Printing and dyeing ink for direct inkjet textile and preparation method thereof

A textile and ink technology, applied in textiles and papermaking, dyeing, ink and other directions, can solve the problems of uncirculated, immature printing and dyeing ink, etc., and achieve the effects of good fluidity, high color fastness and smooth jetting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The method for preparing the red printing and dyeing ink of 1000kg direct-jet textiles at one time:

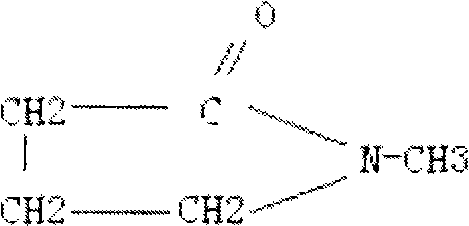

[0065] Among the above raw materials, CI reactive red 31 dye weighs 60kg, N-methyl-2 pyrrolidone weighs 40kg, ethylene glycol monoethyl ether weighs 20kg, isopropanol weighs 20kg, triethanolamine 2kg, glycerin weighs 200kg and deionized water weighed 658kg, placed in a stirring container at room temperature, stirred and mixed for 1 hour, left to stand for 12 hours, filtered with a filter, packaged, and the red printing and dyeing ink of the finished direct-jet textile was obtained.

Embodiment 2

[0067] The method for preparing the yellow printing and dyeing ink of 1000kg direct-jet textiles at one time:

[0068] Among the above raw materials, CI reactive yellow 57 dye weighs 54kg, N-methyl-2 pyrrolidone weighs 40kg, ethylene glycol monoethyl ether weighs 20kg, isopropanol weighs 20kg, triethanolamine 2kg, and glycerol weighs 220kg Weigh 644kg with deionized water, put it into a stirring container at room temperature, stir and mix for 1 hour, let it stand for 12 hours, filter with a filter, pack, and obtain the yellow printing and dyeing ink of the finished direct-jet textile.

Embodiment 3

[0070] The method for preparing the blue printing and dyeing ink of 1000kg direct-jet textiles at one time:

[0071] Among them, CI reactive blue 19 dye weighs 55kg of the above raw materials, N-methyl-2 pyrrolidone weighs 40kg, ethylene glycol monoethyl ether weighs 20kg, isopropanol weighs 2kg, glycerol weighs 220kg, triethanolamine 20kg and deionized water weighed 643kg, placed in a stirring container at room temperature, stirred and mixed for 1 hour, left to stand for 12 hours, filtered with a filter, packaged, and the blue printing and dyeing ink of the finished direct-jet textile was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com