Motorized valve

An electric valve and valve stem technology, which is applied to lift valves, valve devices, valve details, etc., can solve the problems of a large number of parts and troublesome manufacturing, and achieve the effect of simplifying the manufacturing process, low manufacturing cost, and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

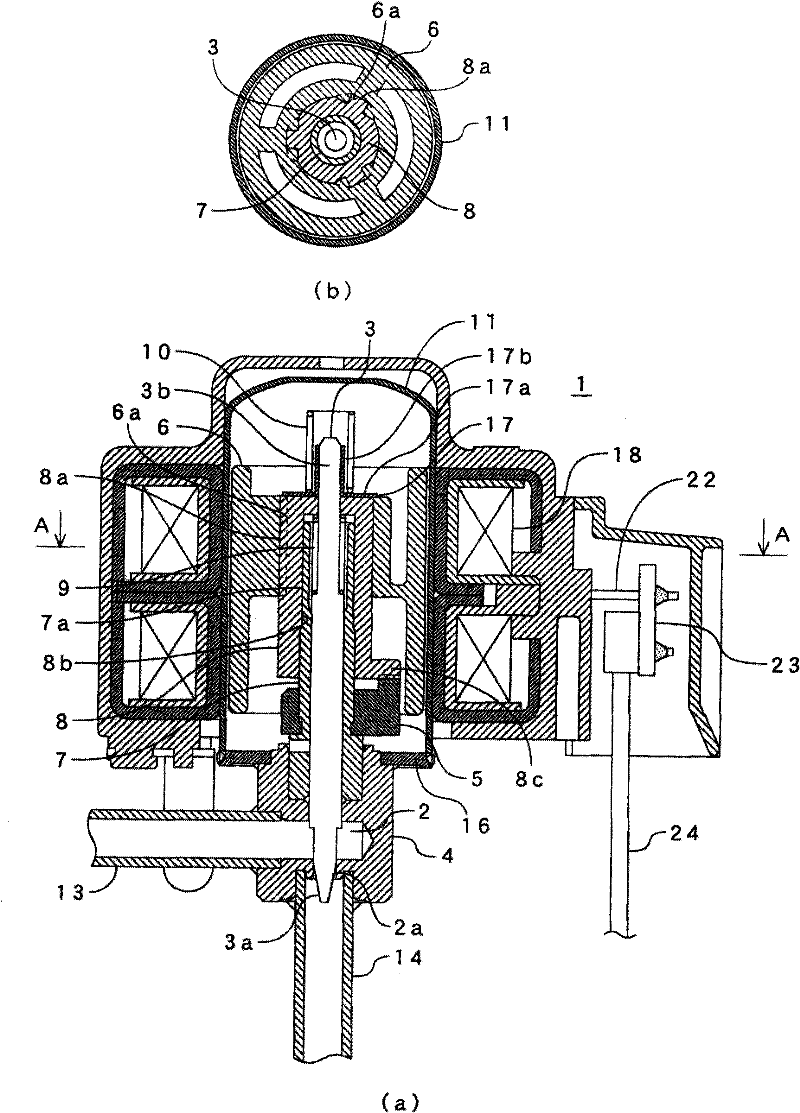

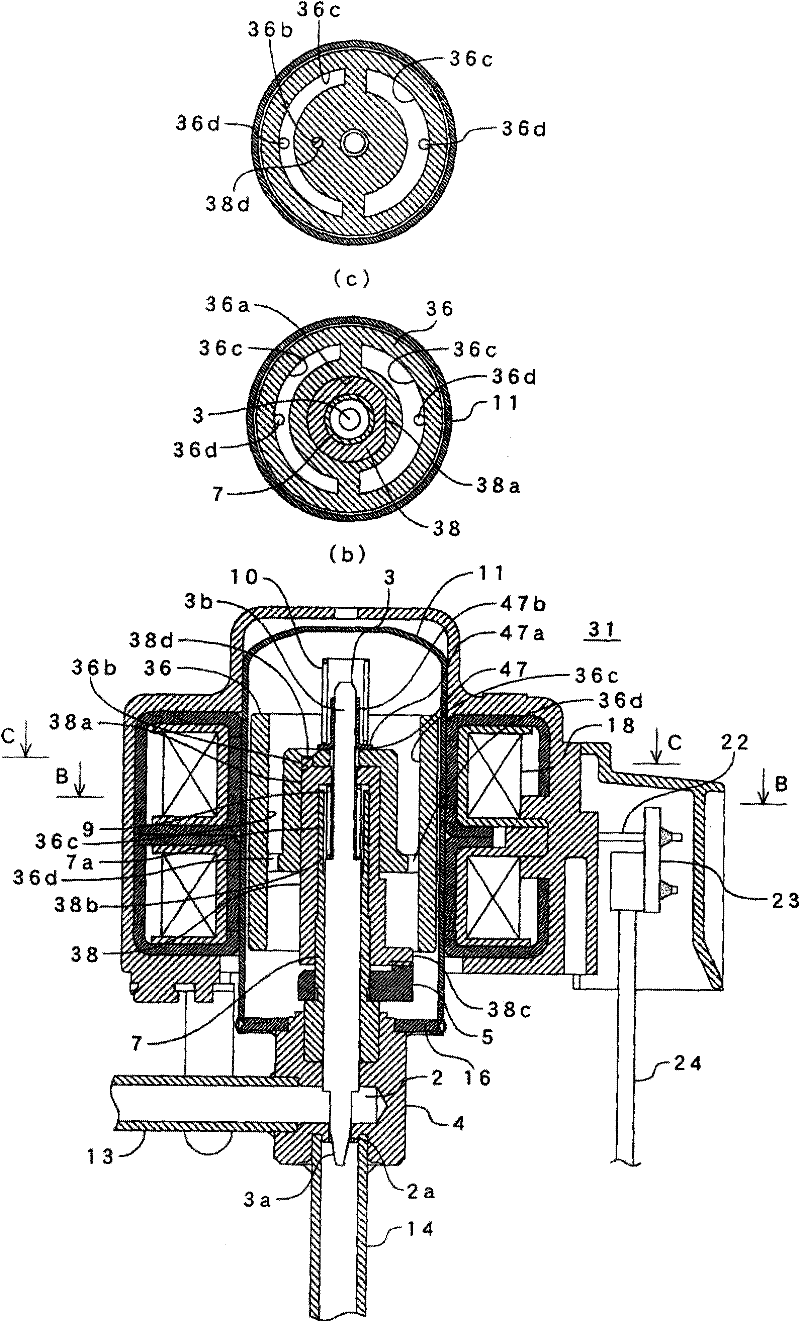

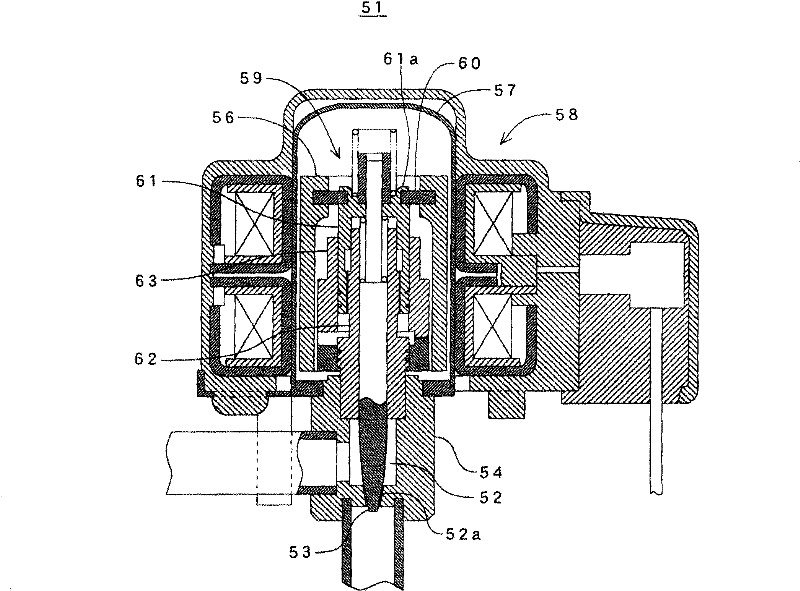

[0065] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0066] figure 1 Representing the first embodiment of the electric valve of the present invention, the electric valve 1 is composed of the following components: a valve body 4 having a valve chamber 2 and a valve hole 2a formed in the valve chamber 2; a valve core 3a, the The valve core 3a is formed at the lower end of the valve stem 3, and opens and closes the valve hole 2a; the casing 11 protruding from the valve body 4; the stator coil 18 arranged outside the casing 11; the stator coil 18 is energized and excited to rotate The rotor 6; the threaded pipe 7 fixed to the valve main body 4; the valve stem frame 8, which is formed to be able to rotate together with the rotor 6, and the valve core 3a passes through the threaded pipe 7 by the screw feed action The valve stem 3 lifts; the valve closing spring 9, which is assembled between the valve stem frame 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com