Long-distance control wellhead operation device for workover operation

A technology of remote control and operation device, used in the automatic control system of drilling, wellbore/well components, drilling equipment, etc. Effects of mechanization and automation, high levels of mechanization and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing:

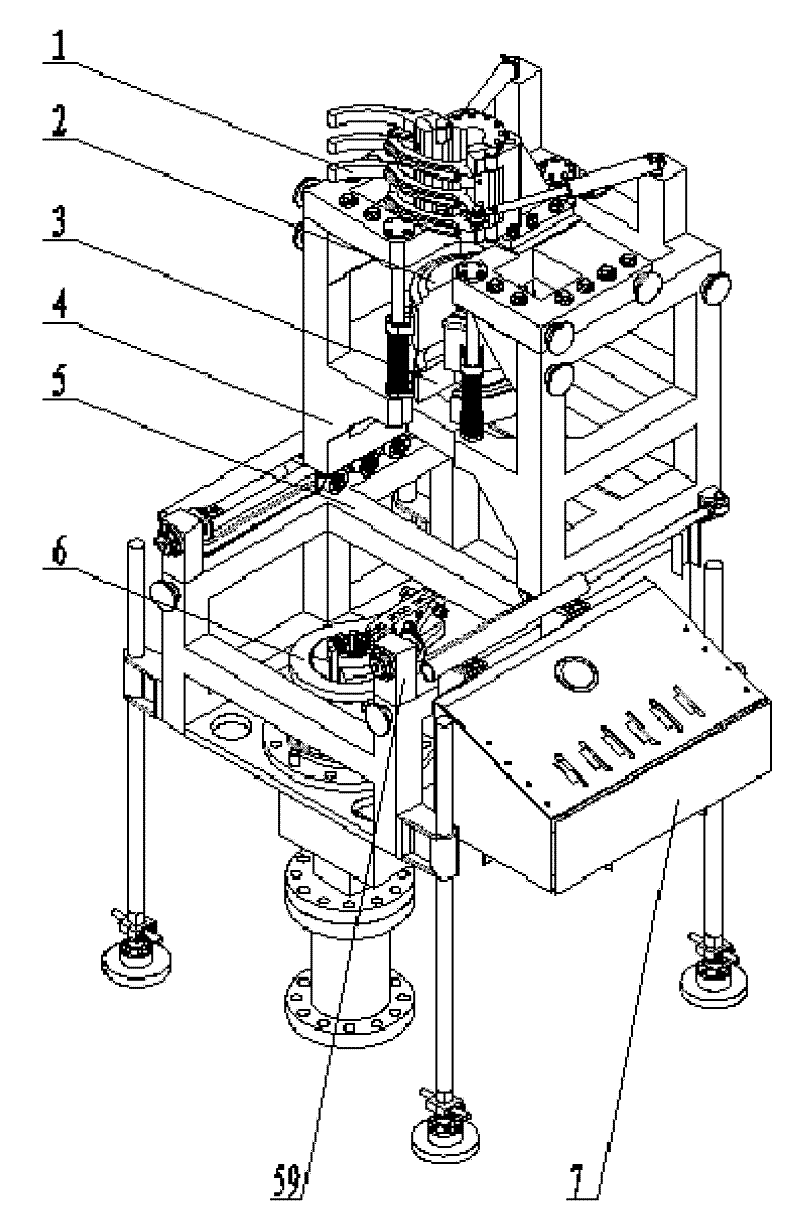

[0048] This kind of workover operation remote control wellhead operation device, its overall structure diagram is as follows figure 1 As shown, it is divided into upper, middle and lower three parts, which are respectively called the righting manipulator 1, the mobile operator 4 and the base.

