Small-flow electromagnetic water quality treatment device

A water quality processor and small flow technology, applied in the field of water treatment, can solve the problems of large volume, reduced efficiency of anti-scaling and sterilization, and unsuitable for use in small water appliances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

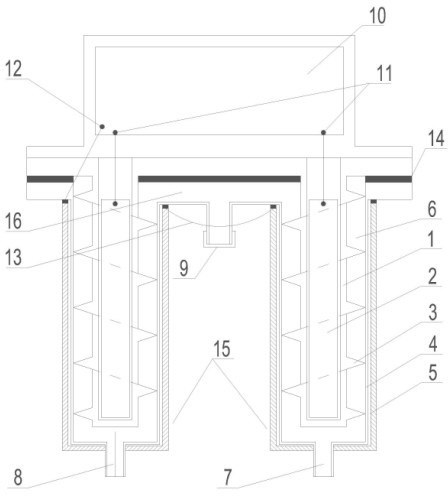

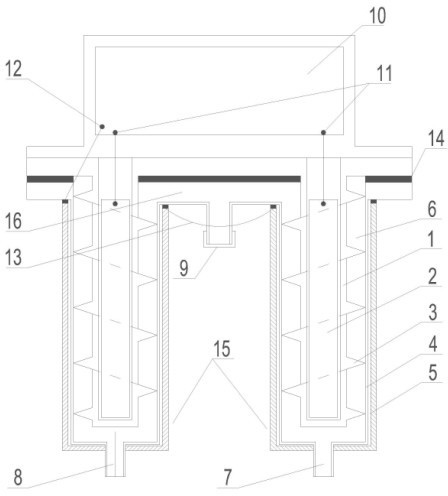

[0008] Embodiments of the present invention will be further described in detail in conjunction with the accompanying drawings.

[0009] This embodiment is suitable for application in small water home appliances such as extremely fast water boilers, coffee machines, water dispensers, and water heaters.

[0010] The small flow electromagnetic water processor consists of screw type anode shell 1, anode electrode 2, anode spiral layer 3, water channel shell 4, cathode electrode 5, water flow channel 6, water inlet 7, water outlet 8, sewage outlet 9, high micro power consumption Frequency oscillator 10, anode high-frequency output line 11, cathode output line 12, multi-cathode connection line 13, water sealing pad 14, water treatment chamber 15, and connecting water channel 16.

[0011] Such as figure 1 As shown, the anode electrode 2 is a metal rod or a metal cylinder, which is installed in the screw-type anode casing 1, and the screw-type anode casing 1 is provided with a spiral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com