Cable supplying and rotating system

A technology for cable and supply equipment, which is applied in the field of cable supply and rotation systems, can solve the problems of occupying a large space, complex equipment structure, low efficiency of system power utilization, etc., and achieve the effect of simplifying the structure and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

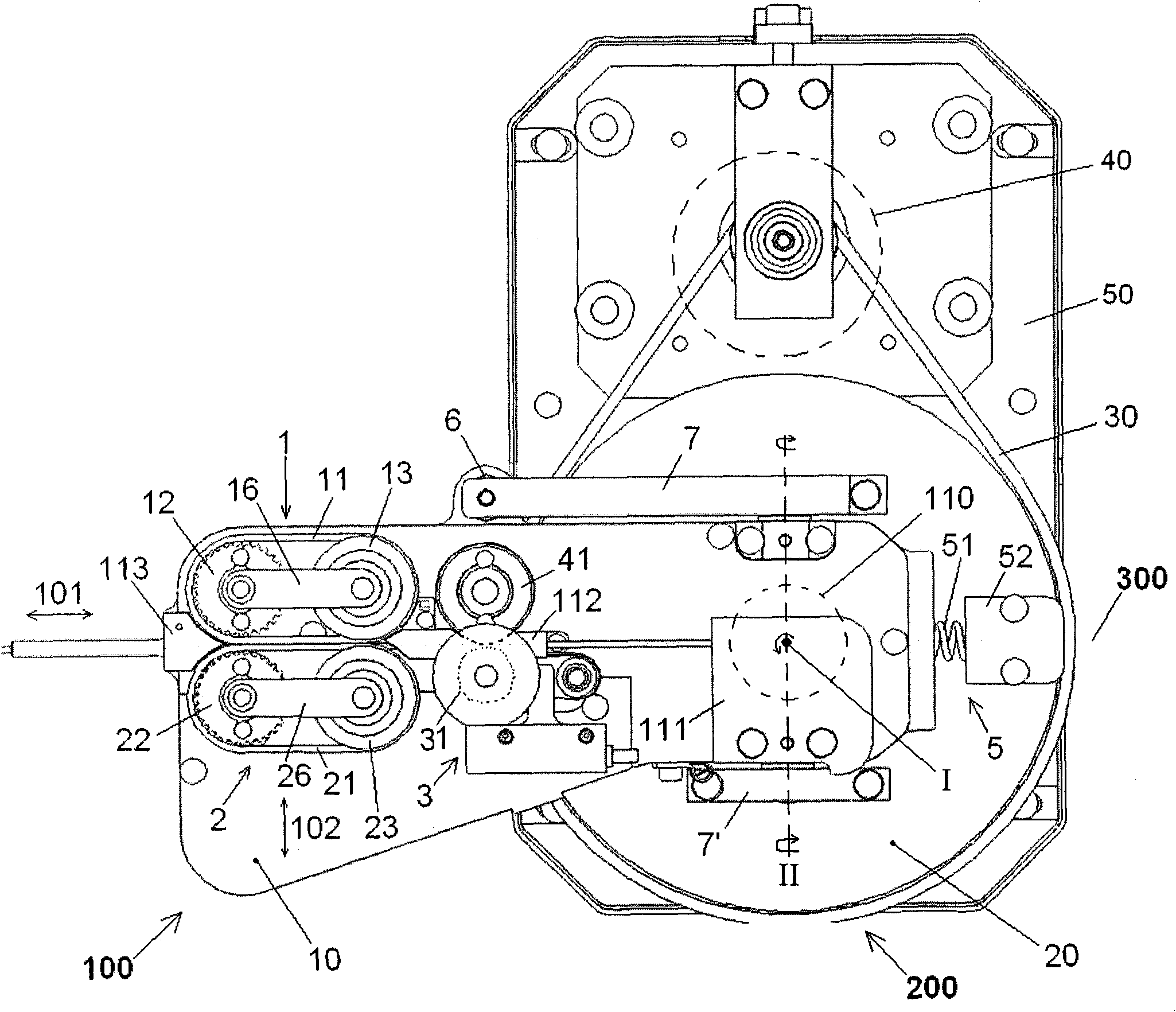

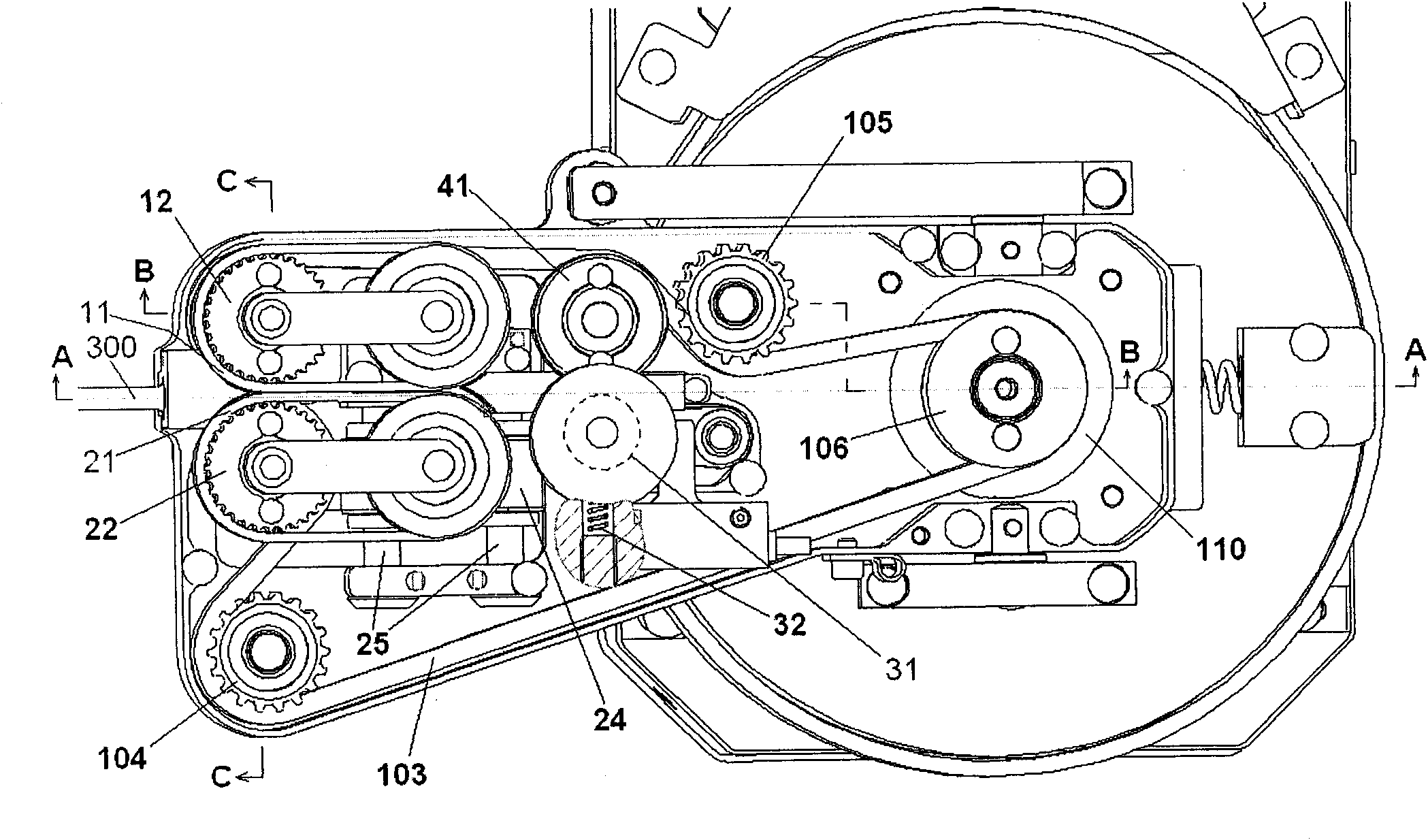

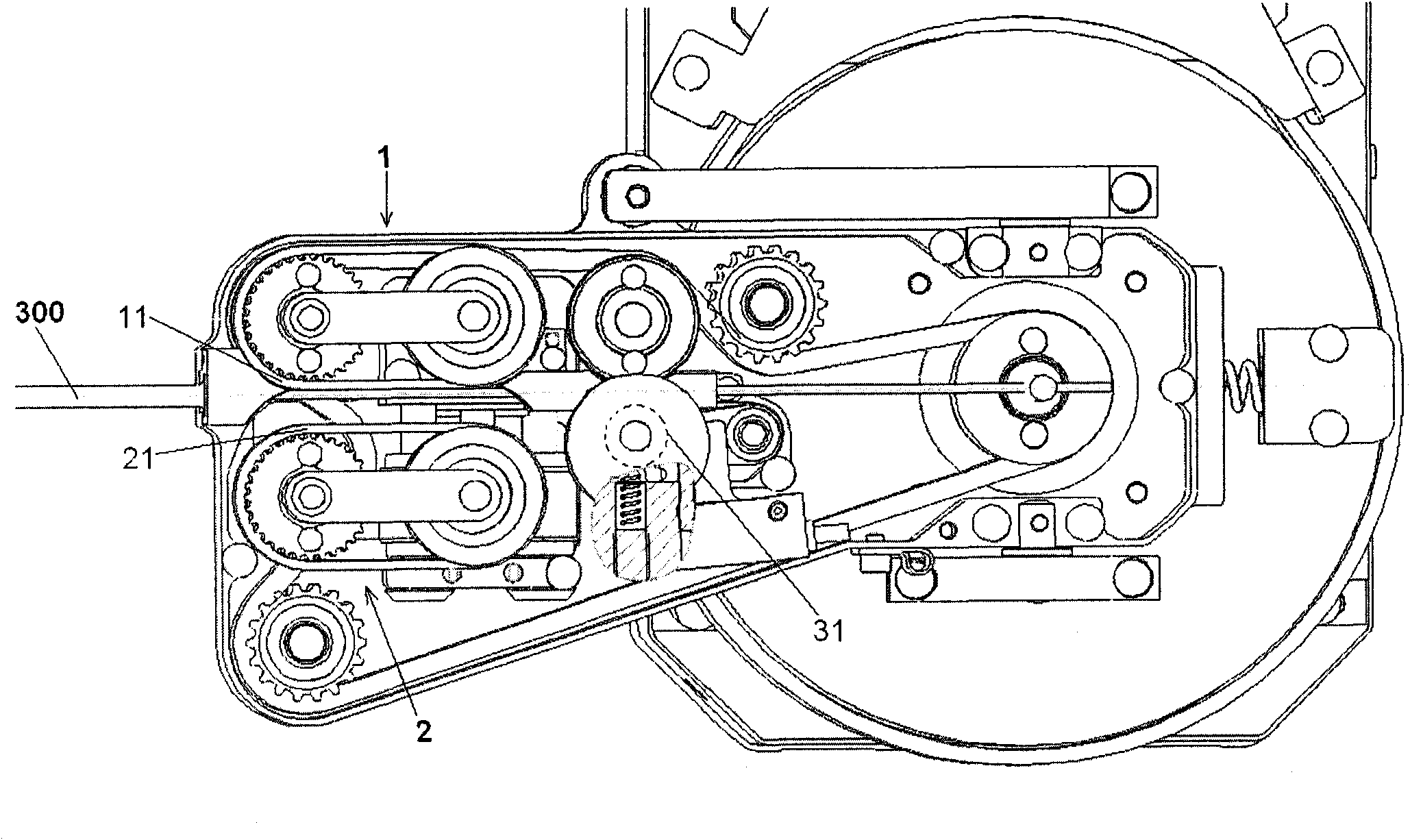

[0044] Figure 1 to Figure 7 A first embodiment of the cable feeding and rotating system of the present invention is shown.

[0045] figure 1 A top view of a cable feeding and rotating system according to a first embodiment of the invention is shown. Such as figure 1 As shown, in this embodiment, the cable supply and rotation