Mechanical arm modularized joint with force position perceiving function

A technology of modular joints and sensing functions, applied in the directions of manipulators, manufacturing tools, joints, etc., can solve the problems of limiting the application of manipulators to robot system integration, heavy weight of manipulators, low integration, etc., achieving light weight, small size, Highly integrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

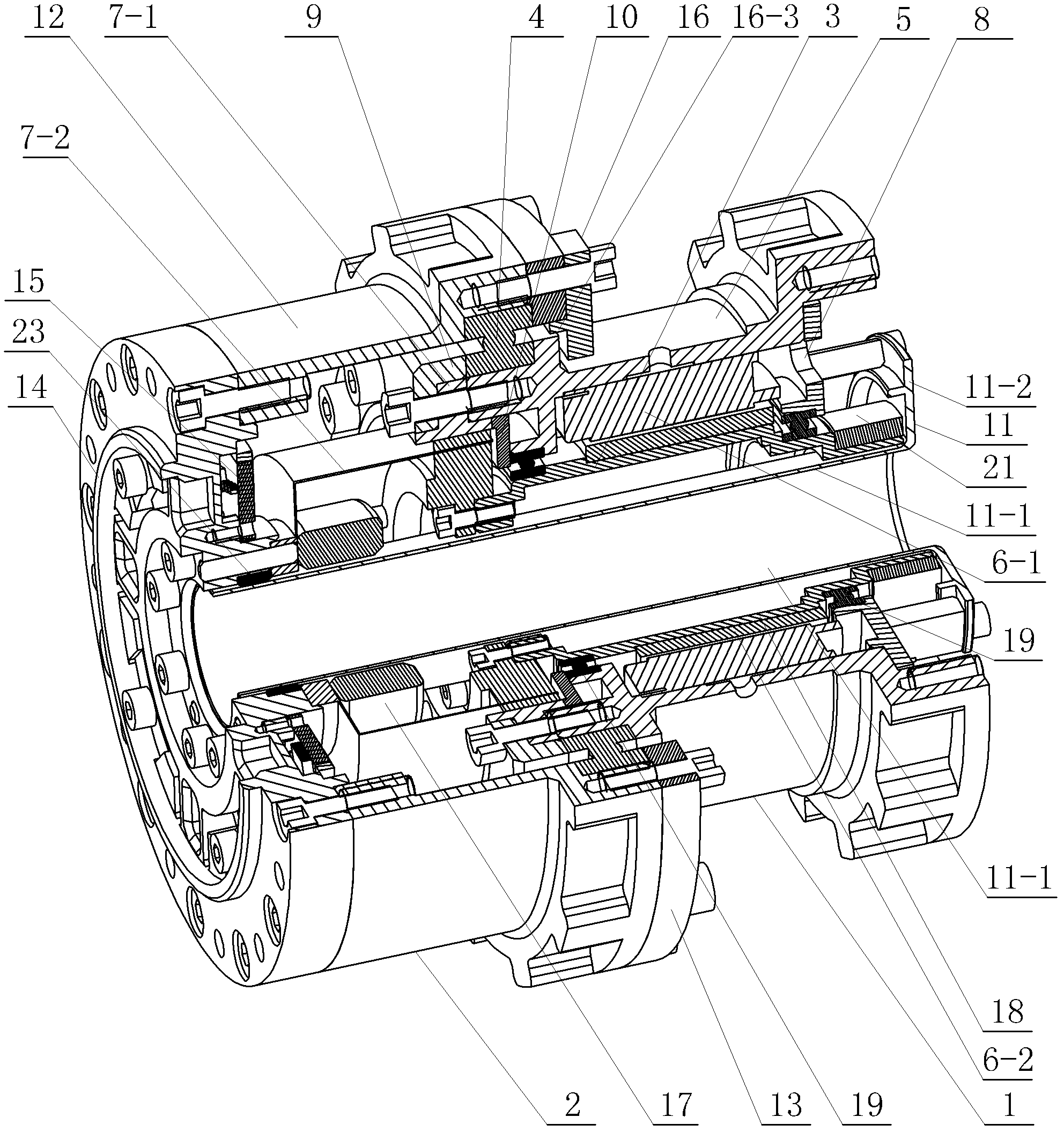

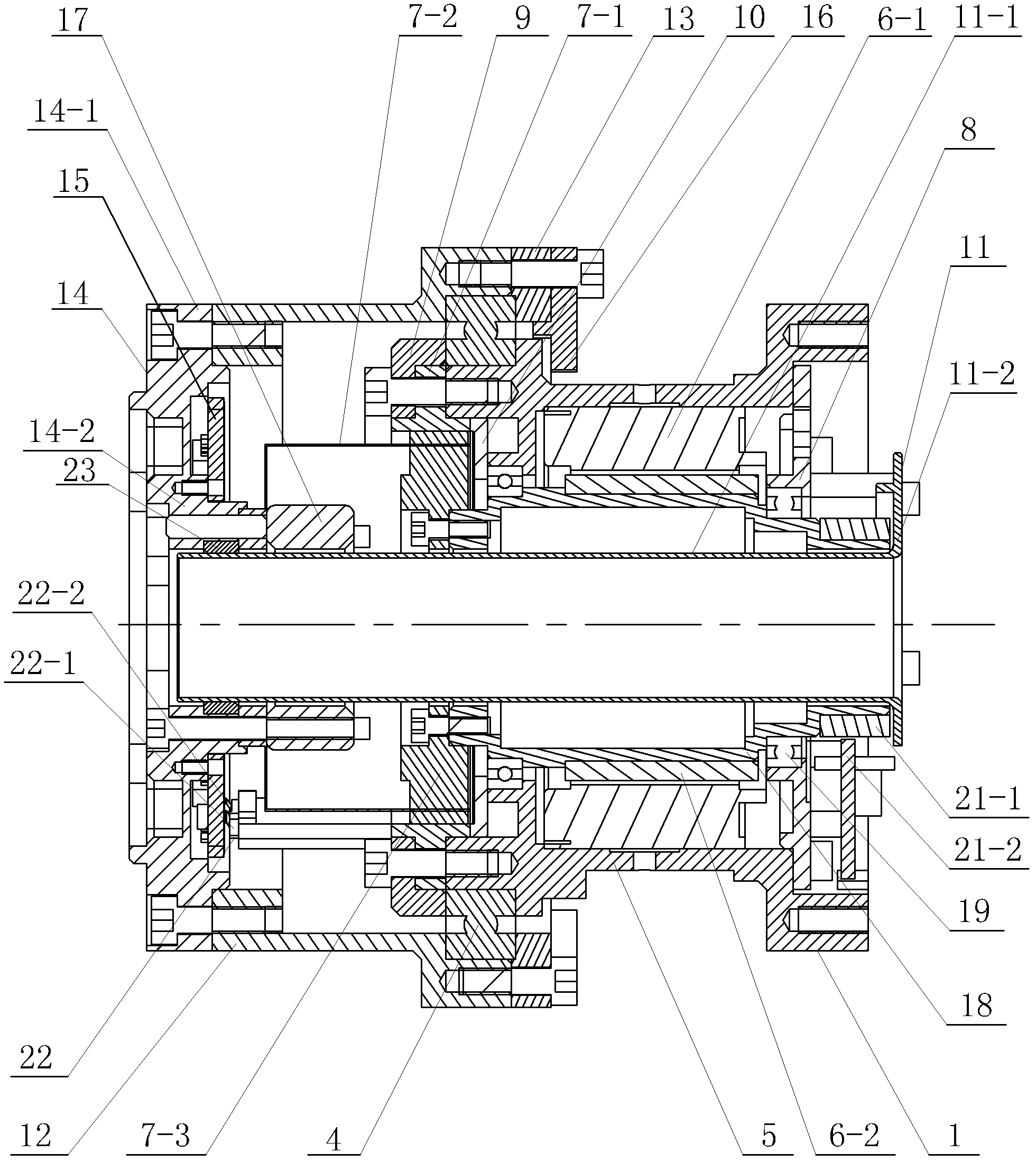

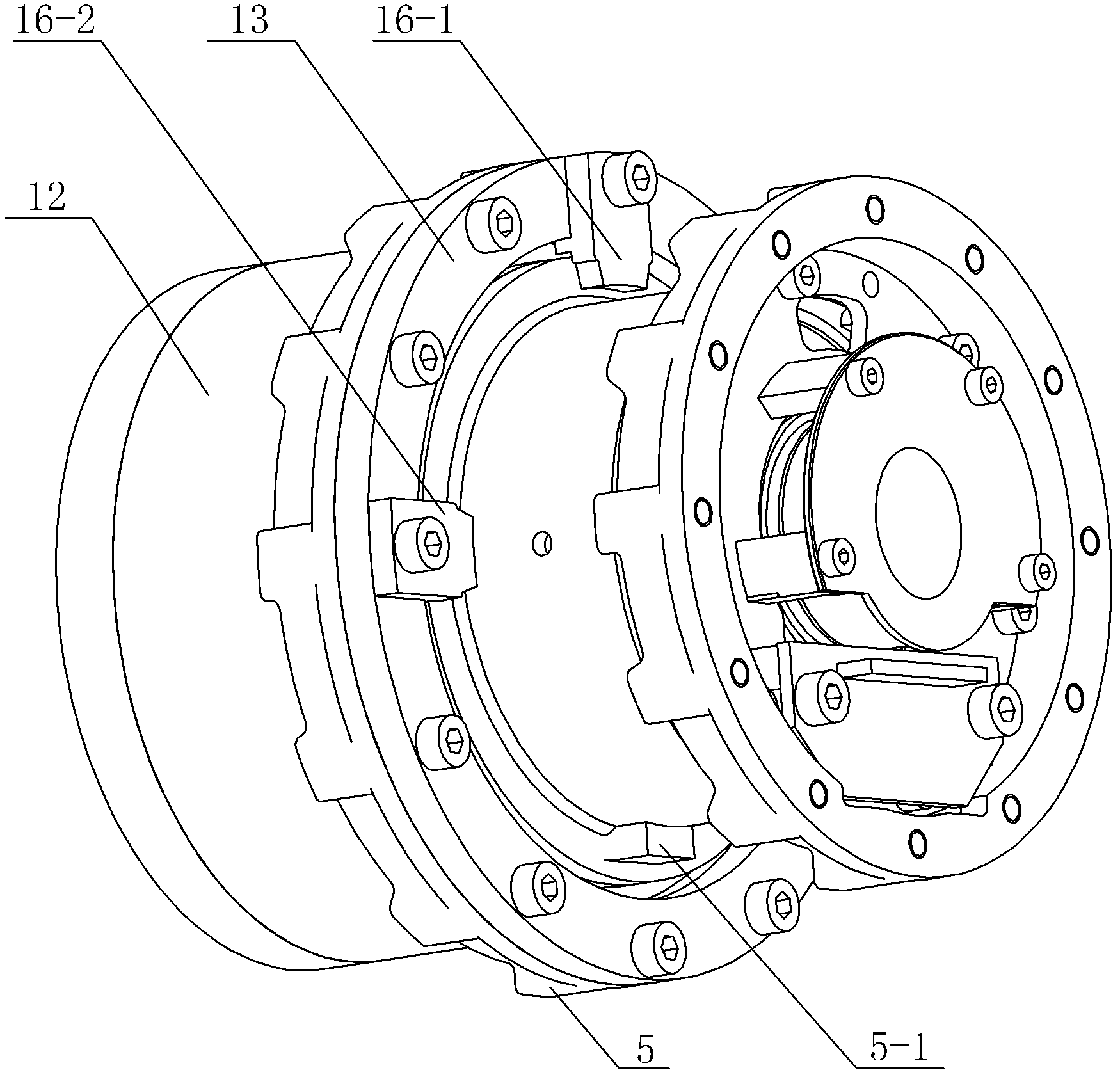

[0008] Specific implementation manner one: such as Figure 1-7 As shown, the modular mechanical arm joint with force position sensing function of this embodiment includes a joint fixing device 1, a joint output device 2, a rotating device 3, and a cross roller bearing 4; the joint is fixed The device 