Static multistage melting crystallization method for preparing electronic grade phosphoric acid

An electronic grade phosphoric acid, melt crystallization technology, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of high production cost, long operation time, high purity requirements, etc., and achieve good market prospects and industrialization value, Mild operating conditions and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Close the valve at the bottom of the crystallization tower, and place 2400 g of raw material food-grade phosphoric acid liquid (the content of metal ion impurities as shown in Table 1) in the crystallization tower at one time. Cooling water was passed through the jacket of the crystallization tower, the raw material was cooled to 21.5°C, and 10 g of solid seed crystals were added to the feed liquid of the crystallization tower at a constant temperature, and dispersed evenly.

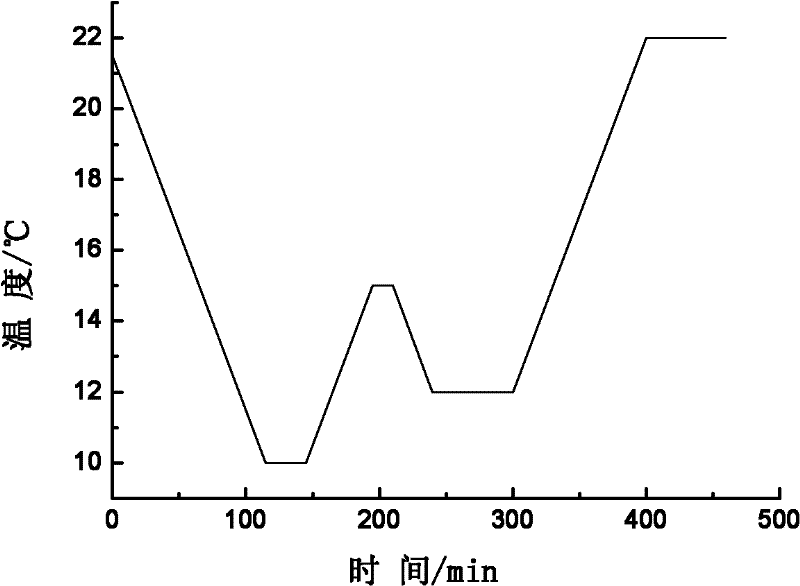

[0041] Continue to feed the cooling medium, lower the temperature at a rate of 6°C / h, and the crystals grow uniformly into crystal columns inside the crystallization tower. Cool down to 10°C to reach the primary crystallization temperature, discharge 1 / 2 of the uncrystallized mother liquor 586g after constant temperature for 30 minutes, and measure the quality of the mother liquor by the weighing device at the bottom of the tower. Then close the valve, pass hot water through the jacket of the crys...

Embodiment 2、3、4

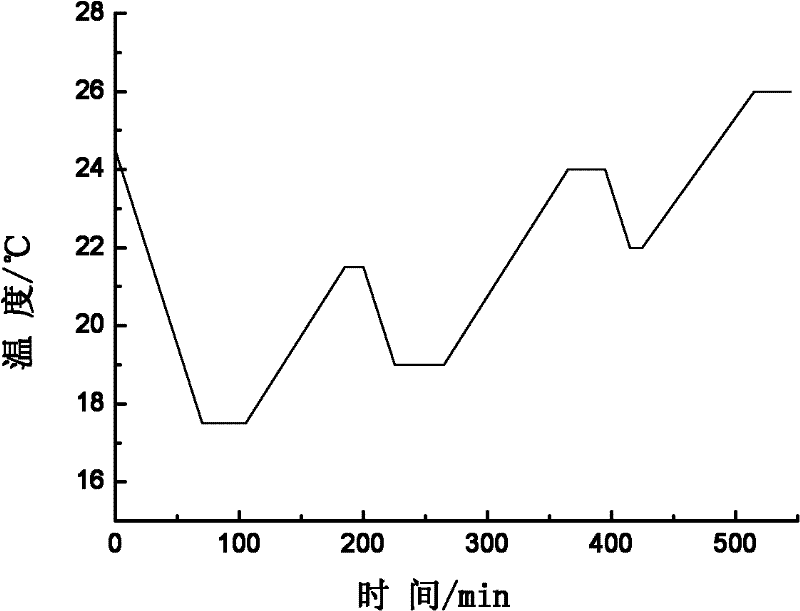

[0047] Close the valve at the bottom of the crystallization tower, and place 2400 g of raw material food-grade phosphoric acid liquids of different mass concentrations (the metal ion impurity content is as shown in Table 3) in the crystallization tower at one time. Cool the raw materials to an appropriate temperature, add the pre-prepared seed crystals into the crystallization tower feed liquid, and disperse evenly. Then start the operation of step-by-step material cooling crystallization-constant temperature-discharging part of the mother liquor-heating melting-constant temperature, the specific parameters are shown in Table 2. The material temperature operating curve of the process is as follows figure 2 , 3 , 4 shown. The test results of raw materials and products are shown in Table 3.

[0048] Table 2 One-time static multi-stage melting and crystallization operating parameters

[0049]

[0050] Table 3 Raw material phosphoric acid, test results of one static multi-...

Embodiment 5

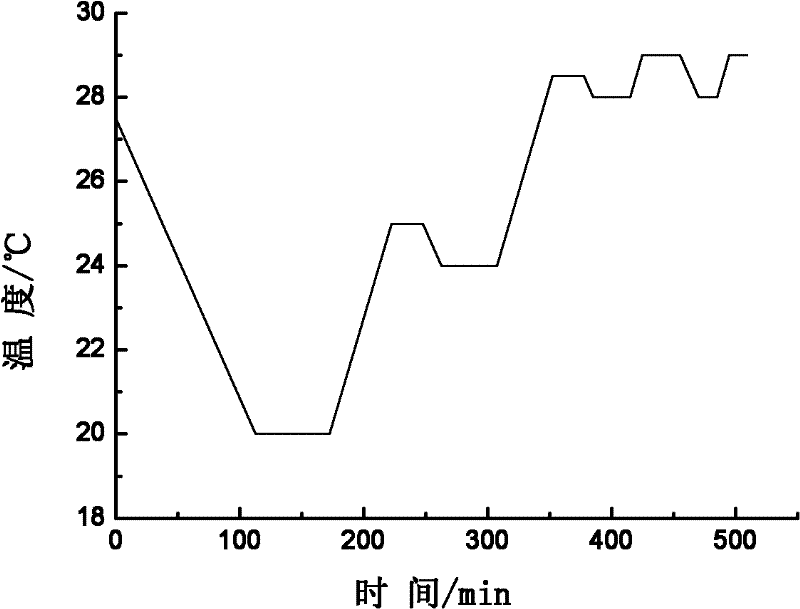

[0054] Close the valve at the bottom of the crystallization tower, and place 3000 g of food-grade phosphoric acid liquid with a mass concentration of 83% (the content of metal ion impurities as shown in Table 4) in the crystallization tower at one time. Cool the raw material to 15°C, add 100 g of pre-prepared seed crystals into the feed liquid, and disperse evenly.

[0055] Continue to feed the cooling medium and start to lower the temperature at a rate of 4°C / h, and the crystals grow uniformly into crystal columns inside the crystallization tower. Cool down to 6°C to reach the primary crystallization temperature, discharge 1 / 4 of the uncrystallized mother liquor 450g after constant temperature for 60min, and measure its mass by the weighing device at the bottom of the tower. Then close the valve, raise the temperature at a rate of 6°C / h to the primary melting temperature of 12°C for 15 minutes, then continue to cool down at a rate of 4°C / h to the secondary crystallization tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com