system mainly includes a cable supply device 100 and a rotation device 200 . The cable supply device 100 is configured to supply a cable 300 of a predetermined length to a cable processing mechanism, such as a cable cutting mechanism (not shown). The rotating device 200 is used to rotate the cable supply device 100 to different positions, so as to perform other operations on the cable except cutting, for example, crimping a terminal on the cable end.

[0046] More specifically, in this embodiment, as figure 1 As shown, the cable supply device 100 mainly includes a pair of cable driving devices 1 and 2 facing each other and a cable length detecting de...

no. 2 example

[0088] Figure 8 A top view of a cable feeding and rotating system according to a second embodiment of the invention is shown.

[0089] Compared with the cable feeding and rotating system of the first embodiment, the cable feeding and rotating system of the second embodiment differs only in that a pair of friction rollers 12', 22' are used instead of one of the first embodiment. For belt drives 1, 2.

[0090] Apart from that, other structures of the cable feeding and rotating system of the second embodiment are completely the same as those of the first embodiment, therefore, for the purpose of brevity, the same parts can be referred to the previous Figure 1 to Figure 7 , which will not be described in detail here.

[0091] Specifically, in Figure 8 In the second embodiment shown, the fixed cable drive 1 comprises a first friction roller 12'; the movable cable drive 2 comprises a moving block 24 (see figure 2 ) and a second friction roller 22'.

[0092] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com