Alignment loading device used for stretching test of nanoscale, micron-size thin film materials

A thin film material, tensile testing technology, used in measuring devices, analyzing materials, using stable tension/pressure to test the strength of materials, etc. Structural space size, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

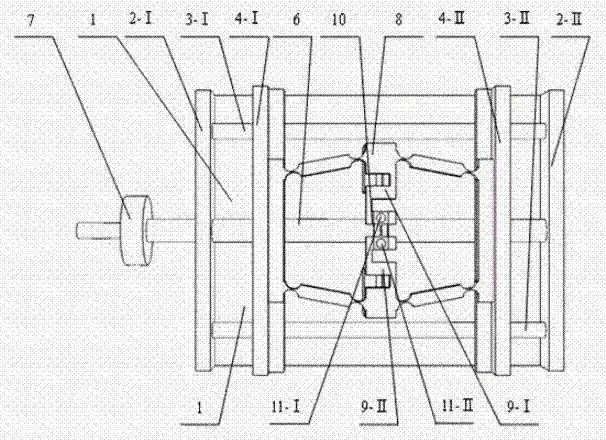

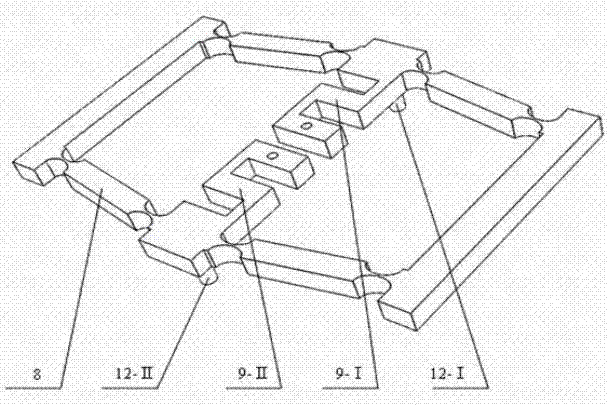

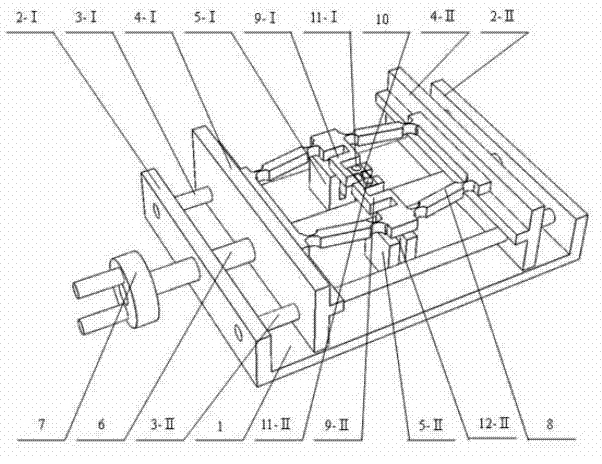

[0023] A centering loading device for tensile testing of nano- and micron-scale film materials, consisting of a reverse thread centering loading frame and a compliant hinge loading sensing component; the reverse thread centering loading frame includes a bottom plate 1, two vertical Plates 2-I, 2-II, two guide rods 3-I, 3-II, two slide plates 4-I, 4-II, two guide groove blocks 5-I, 5-II, adjusting screw 6 and Handwheel 7, two vertical plates 2-I, 2-II and bottom plate 1 are fixed to form a concave frame, two vertical plates 2-I, 2-II are respectively provided with a center hole and bearings, and two guide rods 3 -I and 3-II are located on both sides of the concave frame and are respectively fixed to two vertical plates 2-I and 2-II, and the two sliding plates 4-I and 4-II are both in the shape of a "T" and are set opposite to each other. 4-Ⅰ, 4-Ⅱ are provided with two circular holes and a central screw hole, the two circular holes are slidingly matched with the two guide rods 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com