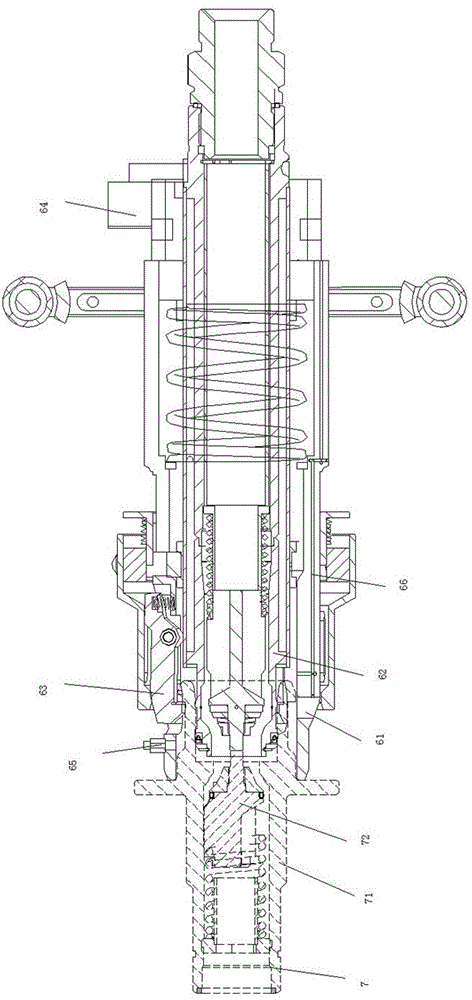

Intelligent filling gun

A filling gun and intelligent technology, applied in the field of intelligent filling guns, can solve the problems of high labor intensity, waste of manpower and material resources, frostbite of personnel, etc., and achieve the effect of reducing labor intensity, convenient operation, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

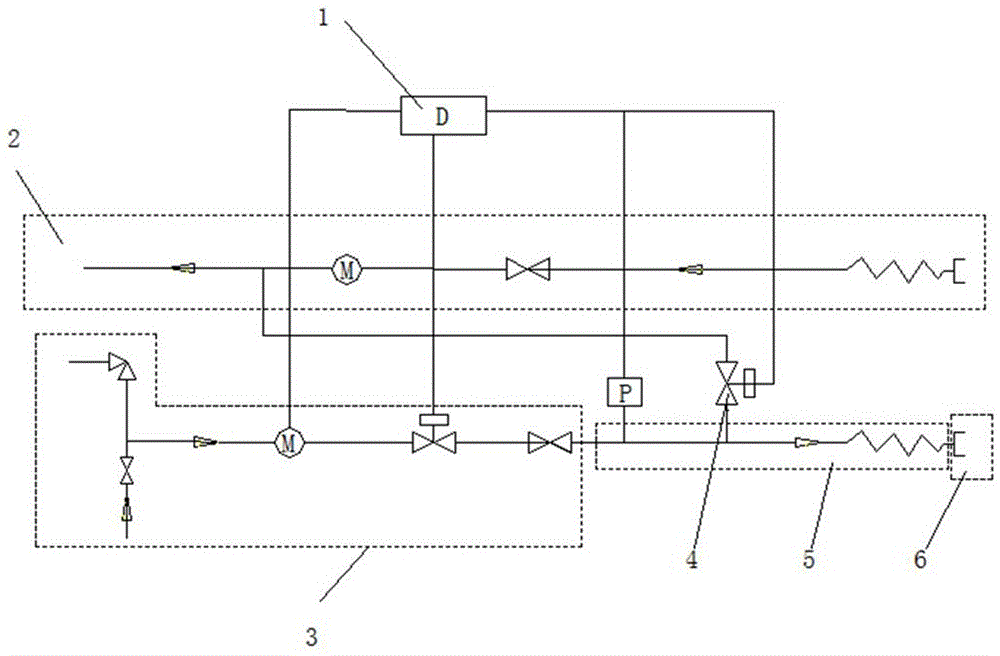

Method used

Image

Examples

Embodiment 2

[0044] Based on the intelligent filling gun and its supporting system of embodiment 1, the method for pulling out the filling gun body 6 comprises the following steps:

[0045] Step 1: Close the LNG system, disconnect the connection between the inner barrel and the device to be filled, and lock the connection between the outer barrel and the device to be filled;

[0046] Step 2: The detector detects the pressure change between the inner barrel and the outer barrel at the interface of the filling gun body. When the pressure change reaches the set value, open the pressure relief solenoid valve until the pressure in the filling gun is lower than the set value value, then close the pressure relief solenoid valve and unlock the connection between the outer barrel and the filled device.

Embodiment 3

[0048] Based on the intelligent filling gun and its supporting system of Embodiment 1, the filling steps of LNG or other low-temperature medium are as follows:

[0049] Purge: Manually connect the outer barrel of the filling gun body to the filled device, and lock the connection between the outer barrel and the filled device, and then use nitrogen to purge the interface of the filling gun body;

[0050] Filling: the inner barrel slides relative to the outer barrel, so that the filled device communicates with the inner barrel, and then the LNG system is turned on;

[0051] Detection: After the filling is completed, close the LNG system, control the inner barrel to slide relative to the outer barrel and separate from the filled device, the connection between the outer barrel and the filled device remains locked, and the detector detects the interface of the filling gun body pressure changes;

[0052] Pressure relief: When the pressure change at the interface of the filling gun ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com