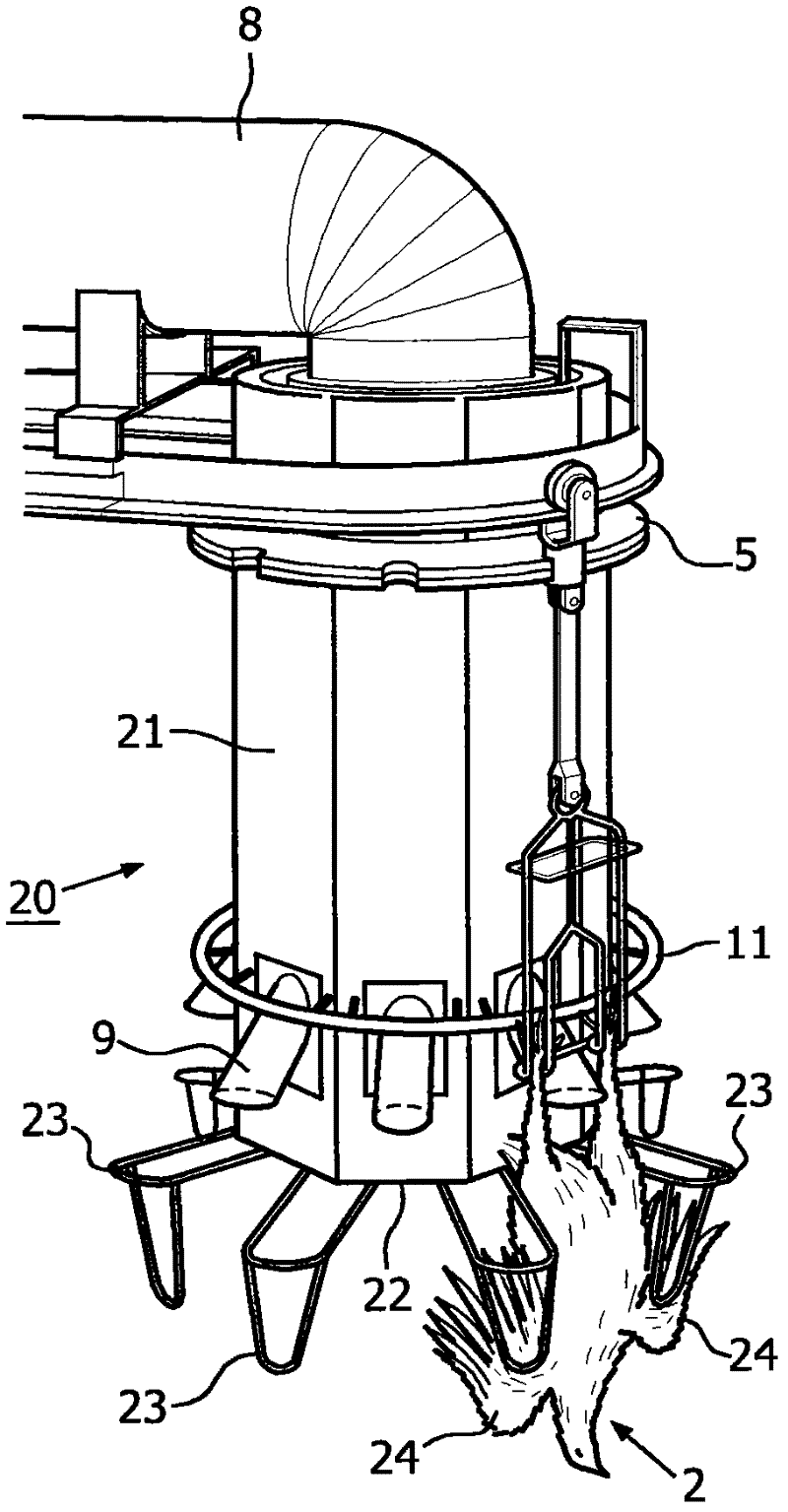

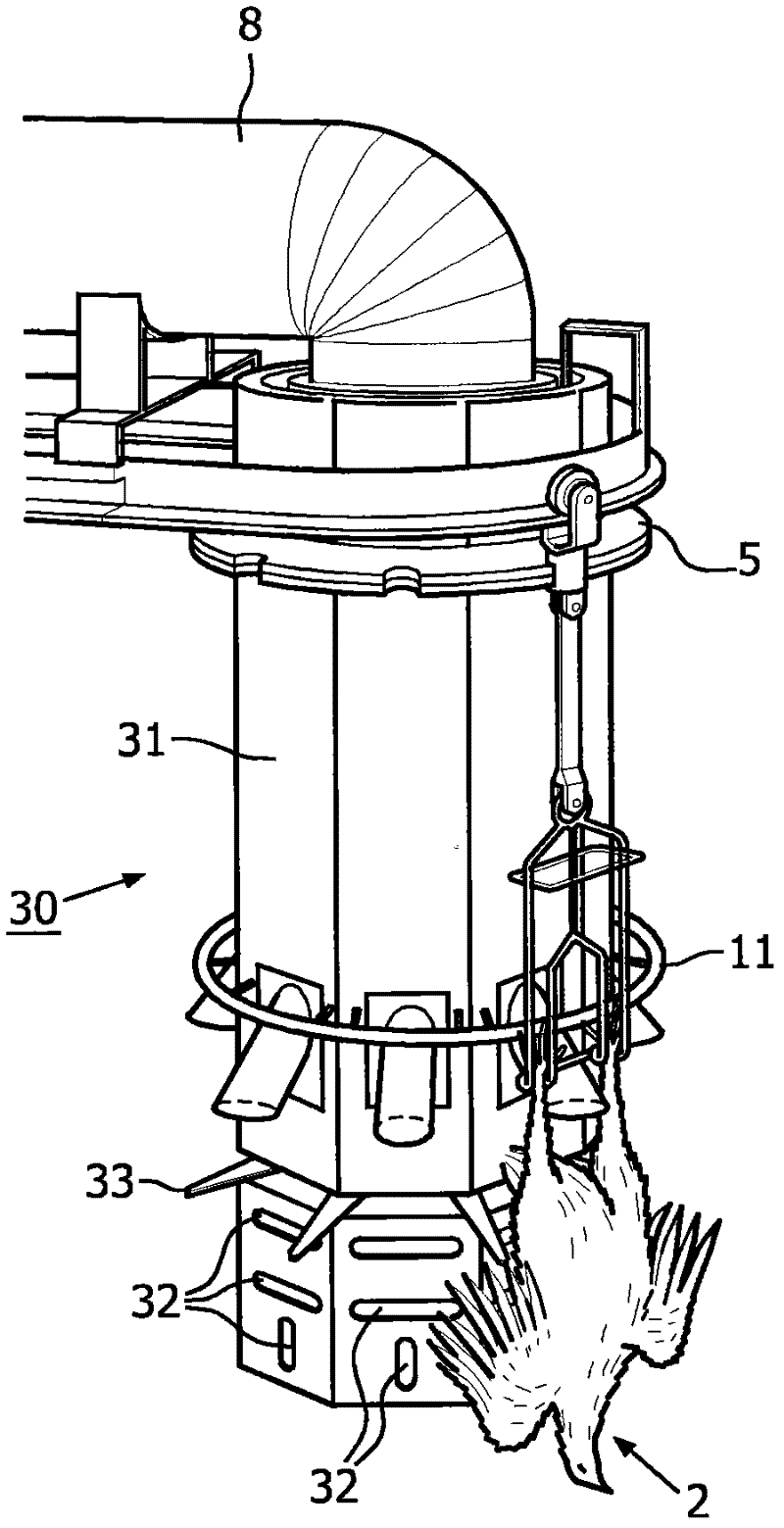

[0035] FIG. 1 shows a part of a processing space 1 in which a poultry carcass 2 is suspended on a conveying channel 4 by means of supports 3 . The poultry carcass 2 hangs upside down on legs 5 in the stand 3 . In the part shown, the conveying channel 4 passes through a bend in which deflecting wheels 5 with grooves 6 roll along the carriage 3 (only one of which is shown in this figure for the sake of simplicity). Air cylinder 7 is connected with reversing wheel 5, can supply scalding medium to air cylinder 7 through supply pipeline 8. A duct 9 with an outlet 10 is connected to the interior of the cylinder 8 , so that the scalding medium supplied through the supply duct 8 flows out of the duct 9 at the outlet 10 . This outflow of scalding medium is indicated by arrow P 1 shown schematically. As it passes through the bend, the poultry carcass 2 will thus be subjected to a flow of scalding medium directed towards the cloaca and tail (P 1 ) processing. The poultry carcass 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com