Internal spiral nozzle with diversion trench

An internal helix and diversion groove technology, used in construction and other directions, can solve the problems of sand carrying, cooling, poor lubrication, etc., and achieve the effect of good tooth protection, increased fluid velocity, and prevention of wire withdrawal and tripping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

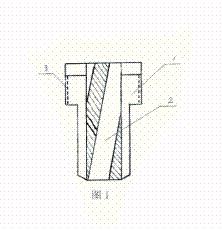

[0032] figure 1 It is a schematic structural diagram of the main view of the inner spiral nozzle with two spiral diversion grooves 2;

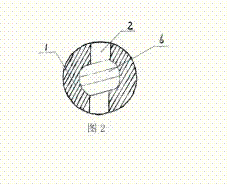

[0033] figure 2 for figure 1 Schematic diagram of the top view structure.

[0034] One end surface of the inner spiral nozzle body 1 is provided with a wrench fastening groove 6 .

[0035] The inner spiral nozzle body is a hard alloy inner spiral nozzle.

[0036] Figure 9 Shown is a schematic diagram of the main view of the drill bit, and multiple horizontal inner spiral nozzles are installed on the side of the drill bit.

[0037] Figure 10 for Figure 9 Looking up at the schematic diagram of the structure, internal spiral nozzles 1 of different sizes are installed in the spiral groove on the bottom surface of the drill bit.

[0038] Figure 11 for Figure 9 Another structural schematic diagram of looking up, the drill bit bottom surface spiral groove is equipped with internal spiral nozzles 1 with different sizes. This nozzle dia...

Embodiment 2

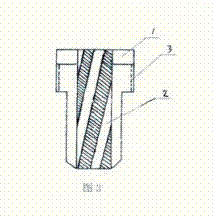

[0040] image 3 It is a schematic structural diagram of the front view of the inner spiral nozzle with three spiral guide grooves 2 .

[0041] Figure 4 for image 3 Schematic diagram of the top view structure.

[0042] One end surface of the inner spiral nozzle body 1 is provided with a wrench fastening groove 6 .

[0043] The inner spiral nozzle body is a ceramic inner spiral nozzle, and the arrangement of the nozzles is the same as that in Embodiment 1.

Embodiment 3

[0045] Figure 5 It is a schematic structural diagram of the front view of the inner spiral nozzle with four spiral guide grooves 2 .

[0046] Figure 6 for Figure 5 Schematic diagram of the top view structure.

[0047] One end surface of the inner spiral nozzle body 1 is provided with a wrench fastening groove 6 .

[0048] The inner spiral nozzle body is a hard alloy or ceramic inner spiral nozzle, and the arrangement of the nozzles is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com