Mixed silage of alhagi sparsifolia at full-bloom stage and alfalfa and preparation method thereof

A technology of mixing silage and camel thorn, which is applied in the directions of animal feed, animal feed, application, etc., can solve the problems of mixed silage of camel thorn and alfalfa in the early flowering stage, and no literature or report has proposed camel thorn and alfalfa. The effect of improving animal appetite, excellent sensory indicators and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

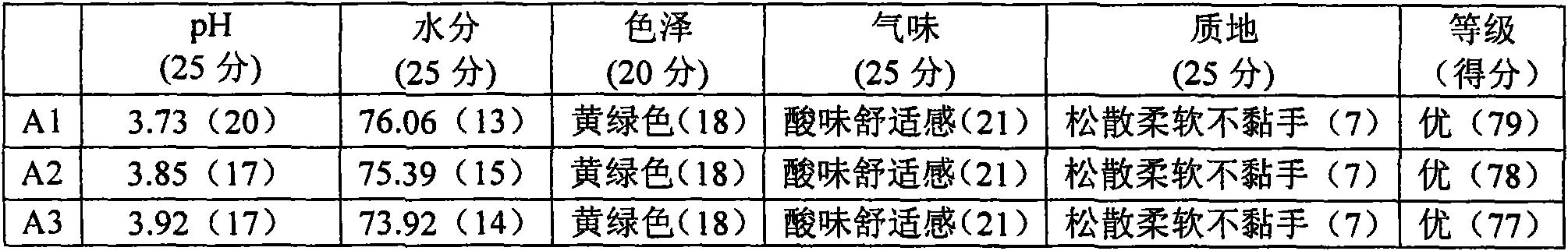

[0056] Example 1-3: Mixed silage of camel spines and alfalfa was prepared by a method consisting of the following steps:

[0057] 1. Harvesting: harvest at the first flowering period of alfalfa and the blooming period of camel thorn.

[0058] 2. Chopping: Cut the fresh alfalfa and camel spines separately into 1~4cm length.

[0059] 3. Mixing: Mix the chopped alfalfa at the first flowering stage and the camel spines at the full flowering stage according to the following weight percentages:

[0060] Alfalfa 70%: Camel spines 30% (A1-Example 1);

[0061] Alfalfa 50%: Camel spines 50% (A2-Example 2);

[0062] Alfalfa 30%: Camel spines 70% (A3-Example 3).

[0063] 4. Filling, compacting and sealing: the mixed raw materials are compacted layer by layer, and filled into a closed container with a density of 550 ~ 600g / L, and airtightness is not leaked;

[0064] 5. Silage fermentation: 20-30℃ (normal temperature) silage fermentation, the fermentation time is 60 days;

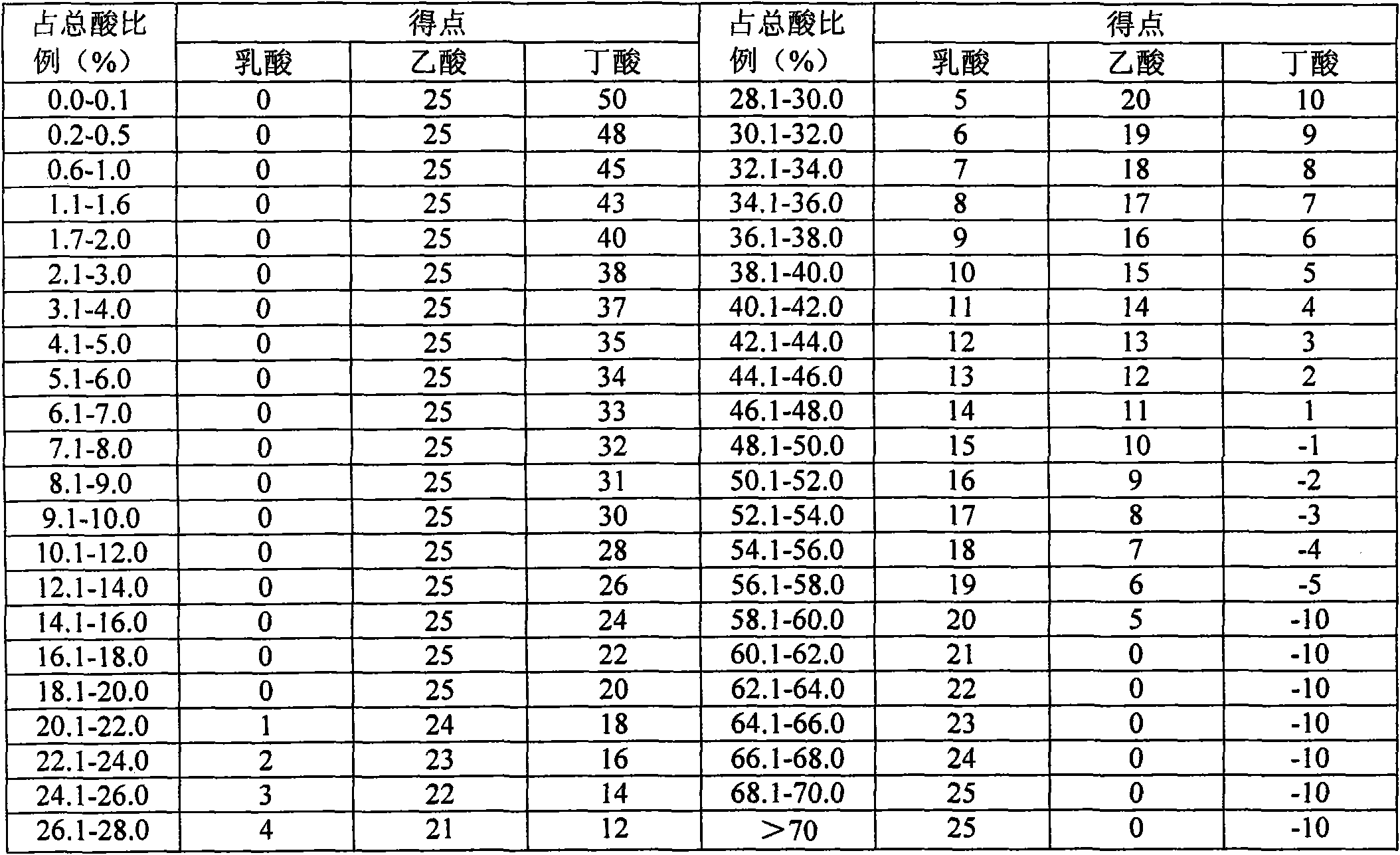

[0065] 6. Product testing: Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com