Connecting hardware fitting for sectional composite insulator

A technology of composite insulators and connecting fittings, applied in insulators, electrical components, circuits, etc., can solve the problems of inflexible freedom of fittings at both ends, increase the cost and difficulty of on-site construction, and extend the length of composite insulators. The effect of firmness, safe and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

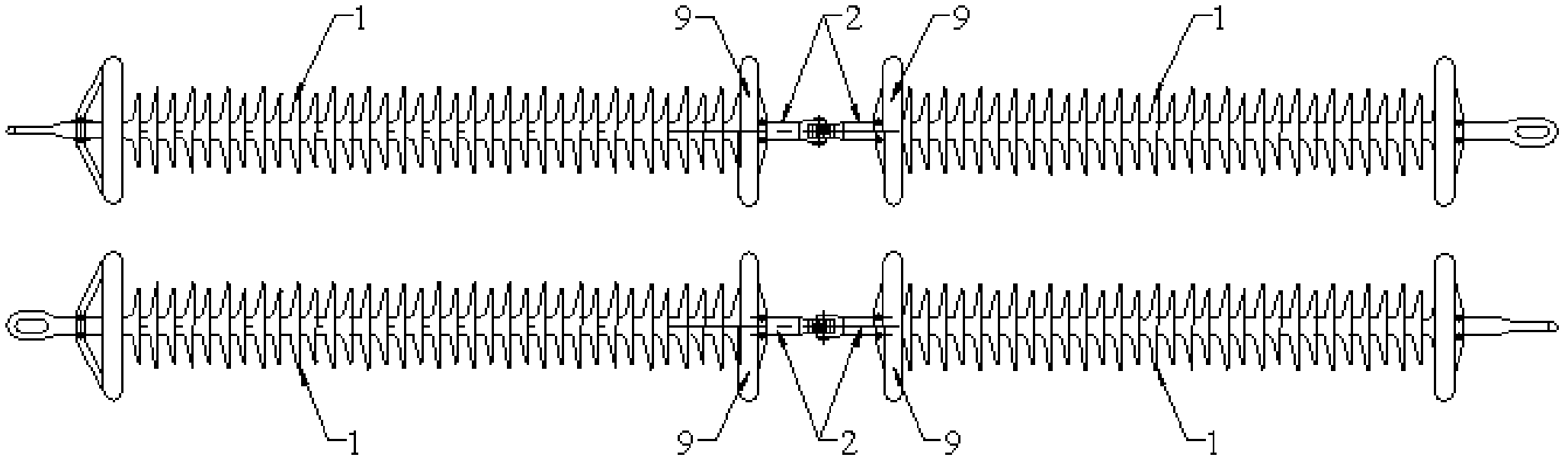

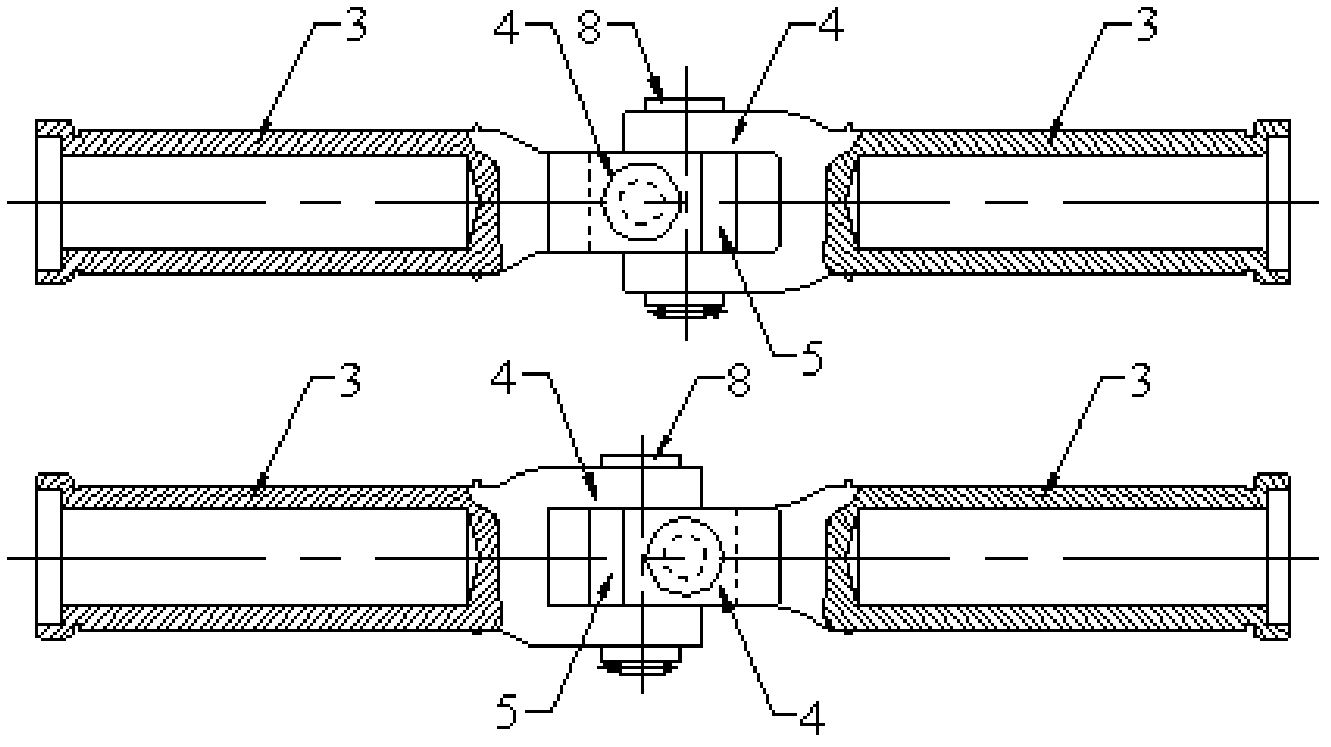

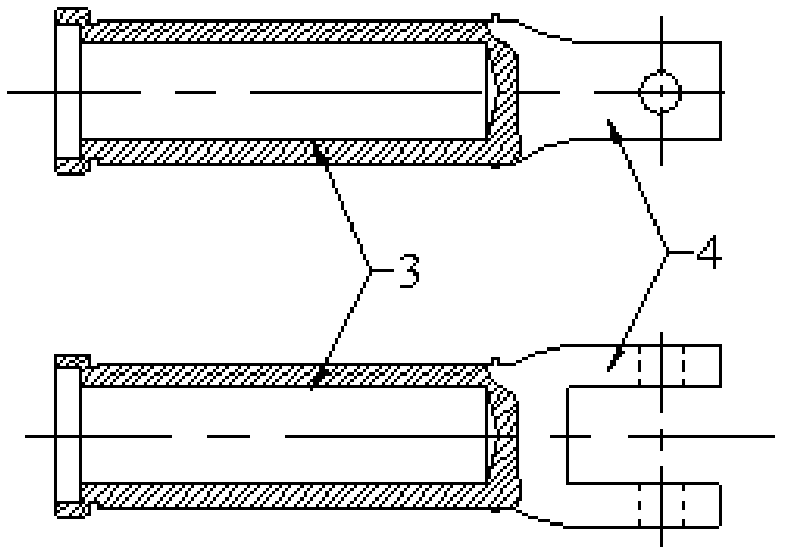

[0026] figure 1 It shows a schematic diagram of the assembly of the connecting hardware of the present invention, wherein the upper figure is a front view after assembly, and the lower figure is a top view after assembly. For the convenience of transportation, the composite insulator 1 that is too long is divided into two sections, and the composite insulator 1 after the two sections is fixed through the connecting fittings of the present invention when it is installed and used on the transmission line. In this example, two groove-type terminal fittings can swing in the horizontal and vertical directions respectively, that is, a structure in which two groove-type terminal fittings 2 arranged at 90 degrees are connected by a connecting block 5 with horizontal and vertical connection holes, Since the groove structures of the two groove-type terminal fittings 2 are directly connected to the horizontal and vertical connection holes of the connecting block 5, the two groove-type te...

Embodiment 2

[0034] The structure and working principle of the connecting fittings in this example are basically the same as those in Example 1, except that:

[0035] In this example, by adding an I-shaped connecting piece 10 between the two groove-shaped terminal fittings 2, the two groove-shaped terminal fittings can both swing in one plane. Such as Figure 6As shown, the connecting fittings in this example include two grooved terminal fittings 2, two connecting blocks 5 and an I-shaped connecting piece 10 between the two grooved terminal fittings; Figure 7 The structure of the I-shaped connector is shown, wherein the upper figure is a front view of the I-shaped connector, and the lower figure is a top view of the I-shaped connector. The two ends of the I-shaped connector 10 are respectively used to accommodate the connecting block 5 and The inner grooves 11 connected with the two grooved terminal fittings 2 are provided with installation holes in the same direction connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com