Integral type sealing box for reciprocating type plunger pump

A kind of integral and sealed box technology, which is applied in variable displacement pump components, pump components, liquid fuel engines, etc., to achieve the effects of compact and convenient structure, easy control of assembly precision, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

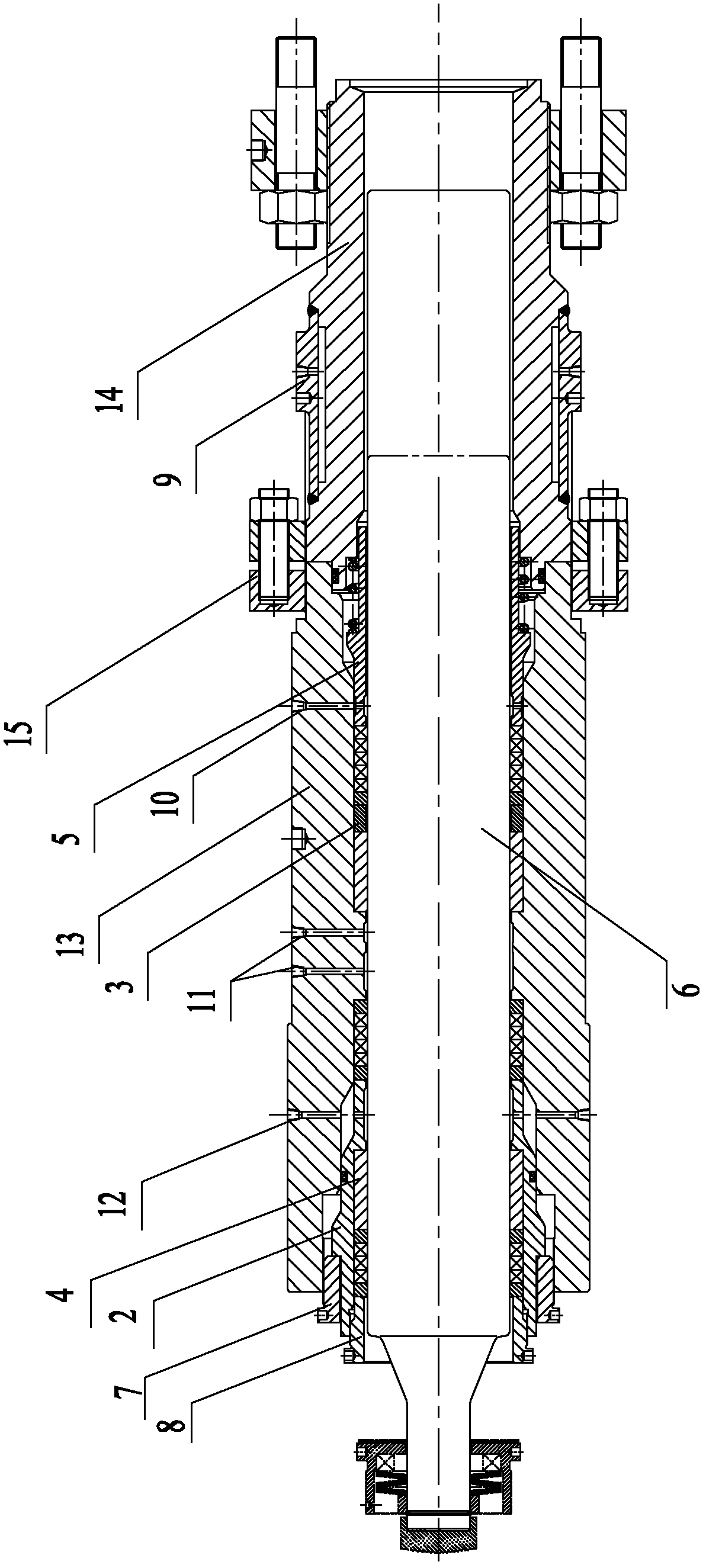

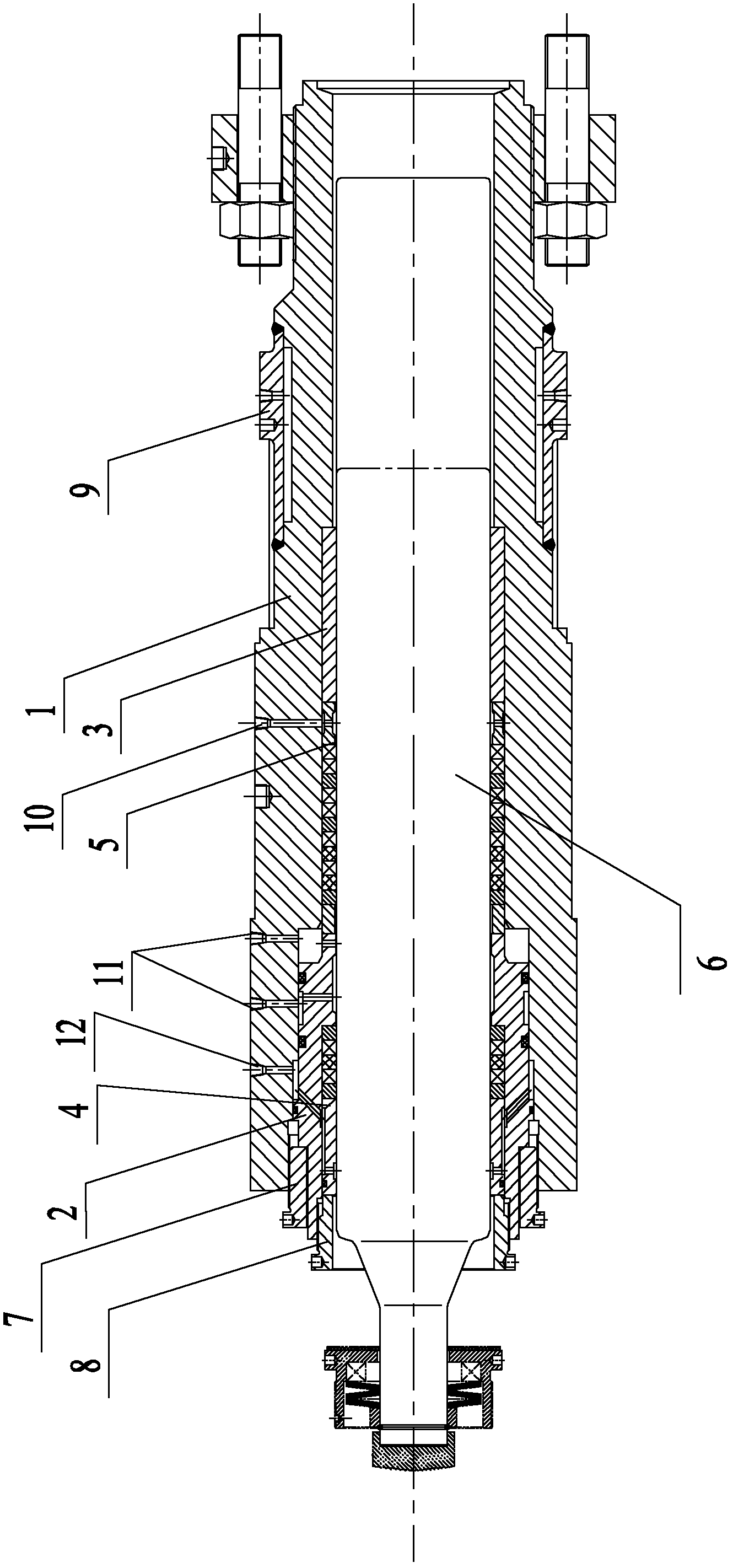

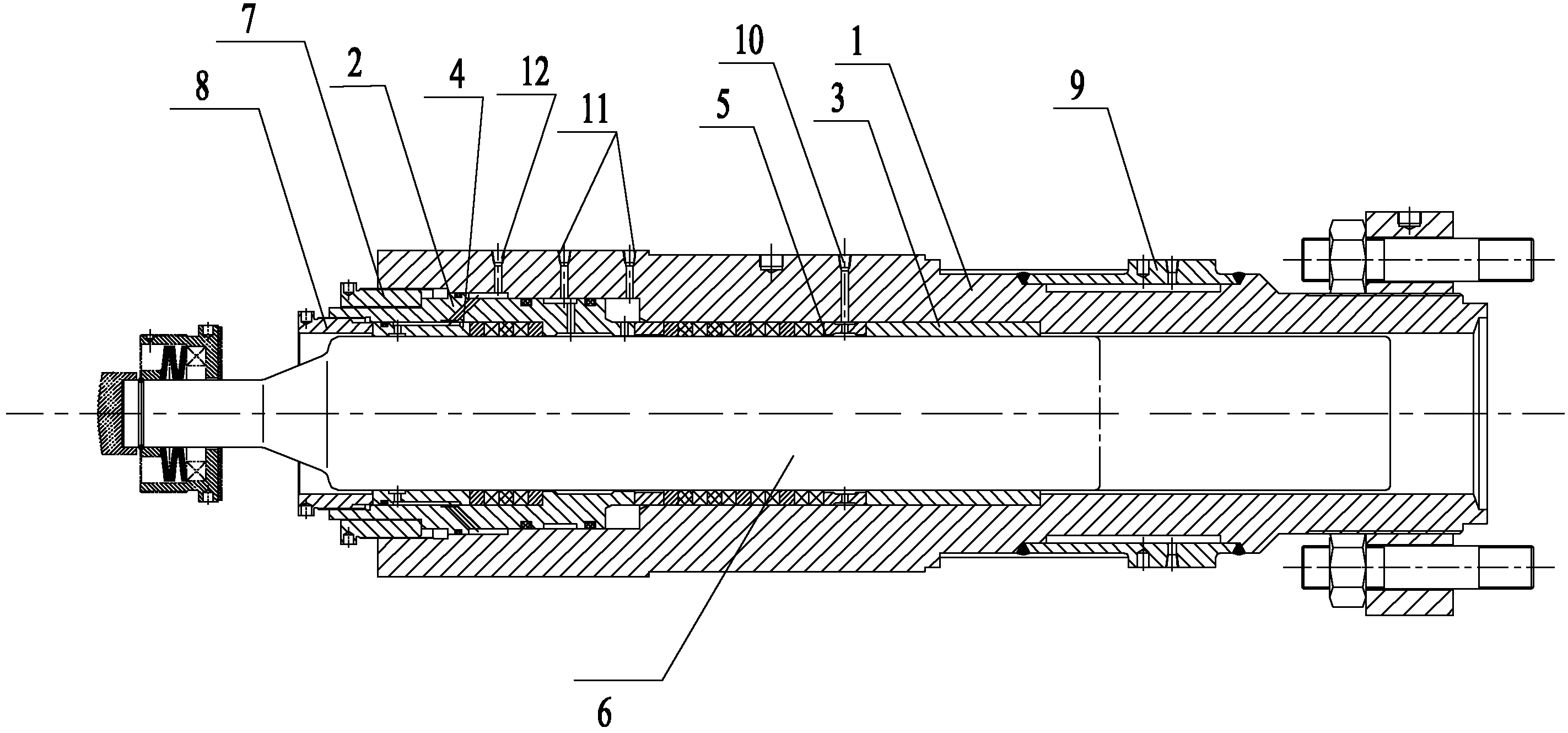

[0030] Such as figure 2 As shown, a kind of integral sealing letter for reciprocating plunger pump is sleeved on the plunger 6, and the integral sealing letter includes the plunger 6, the main sealing box body 1, the auxiliary sealing box body 2, the front guide sleeve 3. The rear guide sleeve 4, the injection sleeve 5, etc., the main sealing body 1 is an integral sealing body, the auxiliary sealing body 2, the front guide sleeve 3, the rear guide sleeve 4 and the injection sleeve 5 are all It is arranged between the main sealing box body 1 and the plunger 6, the auxiliary sealing box body 2 is located at the rear end of the main sealing box body 1, and the rear guide sleeve 4 is located inside the auxiliary sealing box body 2. The front guide sleeve 3 is located in the middle of the main sealing box body 1, and the injection sleeve 5 is located between the front guide sleeve 3 and the rear guide sleeve 4, and the front guide sleeve 3 is closely connected with the injection s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com