Integrated cable inlet-outlet sleeve

A technology for incoming and outgoing wires and bushings, applied in electrical components and other directions, can solve the problems of increasing the seal in place, increasing the air gap, increasing the width of the air box, etc., so as to reduce the risk of air leakage, reduce the width and size, and reduce the The effect of insulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

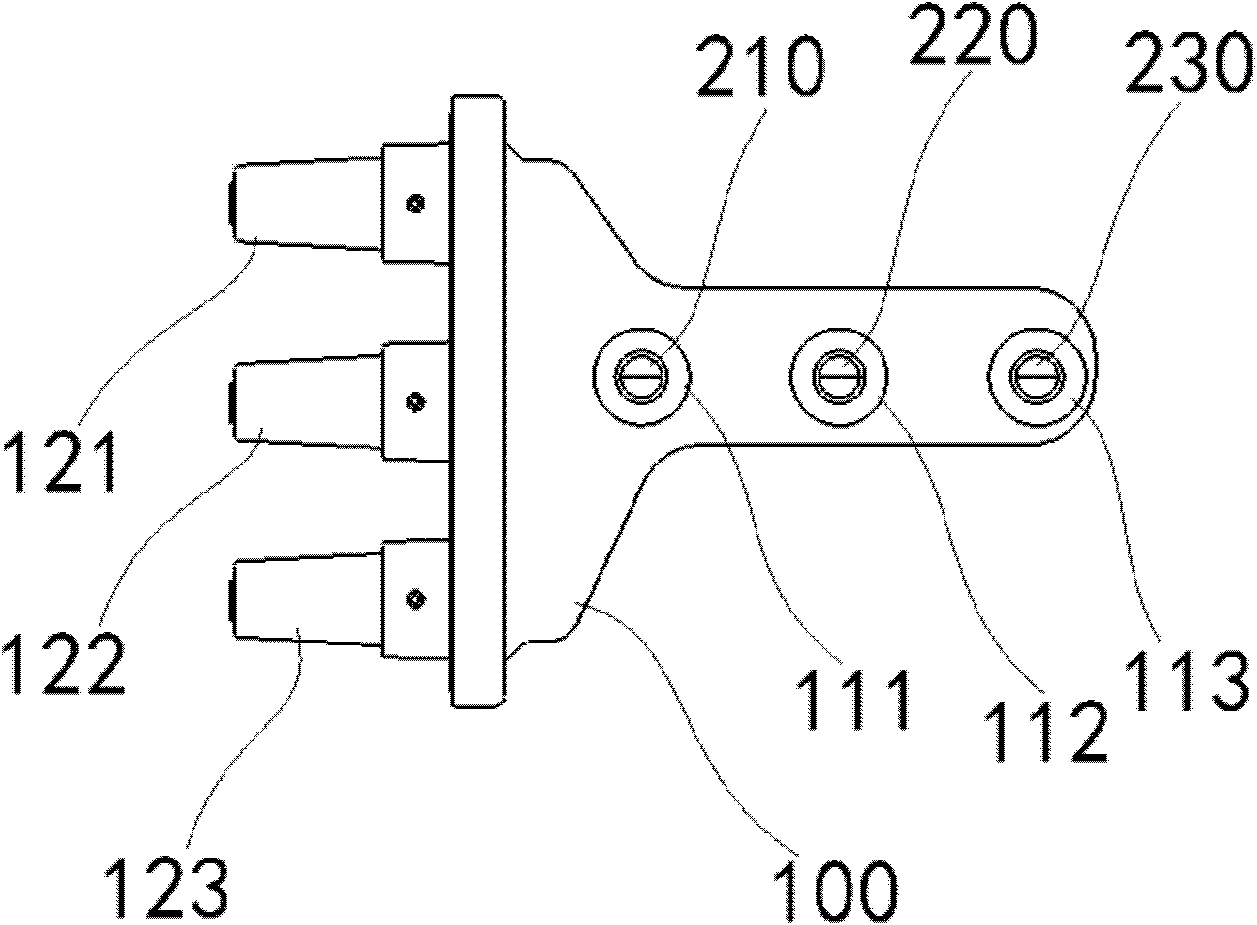