1 includes a fixed housing 5, a motor stator 6-1, a harmonic reducer rigid wheel 7-1, a first end cover 8, a second end cover 9, a pressure plate 10, a central hole wiring shaft 11, an insulating block 22-1 and Brush 22-2; the central hole routing shaft 11 is composed of an integrated circular tube 11-1 and a circular ring plate 11-2, one end of the circular tube 11-1 is fixedly connected to the circular ring plate 11-2; joint output device 2 Including output housing 12, third end cover 13, torque sensor 14, harmonic reducer flexible wheel 7-2, connecting nut 17, nylon support 23 and two limit stops 16, two limit stops 16 They are the first limit stop 16-1 and the second limit sto...

specific Embodiment approach 2

[0012] Specific implementation manner two: combination figure 1 , figure 2 with Figure 5 It is explained that the torque sensor 14 of this embodiment includes the torque sensor 14 including an outer ring 14-1, an inner ring 14-2, a circuit board 15, four strain beams 14-3, and four overload protection blocks 24; four strain beams 14 -3 is placed between the outer ring 14-1 and the inner ring 14-2, and the four strain beams 14-3 are evenly arranged along the circumferential direction of the outer ring 14-1 to transmit the joint output torque (the direction of the torque is along the joint Axis), an overload protection block 24 is set between two adjacent strain beams 14-3, four overload protection blocks 24 are connected to the inner ring 14-2, and each overload protection block 24 is between the outer ring 14-1 Leave a gap (make the strain beam 14-3 work in the elastic strain range, avoiding the strain beam 14-3 from being damaged due to output torque overload or impact), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com