Heat-radiating device combination and electronic device employing same

A technology of heat sink and radiator, applied to circuits, electrical components, electrical solid devices, etc., can solve problems such as circuit short circuit, increase production cost, burn electronic components, etc., achieve simple and firm assembly, reduce assembly cost, and reduce material cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

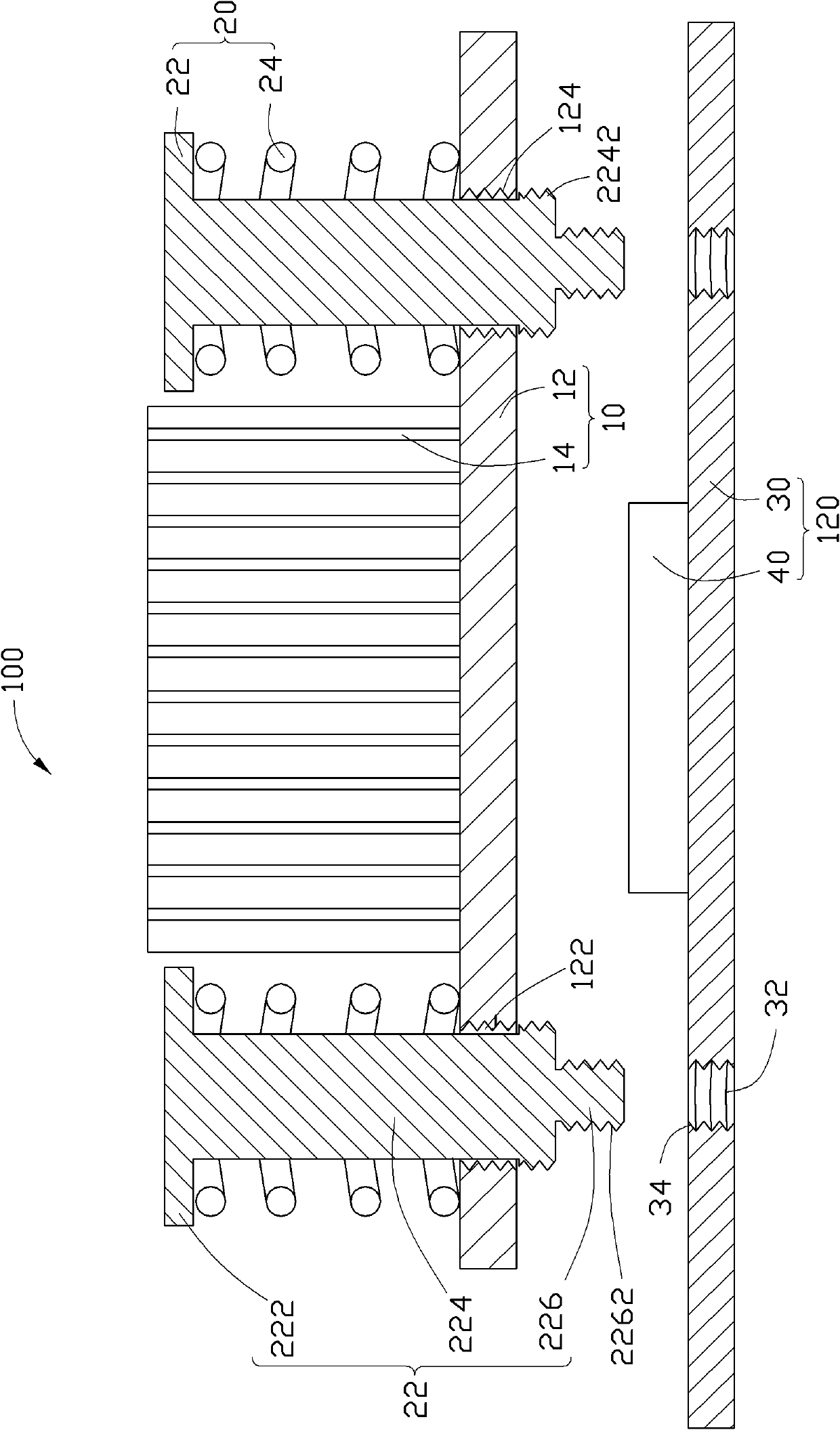

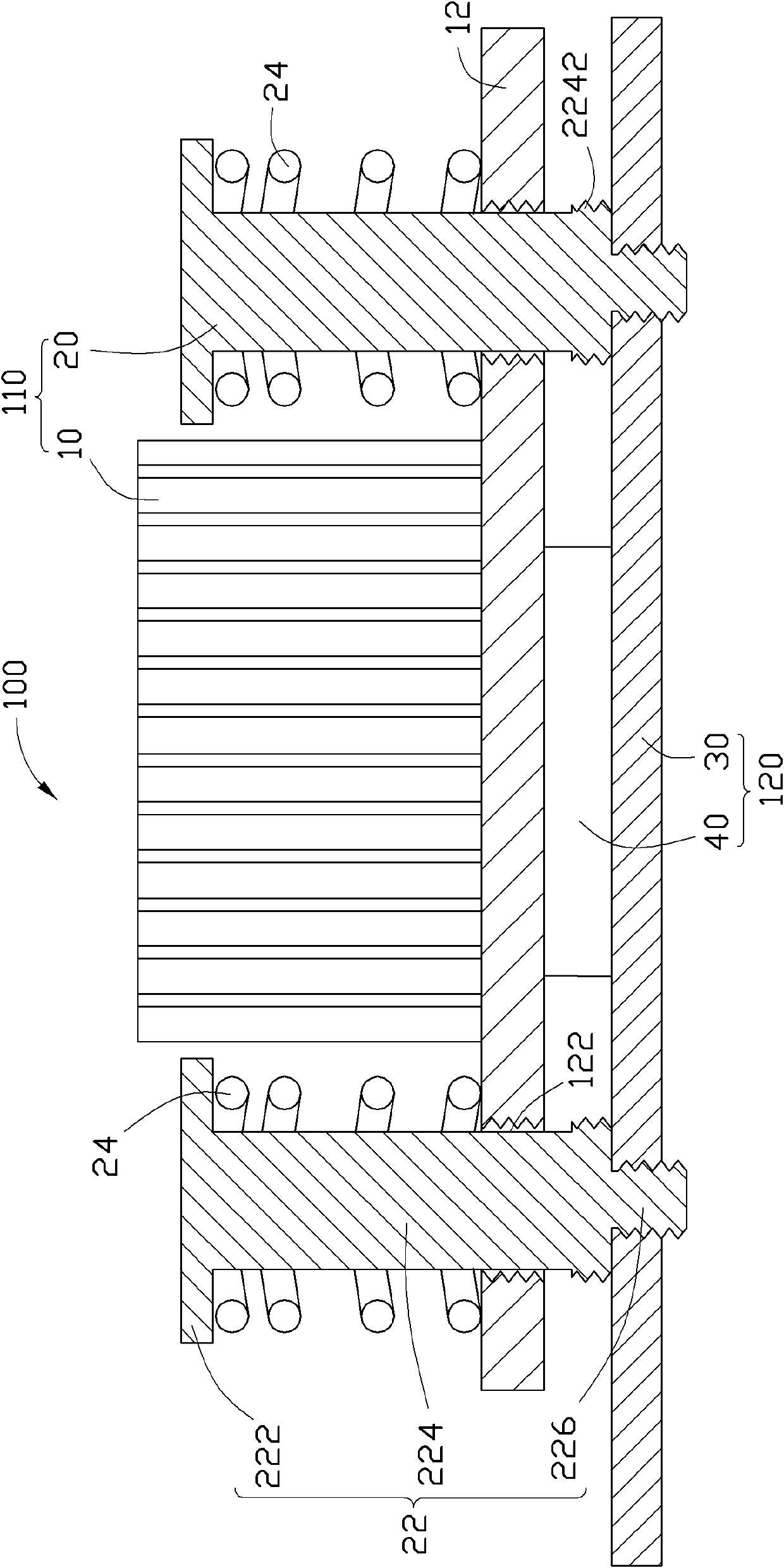

