Disposable arc-rolling and forming die

A one-time, forming mold technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of poor product consistency, multi-equipment labor, low production efficiency, etc., to reduce equipment resources and human resources. Inputs, improved uniformity, yield and quality improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

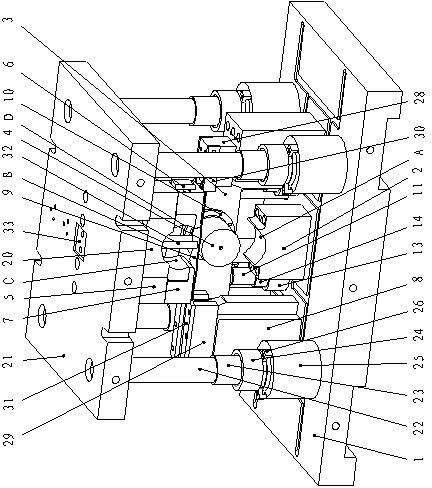

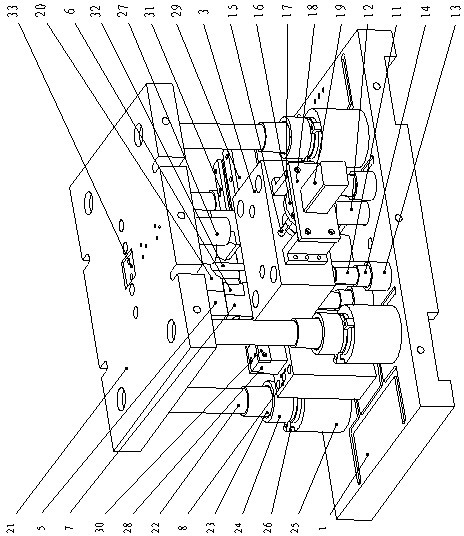

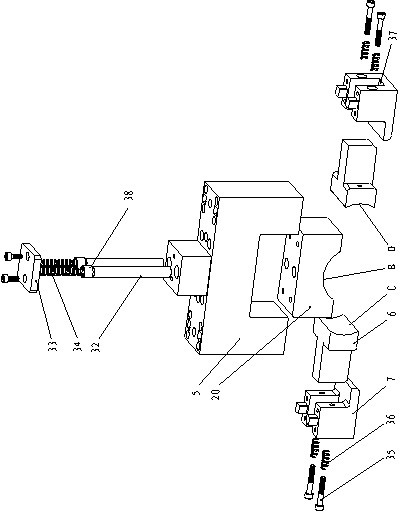

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following embodiments are only examples of the specific implementation of the present invention, rather than limiting the present invention.

[0023] like figure 1 , figure 2 As shown, the disposable roll forming mold of the present invention includes a lower template 1 and a lower template attachment device fixedly connected to a punch press, and an upper template 21 and an upper template attachment device, and also includes a movable plate device, a slideway device, and a pressing device and positioning device.

[0024] The lower formwork accessory device includes a round lower mold 2 fixed on the upper surface of the lower formwork 1, two left and right pieces (a pair) of oblique cuts 8, 4 (one set) guide sleeve seats 25 and 4 (one set) small The guide sleeve 13, the rolling lower die 2 and the lower formwork 1 are positioned and fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com