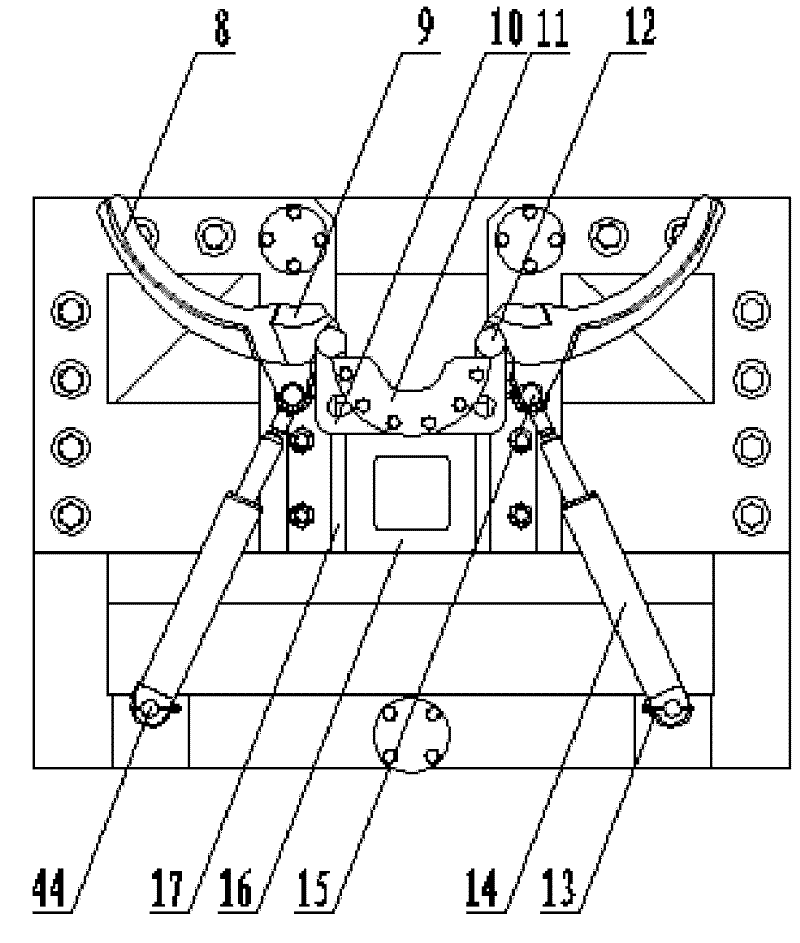

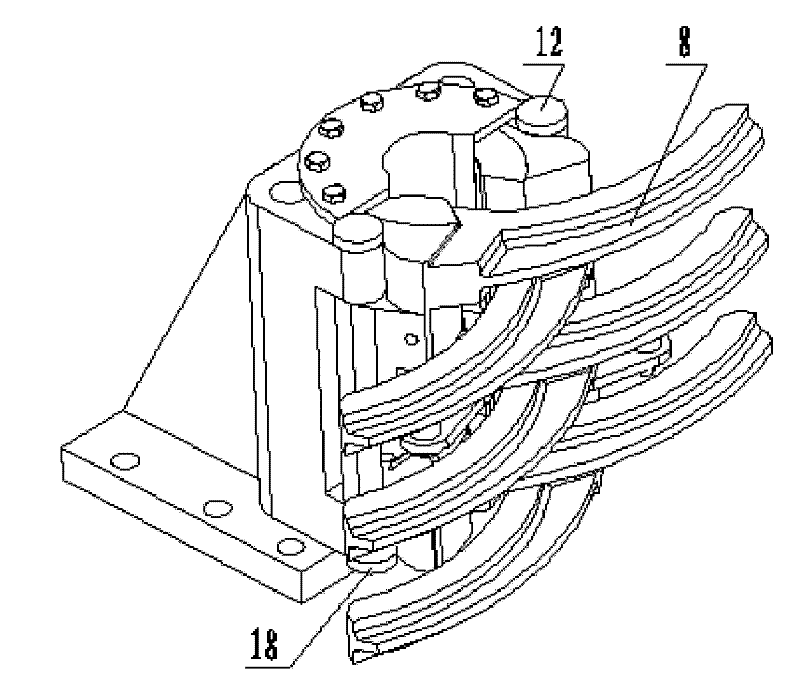

[0049] Wherein, the structure of the righting manipulator 1 is as figure 2 combine image 3 Shown, by righting manipulator claw 8, righting manipulator claw bushing 9, righting manipulator rear seat 10, righting manipulator rear seat bushing 11, righting manipulator rotating shaft 12, cotter pin 13, righting manipulator hydraulic cylinder 14, righting manipulator pin shaft 15. The bottom plate 16 of the righting manipulator, the rear rib plate 17 of the righting manipulator, the gasket 18 of the rotating shaft of the righting manipulator and the support shaft 44 of the hydraulic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com