Freezer with liquid cryogen refrigerant and method

A technology of liquid refrigerant and freezer, which is applied in household refrigeration equipment, preparation and application of test samples, and can solve problems such as loss of biological materials and increased power demand for equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

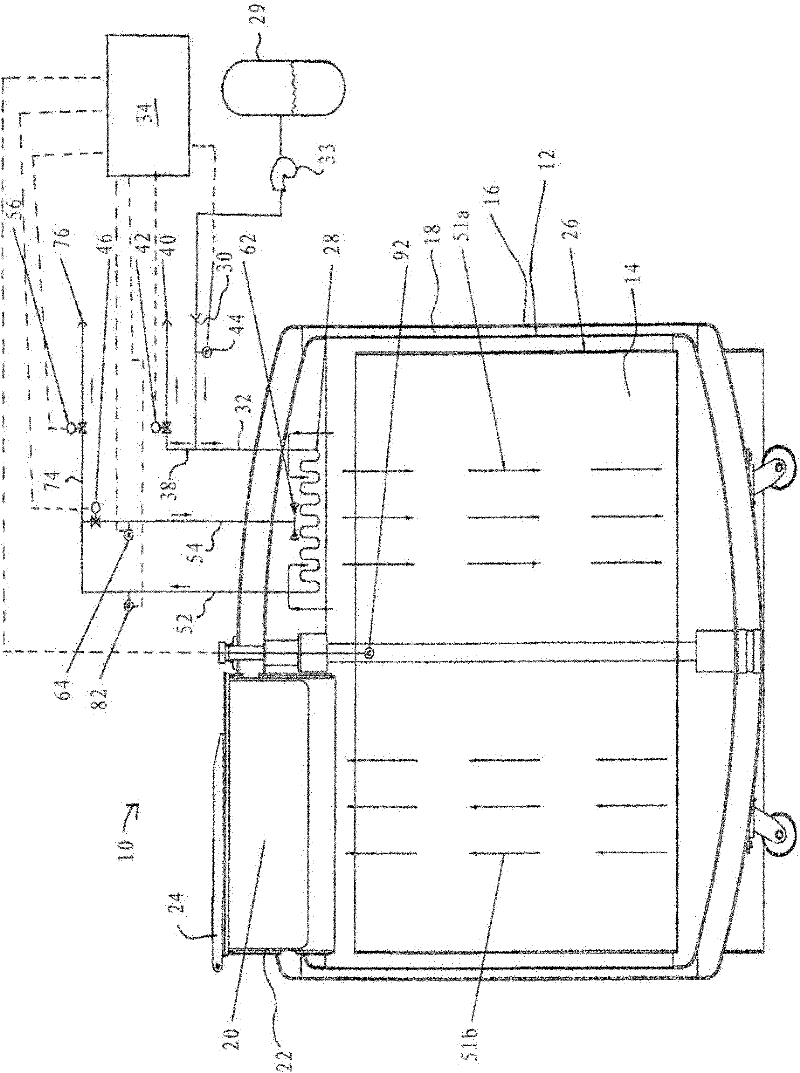

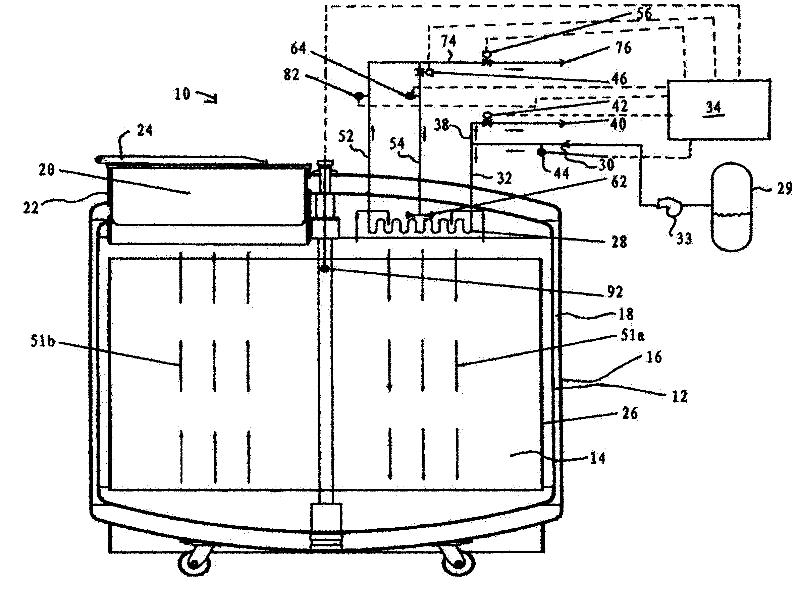

[0010] exist figure 1 In general, 10 denotes an embodiment of the freezer using a liquid refrigerant according to the present invention. The freezer includes an inner container 12 defining a storage compartment 14 . An outer cover 16 generally surrounds the container 12 defining an insulating space 18 between the inner container 12 and the outer cover 16 . A vacuum is preferably drawn in the insulating space 18 such that the storage chamber 14 is insulated. In alternative embodiments, the vacuum insulation space 18 may be supplemented or replaced with insulating materials known in the art, including but not limited to foam or fiberglass.

[0011] An insulating plug or cover 20 is removably disposed within an off-center access opening 22 of the freezer allowing access to the storage chamber 14 . The lid 20 is preferably mounted to the remainder of the freezer by hinged brackets 24 . A rotating disk 26 is disposed within the storage compartment 14 and holds stored items whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com