Disc-type stalk cutting test device and test method thereof

A test device and disc-type technology are applied in the disc-type stalk cutting test device and field to achieve the effects of simple and reasonable device and stable and reliable operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

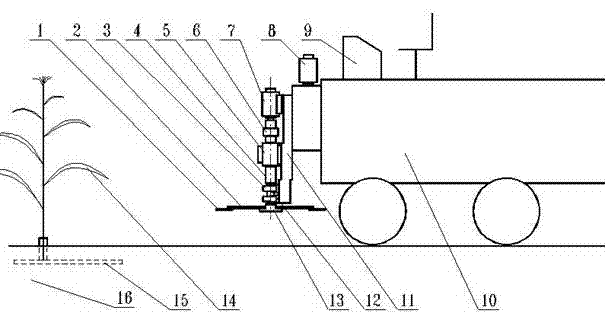

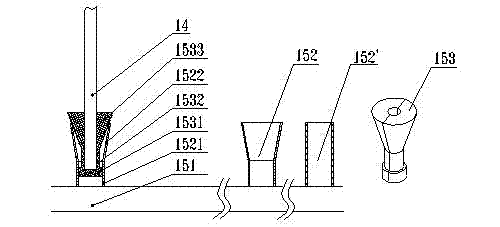

[0018] Such as figure 1 Shown is the structural diagram of the test device, including the disc cutting and measuring device (composed of 1-7, 11, 12, 13), walking trolley 10, cutting height adjustment motor 8, central console 9 and stem clamp holding device 15.

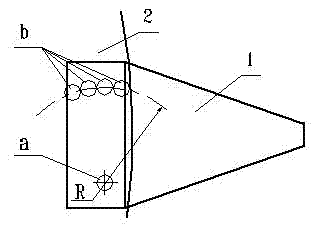

[0019] Such as figure 1 , 2 As shown, the disc cutting measuring device includes a blade 1, a cutterhead 2, a spoke disk 13, a cutterhead shaft 12, a bearing seat 3, a coupling A4, a torque speed sensor 5, a coupling B6, a drive motor 7 and Cut standoff 11. The blade 1 is connected to the cutter head 2 by bolts or rivets. There is a hole a on the cutter head 2. The position of the hole a is fixed. There are multiple holes b on the cutter head 2. The position of the hole a on the cutter head is fixed. There are many holes b There are several different locations to choose from during installation. But the center of hole b is all on the circle with the center of hole a as the center, and the distance between the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com