Rotor-type internal-compression oil-gas mixed transport pump unit

A technology for driving devices and pipelines, which is applied in reactors, greenhouse gas reduction, nuclear power generation, etc., to achieve the effects of high operation accuracy, flexible operation, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

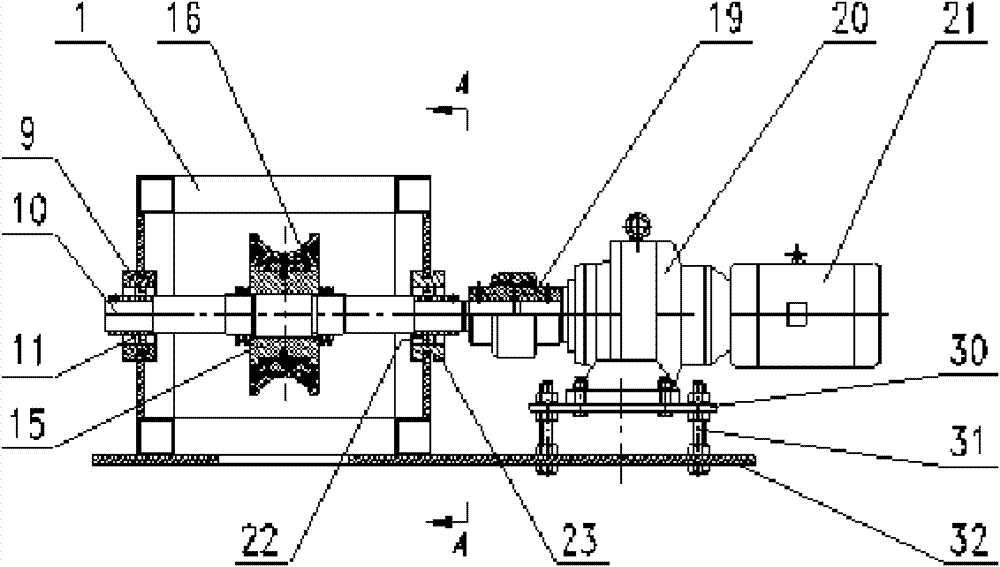

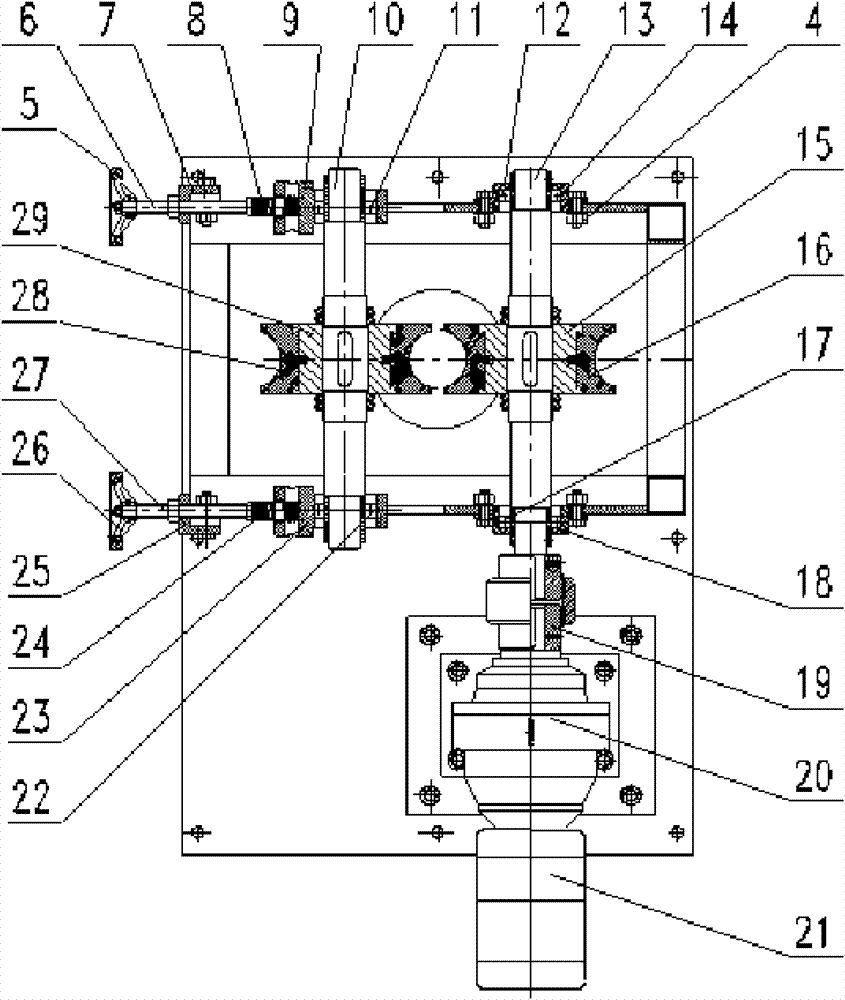

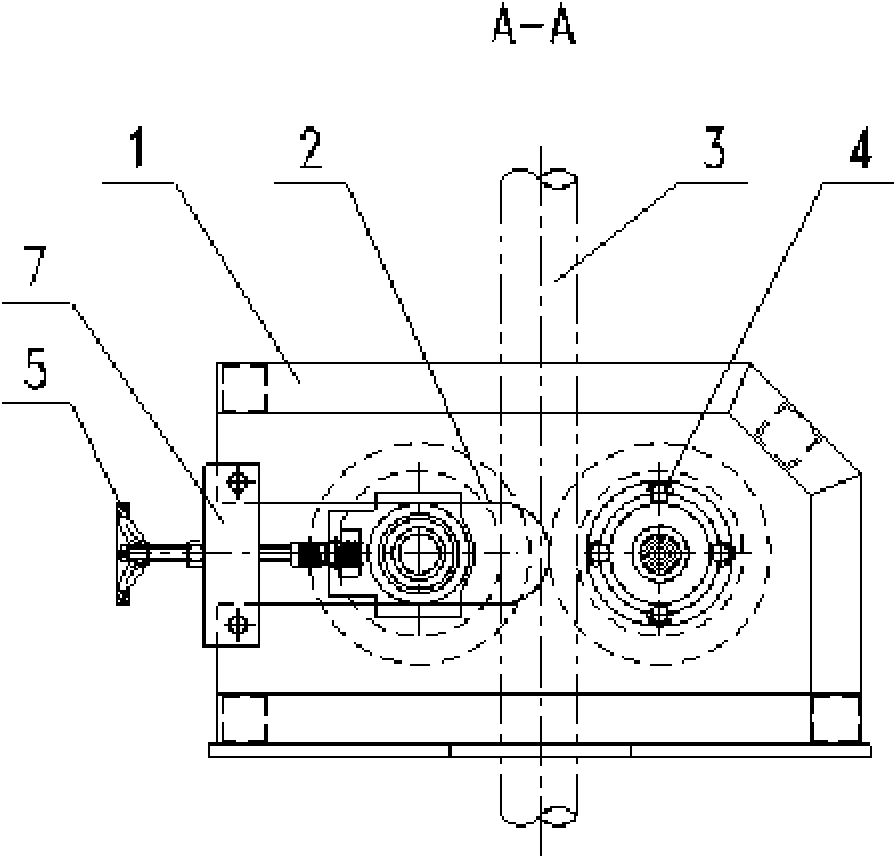

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0021] This embodiment mainly consists of frame 1, first handwheel 5, second handwheel 26, first leading screw 6, second leading screw 27, driving wheel shaft 13, driven wheel shaft 10, first drum 29, second Drum wheel 15 and the first rubber wheel 28 that viton make and the second rubber wheel 16 etc. parts constitute.

[0022] The same position of the front and rear plates on the right side of the frame 1 has a driving wheel shaft hole, the first bearing end cover 14 and the second bearing end cover 18 are fixed on the driving wheel shaft hole, the driving wheel shaft 13 passes through the driving wheel shaft hole, and passes through the second bearing 12 and the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com