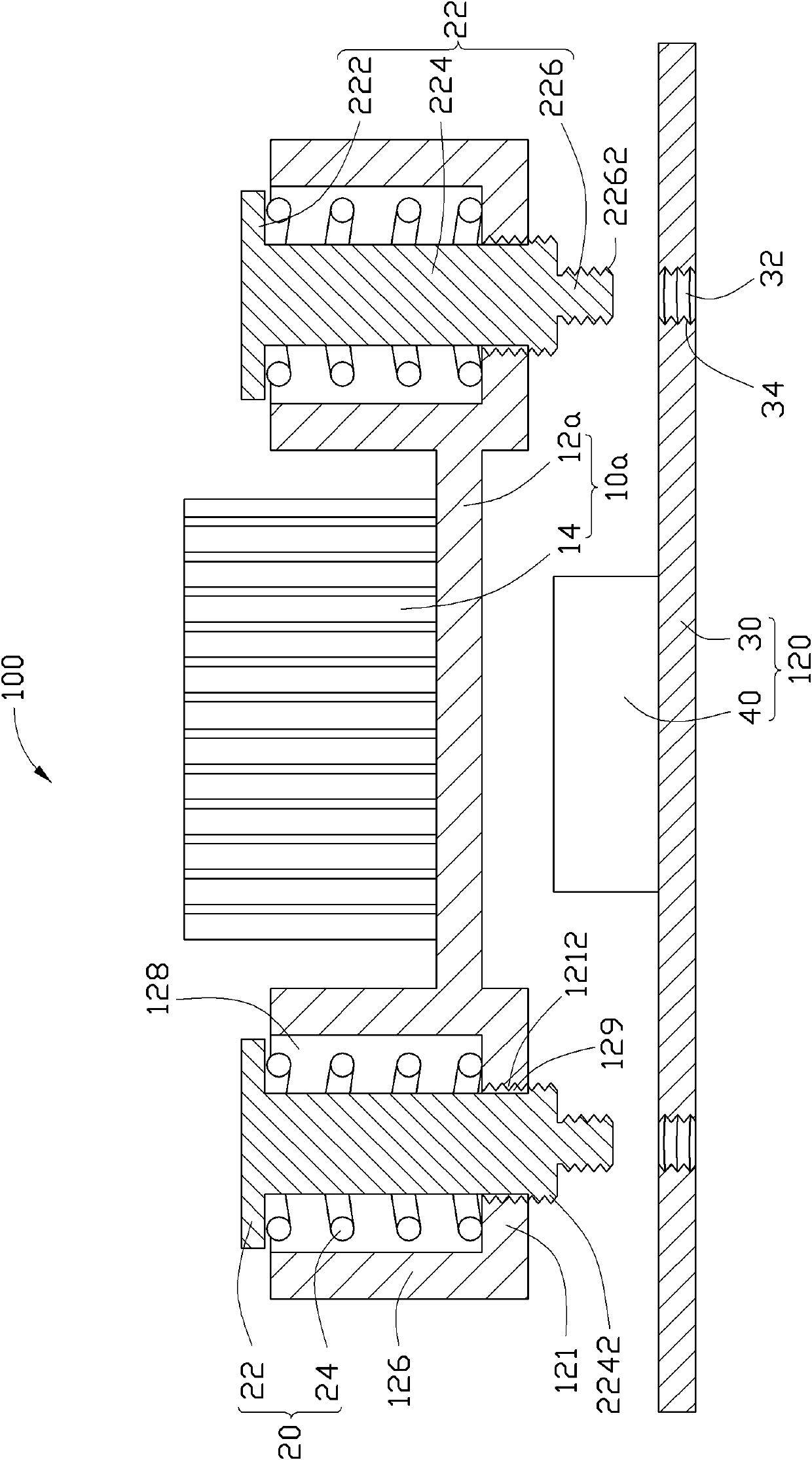

[0037] see figure 1 and figure 2 , which is a cross-sectional view of an electronic device 100 according to the first embodiment of the present invention. The electronic device 100 includes a heat sink assembly 110 and an electronic component 120 . The heat sink assembly 110 is attached to the electronic component 120 for dissipating heat from the electronic component 120 .

[0038] The heat sink assembly 110 includes a heat sink 10 and a plurality of spring screw fasteners 20 .

[0039] The heat sink 10 includes a base 12 and a plurality of cooling fins 14 disposed on the base 12 . These cooling fins 14 are arranged in parallel and at intervals. In this embodiment, the base 12 is a square heat conducting plate. A plurality of spaced first through holes 122 are formed on the base 12 , and an inner wall of each first through hole 122 is tapped with an internal thread 124 . Each first through hole 122 is used for matching with a corresponding spring screw fastener 20 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com