Internal expanding type centering fixture for turning large-scale sleeve parts

A technology of centering fixtures and sleeves, used in manufacturing tools, metal processing equipment, turning equipment, etc., can solve the problems of difficult to guarantee the machining accuracy of workpieces, time-consuming and laborious, and save processing procedures and time. The effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention should not be limited thereto.

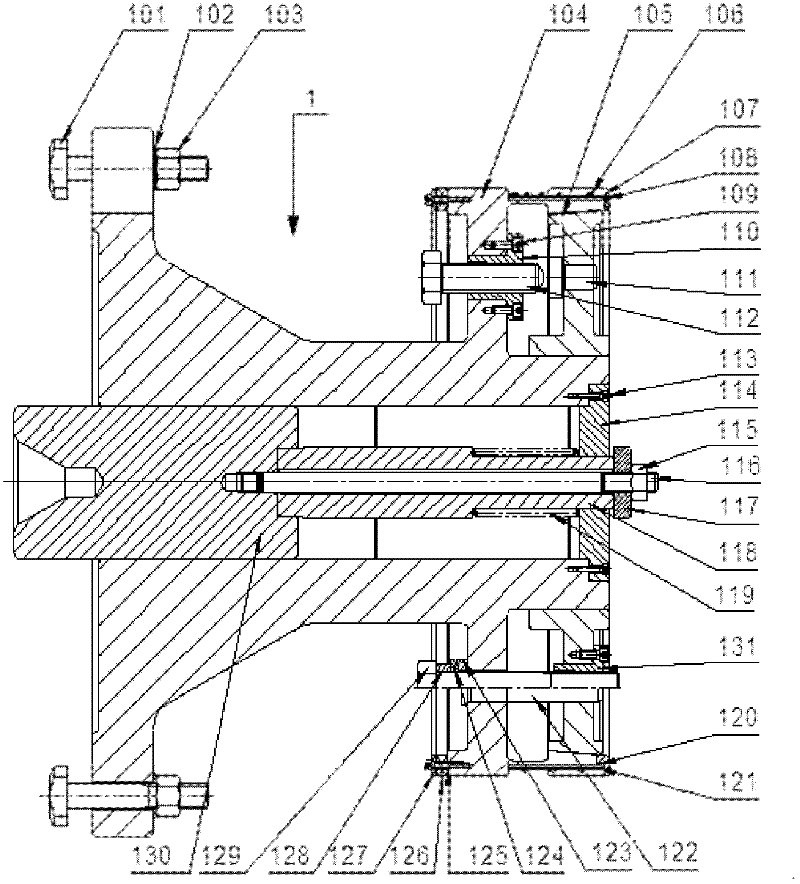

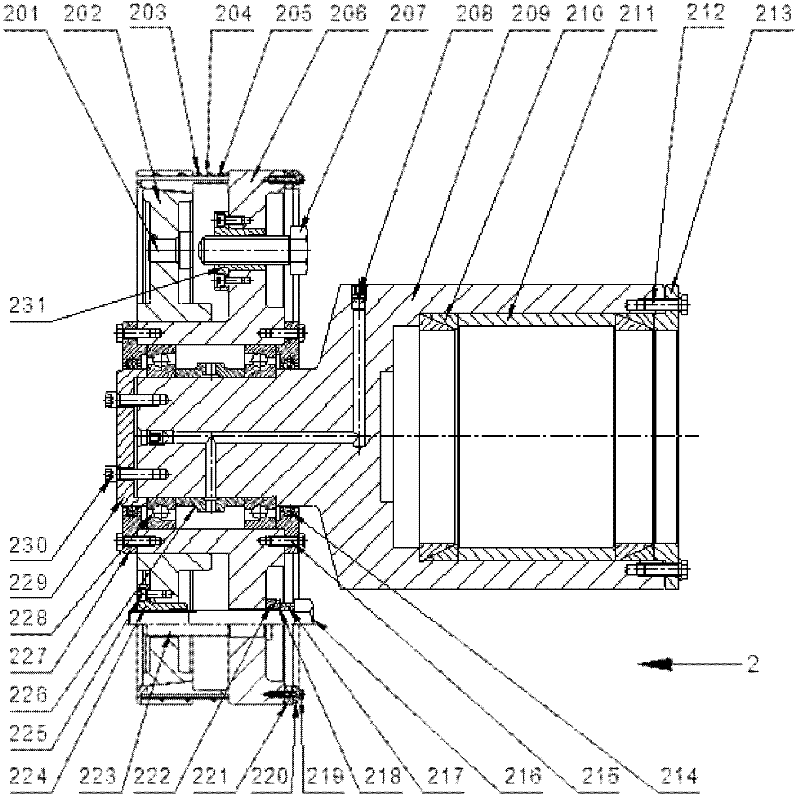

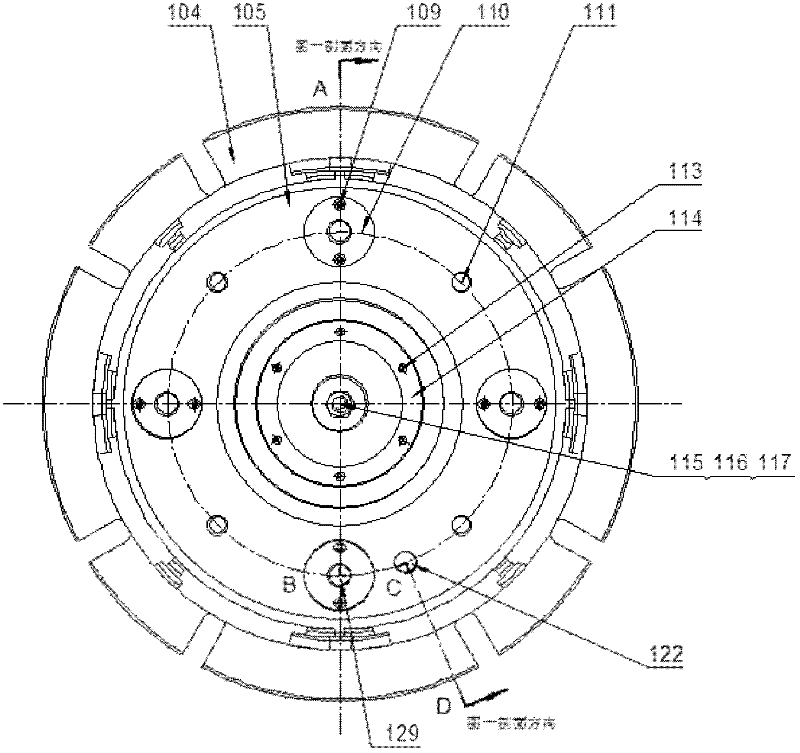

[0024] Please see first figure 1 , figure 2 and image 3 , figure 1 It is a schematic diagram of the structure of the clamping chuck clamp in the internal expansion centering clamp for machining large-scale sleeve parts of the present invention, and it is also image 3 A cross-sectional view of the ABCD in, figure 2 It is a structural schematic diagram of the tail shaft seat fixture in the internal expansion centering fixture of the large-scale sleeve parts of the car processing of the present invention, image 3 It is a side view of the clamping chuck clamp in the internal expansion centering clamp for machining large sleeve parts of the present invention. As shown in the figure, an internal expansion centering fixture for machining large sleeve parts. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com