Intermediate and far infrared two-waveband laser

A dual-band, far-infrared technology, applied in the field of lasers, can solve the problems of no infrared dual-band laser device, complex dual-band film process, and the optical axis cannot be completely overlapped, and achieve long-term continuous light output, good maneuverability, and work. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

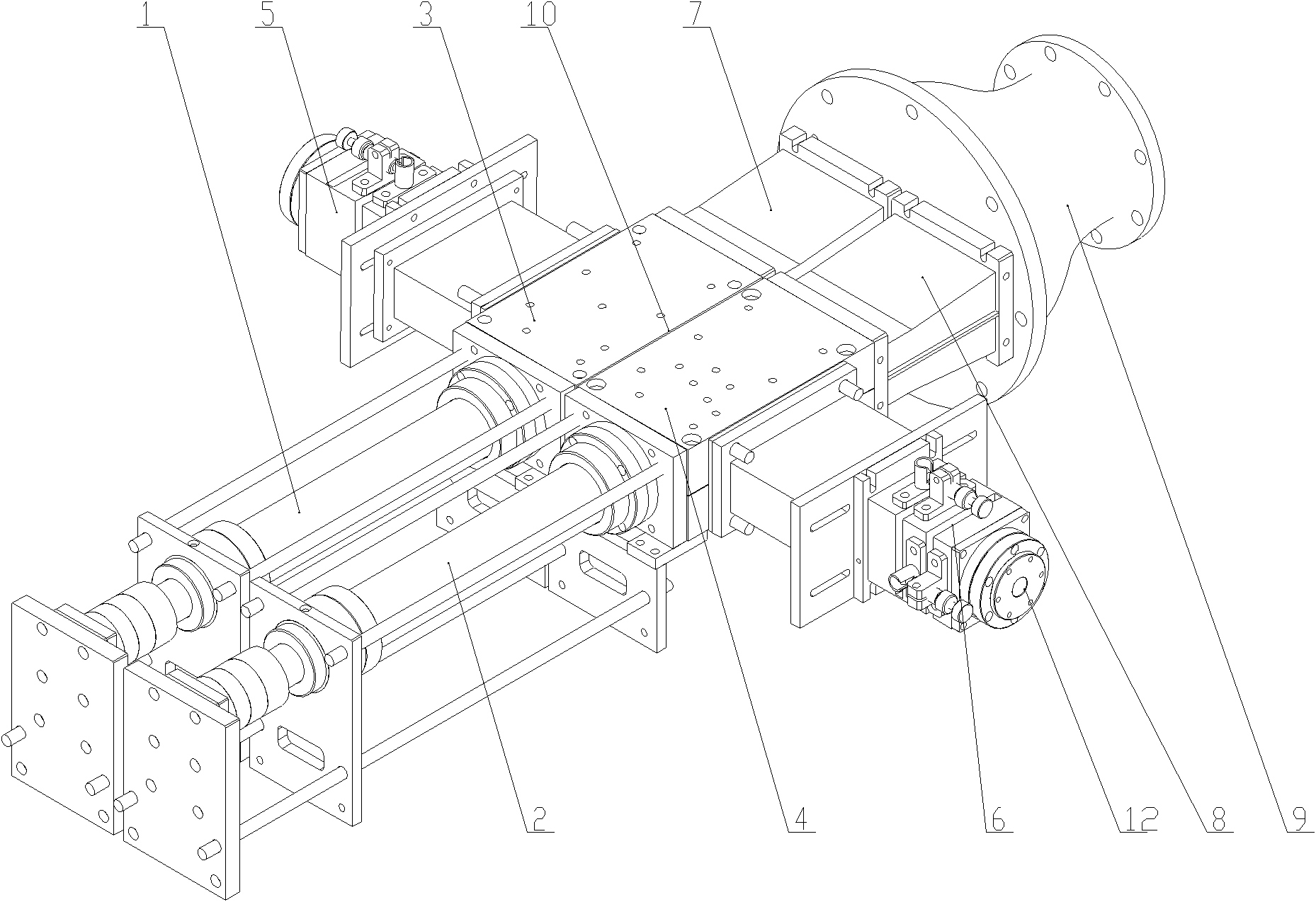

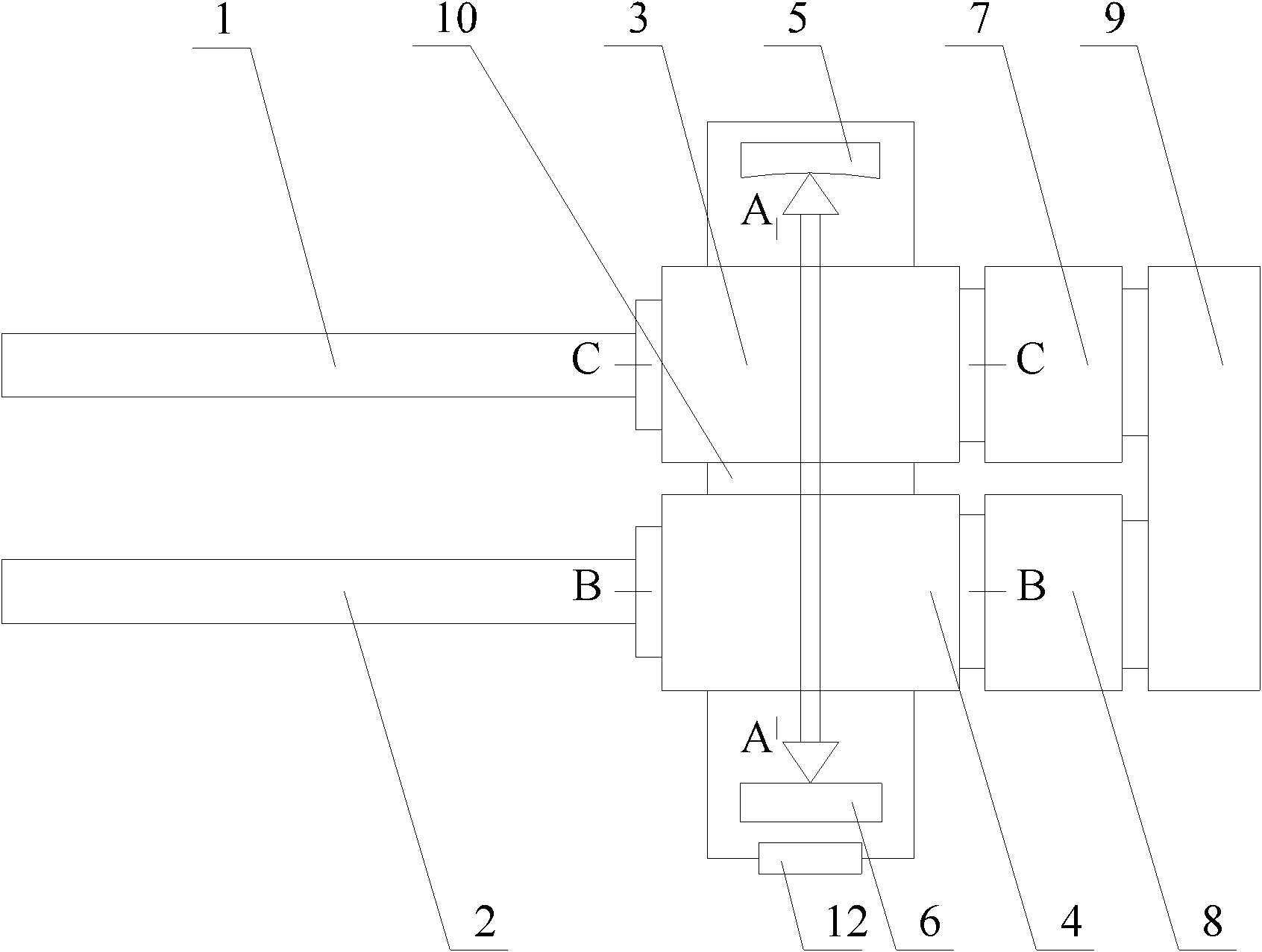

[0044] a kind of like figure 2 , image 3 The shown mid- and far-infrared dual-band laser of the present invention, the dual-band laser includes CO 2 Laser Gain Block and DF Laser Gain Block, CO 2 The laser gain block consists of sequentially connected CO 2 Laser discharge tube 2, CO 2 Laser Gain Generator 4 and CO 2 The laser heat exchange tube 8 and the DF laser gain module include the DF laser discharge tube 1, the DF laser gain generator 3 and the DF laser heat exchange tube 7 connected in sequence, and the CO 2 Both the laser heat exchange tube 8 and the DF laser heat exchange tube 7 are connected to a vacuum system 9 . The structure of the above two laser discharge tubes is exactly the same, the anode is a single nickel needle, and the discharge airflow is injected around the anode; the cathode is a nickel-plated copper ring, and the airflow direction is from the anode to the cathode.

[0045] Depend on figure 2 , image 3 It can be seen that the CO in this exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com