Inflator with means for increasing the output flow of pressurized gas

A technology of pressurized gas and output flow, which is applied in transportation and packaging, pedestrian/passenger safety arrangement, vehicle safety arrangement, etc., and can solve problems such as delay in opening, time for function realization, failure of suppression function, excessive stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

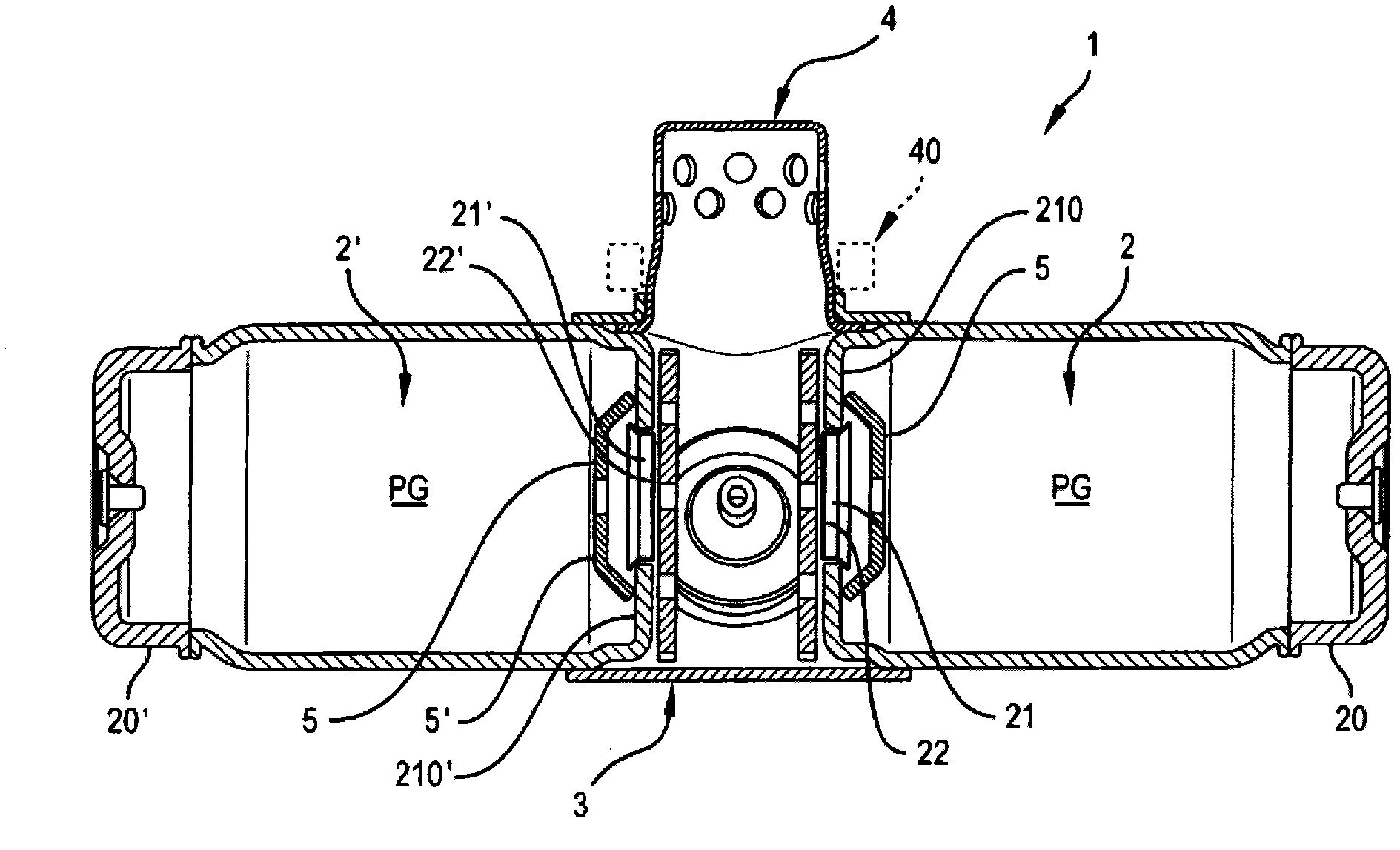

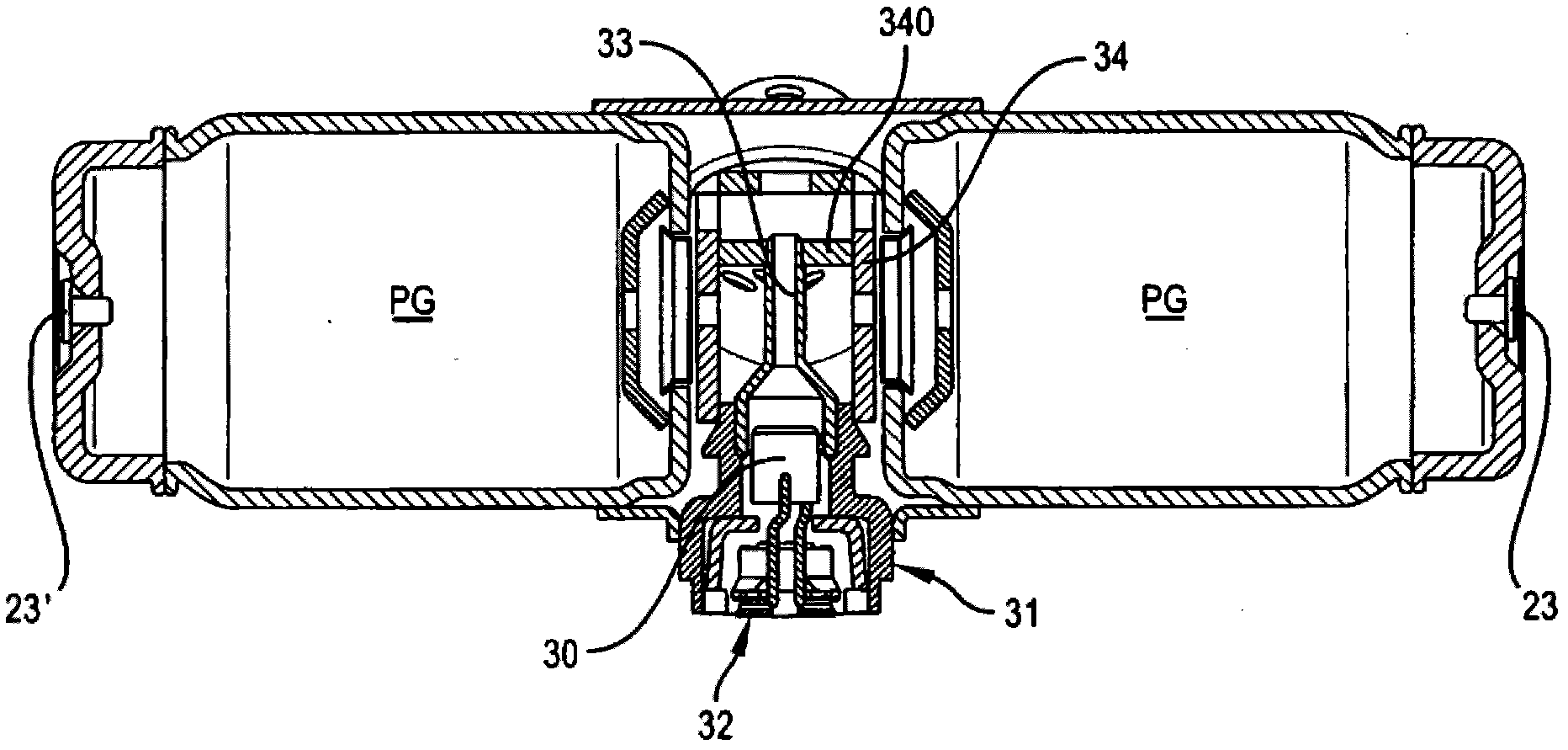

[0039] exist figure 1 and 2 The inflator 1 shown above has a known construction. The inflator 1 comprises a central housing 3 provided with an electrically activated igniter 30 mounted on a holder 31 and equipped with a shunt ring 32 .

[0040] In the chamber defined by this housing, and more precisely on the igniter, a piston 33 is mounted. The function of the piston 33 will be explained below.

[0041] The housing 3 communicates with a diffuser 4 which may be equipped with a sealing ring 40 .

[0042] Two cylindrical pressure vessels or gas chambers 2 and 2' are mounted on the casing 3. Containers 2 and 2' are adapted to receive gas under pressure PG. One of the opposite ends of the containers 2 and 2' is closed by an end cap 20 / 20' equipped with a plug 23 / 23'.

[0043] The wall 210 / 210' of the second end of the containers 2 and 2' has a hole 21 / 21' which is normally closed by a foil 22 / 22' on the outside of the container and fixed to the wall 210 / 210' . This fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com