Sugarcane leaf grinding device

A technology for crushing leaves and sugarcane, applied in the direction of cutters, agricultural machinery and tools, applications, etc., can solve the problems of unstable transmission speed, clean peeling, and affecting the effect of leaf peeling, so as to prevent scratches and ensure the effect of leaf peeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

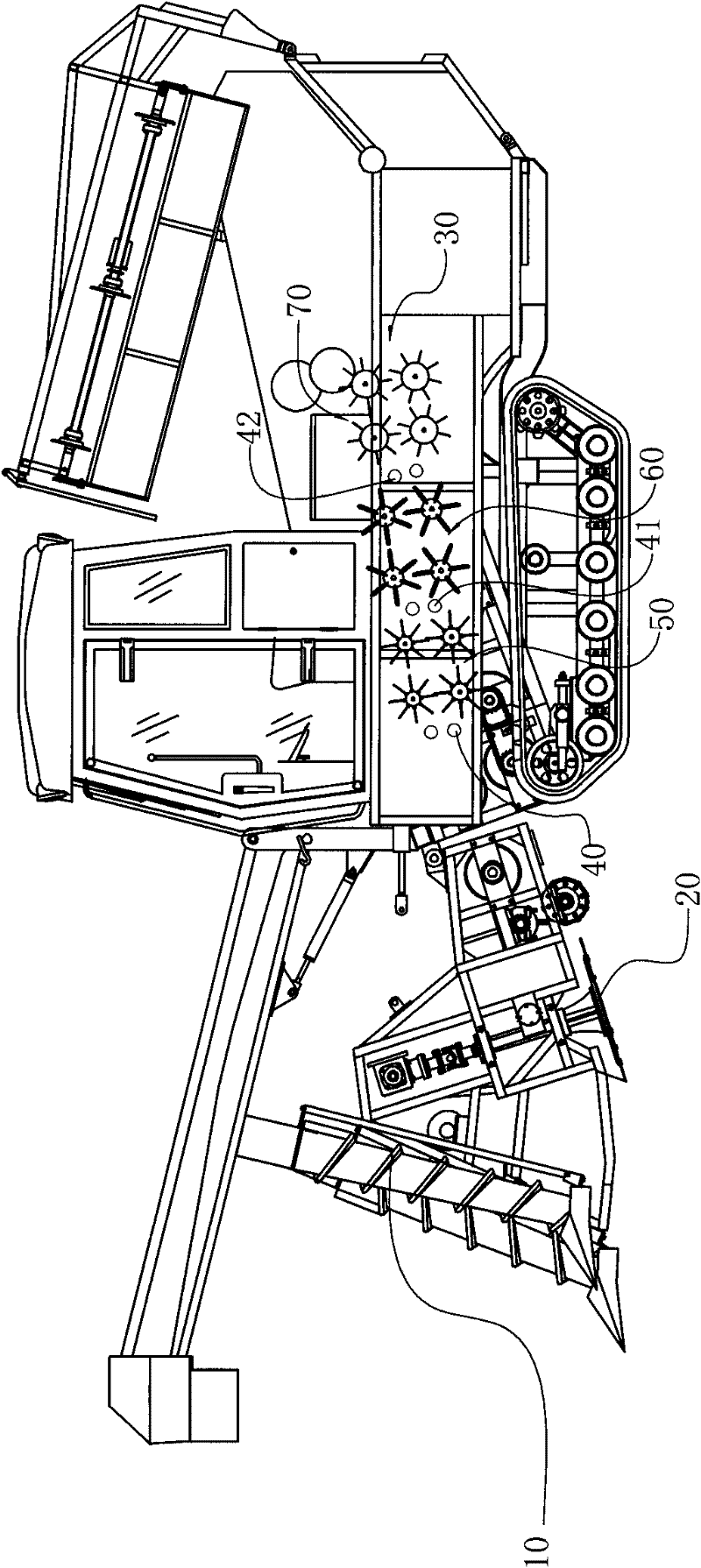

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

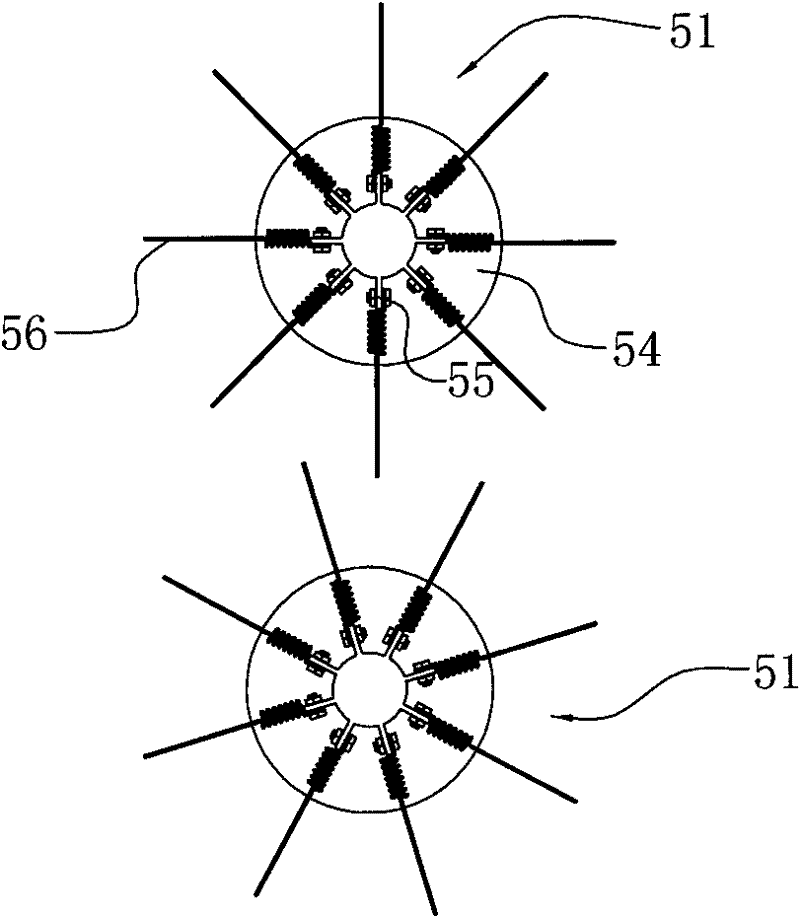

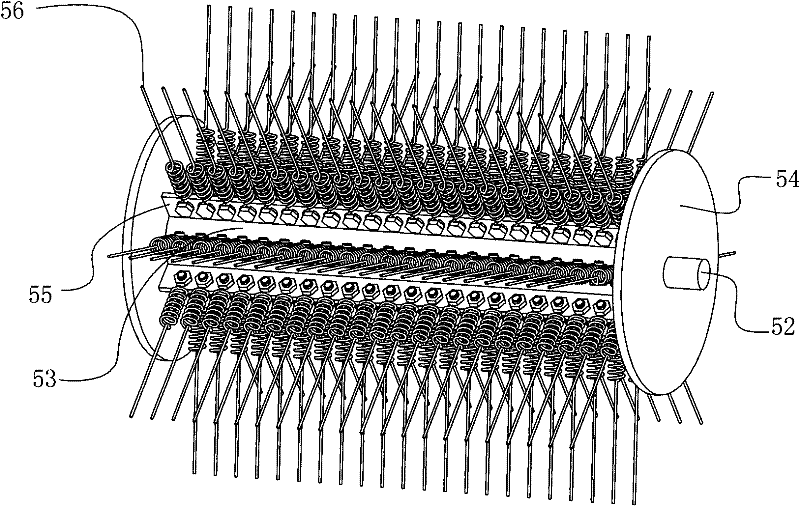

[0021] like Figure 2-5 As shown, the leaf crushing device 50 includes at least a pair of crushing impellers 51 correspondingly arranged up and down in the transmission channel. The crushing impellers 51 include a central shaft 52 and a drum 53 for installation, and flanges at both ends of the drum 53. The blue surface 54, and on the outer peripheral surface of the drum 53, a plurality of fixing pieces 55 extending in the axial direction of the drum 53 are uniformly provided. The central shaft 52 is located at the radial center of the drum 53 and the drum 53 rotates around the central shaft 52 . The fixed plate 55 is provided with a row of fixing holes 551 along the axial direction of the drum 53, and each fixing hole 551 is fixed with a steel wire 56 extending radially along the drum 53 by a screw 552, so the steel wires 56 are distributed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com