Coiling device and method for processing material web coil

A technology of winding device and material web, applied in the field of paper web or cardboard web winding device, paper web or cardboard web field, can solve the problems of small quantity, expensive, time-consuming, etc., achieves small effective arm and good use of space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

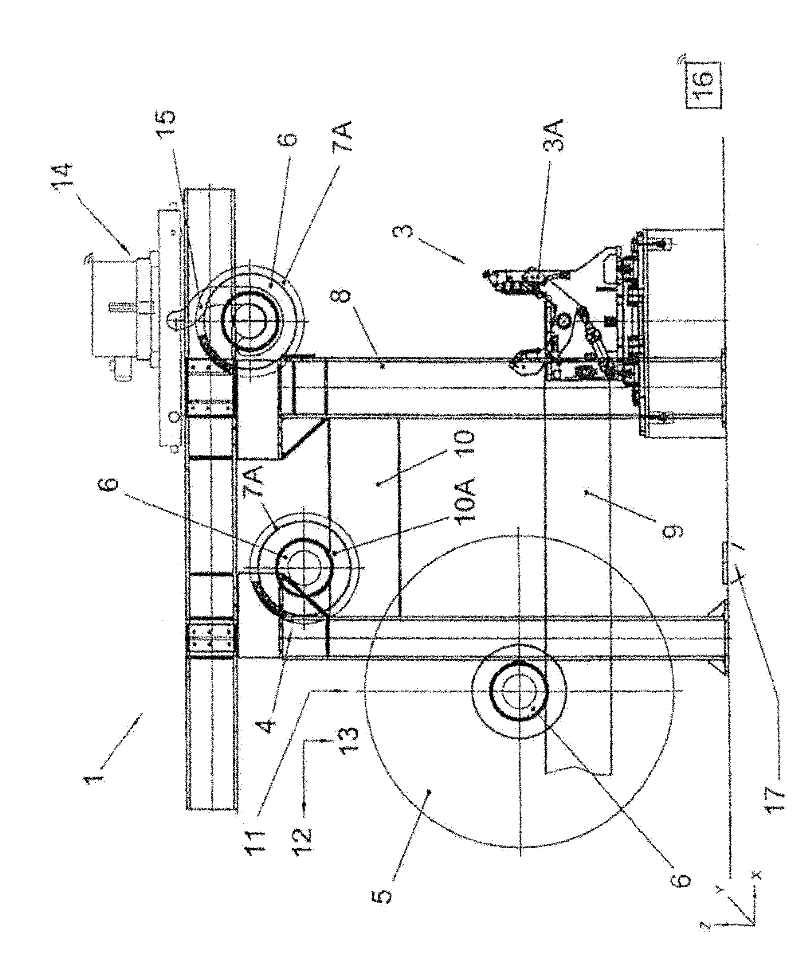

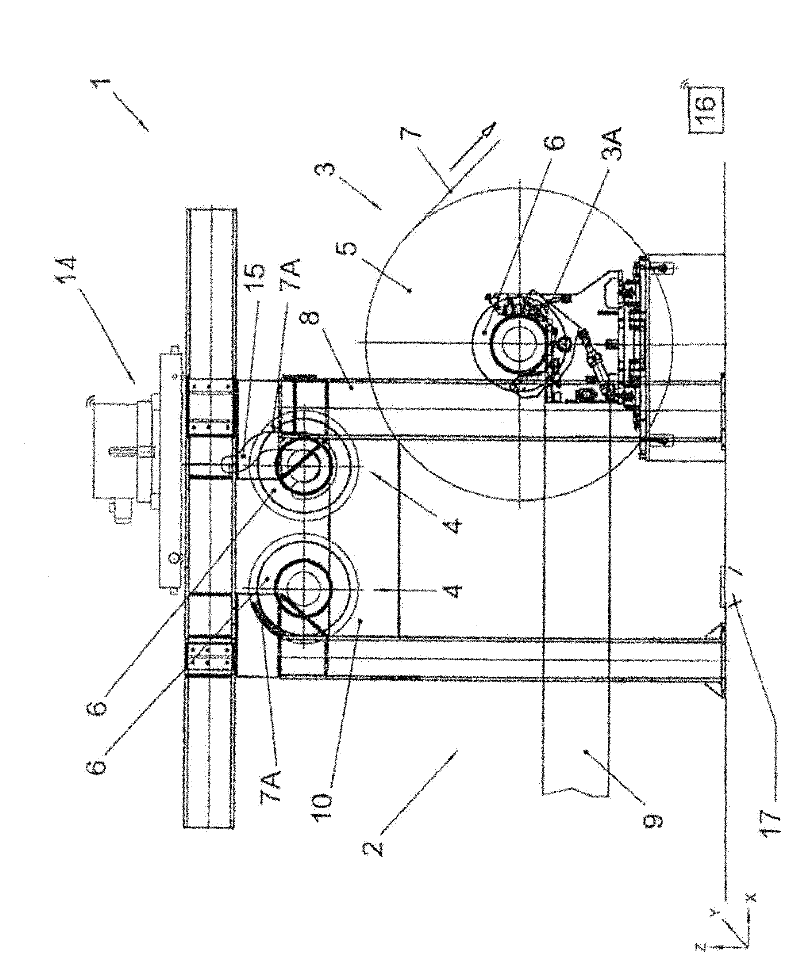

[0054] The preferred embodiment of the winding device 1 according to the invention shown in the drawing is in the example shown a component of a web roll cutting machine in the "offline" state in a paper mill. The direction in space is given by the coordinate system. The winding device 1 has a ready position 2 in which a complete web roll 5 wound on a roll core 6 can be supported. From this ready position 2 the web roll 5 can be quickly placed into the unwinding position 3 . For this purpose, in the preferred embodiment shown, on the left and right of the preparation position 2 there is provided an introduction guide 9 which slopes slightly toward the unwinding position. It is also conceivable here that the introduction rail is designed horizontally and has a transport device, for example in the form of a transport trolley or a stopping and accelerating device. The functional positions, ie the ready position 2 , the unwinding position 3 and the subsequent position 4 describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com