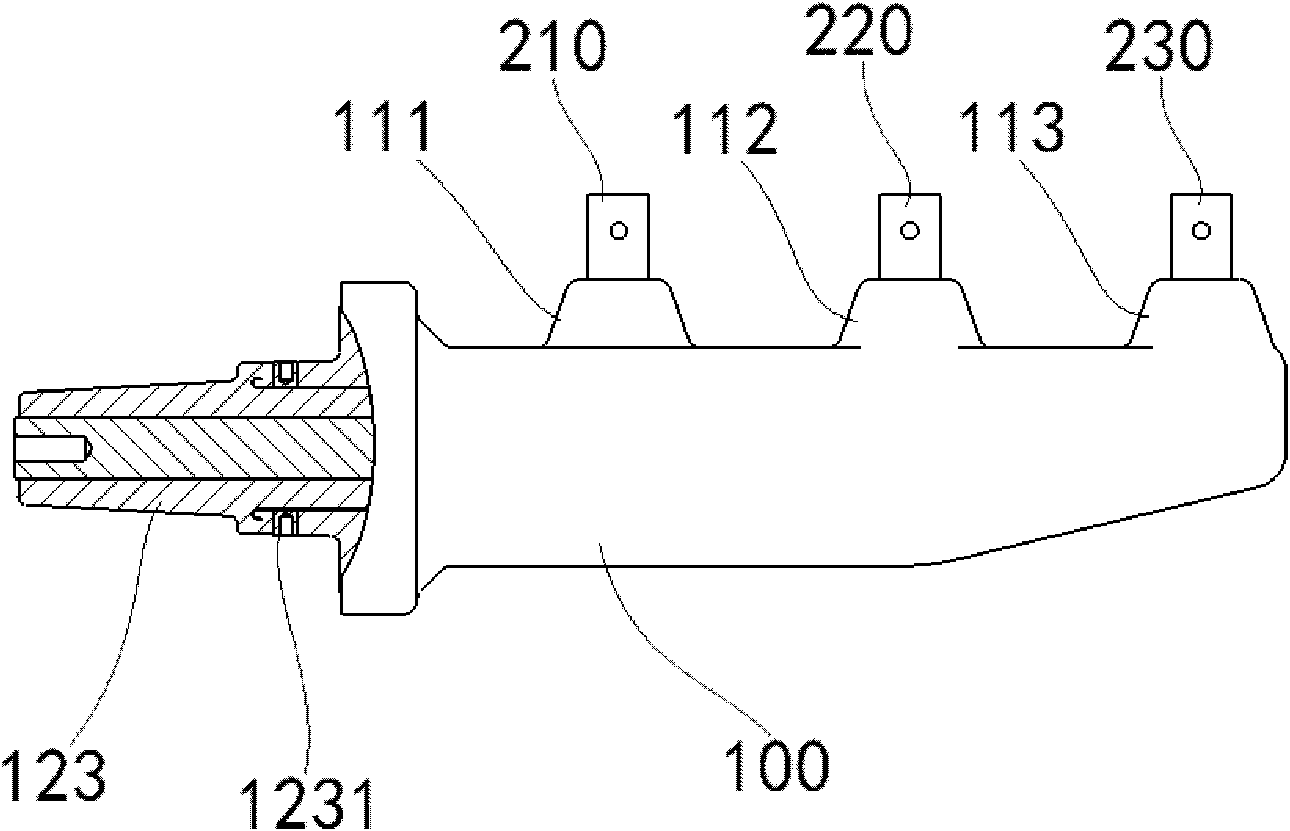

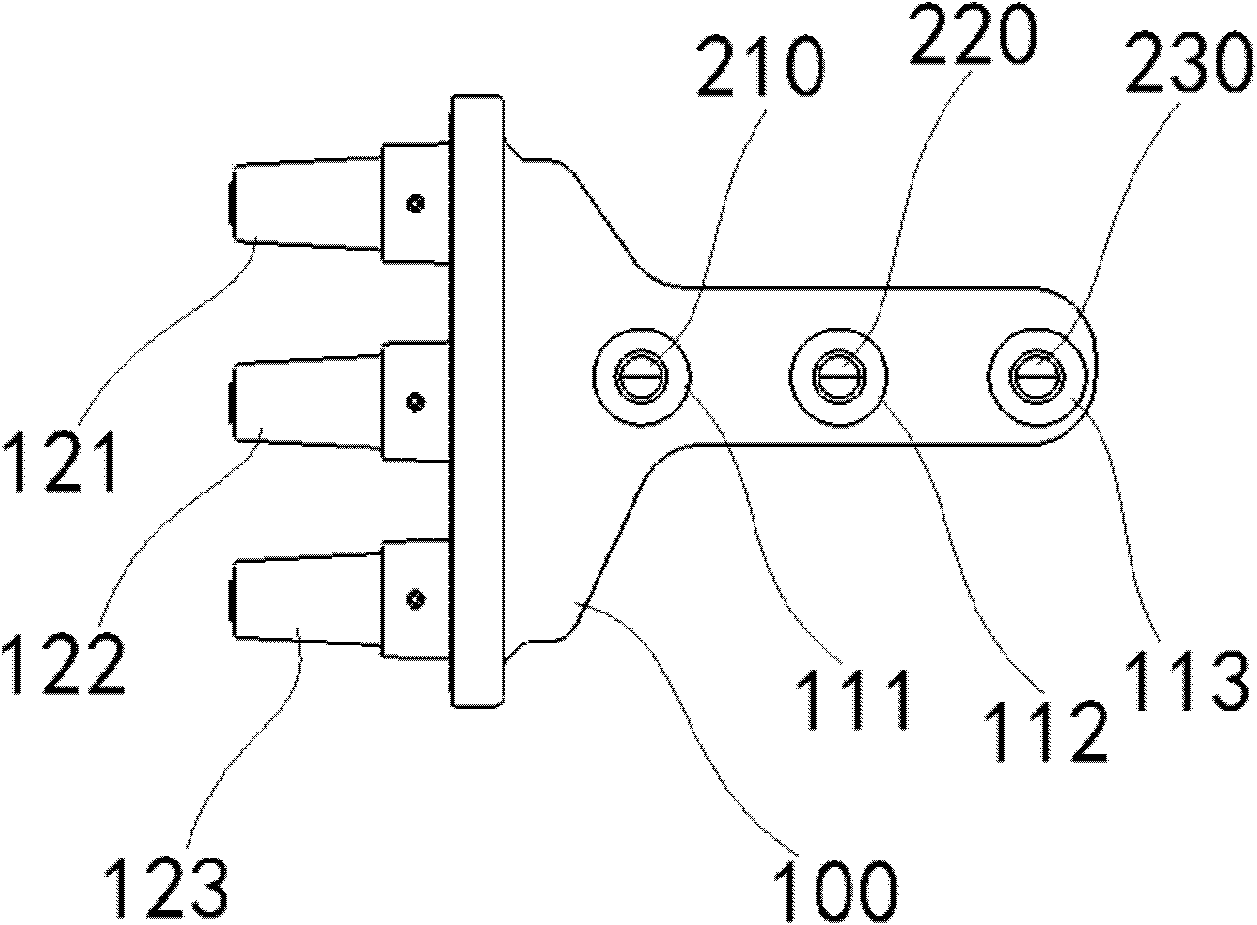

[0015] Such as figure 1 , figure 2 As shown, the present invention proposes an integrated cable inlet and outlet bushing, which includes an insulating bushing body 100 made of epoxy resin material. Three-phase busbars are arranged in the bushing body 100, which are A-phase busbars 230 and B-phase busbars respectively. The phase busbar 220, the C-phase busbar 210, and the three-phase busbar are poured into the bushing body at the same time, and the bushing body is provided with an inlet 111, an inlet 112, an inlet 113, an outlet 121, and an outlet 122 , Outlet 123, the inner end of the three-phase bus protrudes from the inlet, and the outer end protrudes from the outlet. When installing and using, the inner ends are respectively connected to the main circuit bus bars of each phase in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com