On-line distributed hydraulic station oil tank centralized oil replenishment system and oil replenishment method

A technology of hydraulic station and oil tank, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc. It can solve the problems of production impact, high fire safety requirements, and large investment, so as to reduce recovery time and reduce The labor intensity of employees and the effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

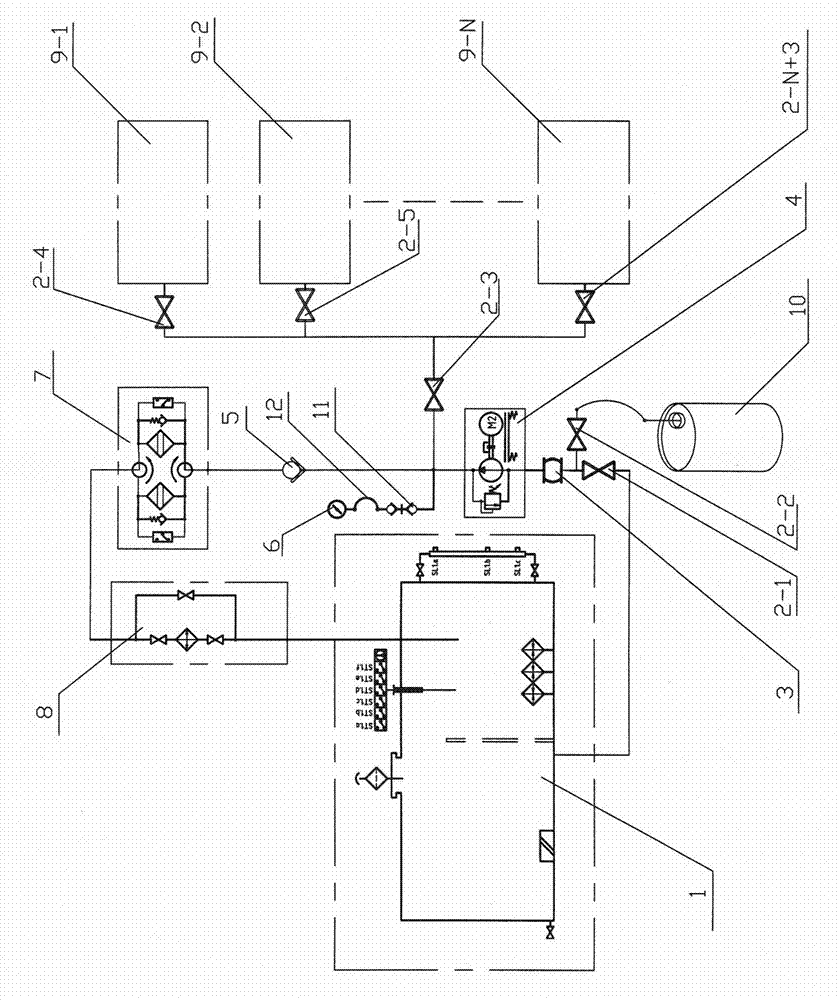

[0027] Embodiment 1. An online dispersed hydraulic station oil tank centralized oil supply system, which consists of an online large hydraulic station oil tank 1, a plurality of ball valves 2-1~2-N+3, shock absorber throat 3, screw pump motor unit 4, single It consists of a valve 5, a pressure gauge 6, a filter device 7, a cooling device 8, a spare oil barrel 10, a pressure measuring joint 11, and a pressure measuring hose 12.

[0028] The oil tank 1 of the online large hydraulic station is connected to the first ball valve 2-1 through a pipeline, the other end of the first ball valve 2-1 is connected to the shock absorber throat 3 through a pipeline, and the other end of the shock absorber throat 3 is connected to the screw pump motor unit 4 through a pipeline connection, the other end of the screw pump motor unit 4 is connected to the one-way valve 5 through a pipeline, the other end of the one-way valve 5 is connected to the filter device 7 through a pipeline, and the other ...

Embodiment 2

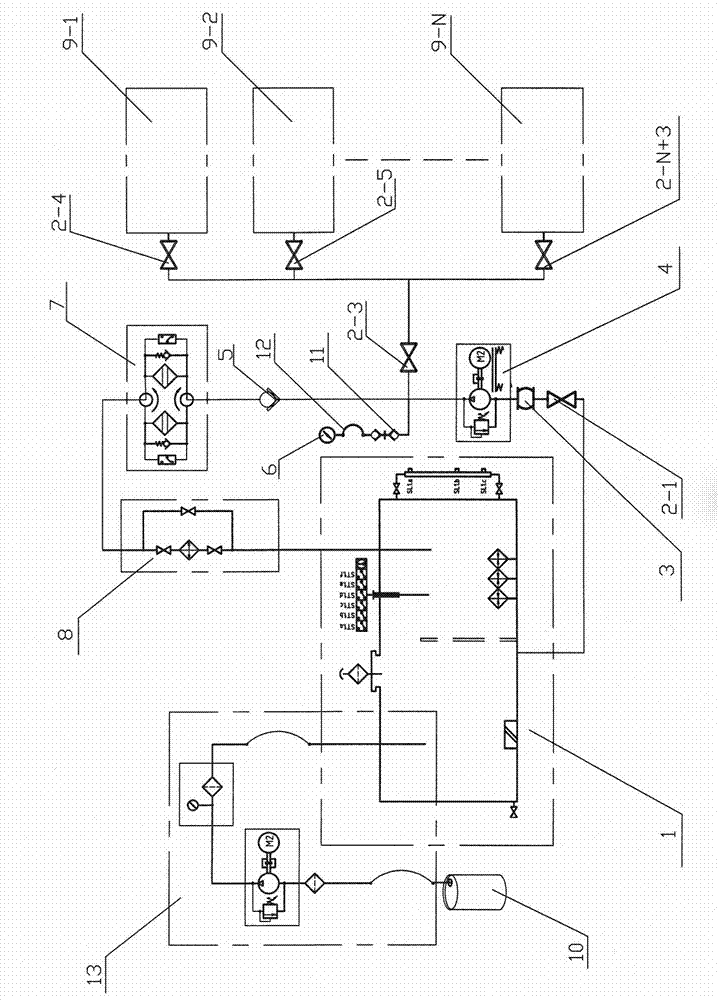

[0032] Embodiment 2: A refueling trolley 13 is fixed on the side of the online large hydraulic station fuel tank 1 of the online large hydraulic station fuel tank centralized oil supply system, and the spare oil barrel 10 is connected to the oil inlet pipe of the refueling trolley 13 through an oil suction hose, and the refueling trolley The drain pipe of 13 is connected in the oil tank 1 of the online large hydraulic station.

[0033] The specific operation steps for refueling the online large hydraulic station fuel tank 1 and the online decentralized hydraulic station fuel tanks 9-1~9-N of the online decentralized hydraulic station fuel tank centralized oil replenishment system through the refueling trolley 13 are as follows:

[0034]1. When replenishing the oil tank 1 of the online large hydraulic station, the ball valves 2-4~2-N+3 connected to the oil tanks 9-1~9-N of each online distributed hydraulic station are in a normally closed state and will be connected to the refue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com