Hydraulic locking structure for numerical control milling and drilling machine

A locking structure, drilling and milling machine technology, applied in metal processing equipment and other directions, can solve problems such as being unsuitable for enterprise processing and production, and the self-locking function of the servo motor cannot ensure the spindle quickly, effectively and accurately, and achieves simple structure and stable operation. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

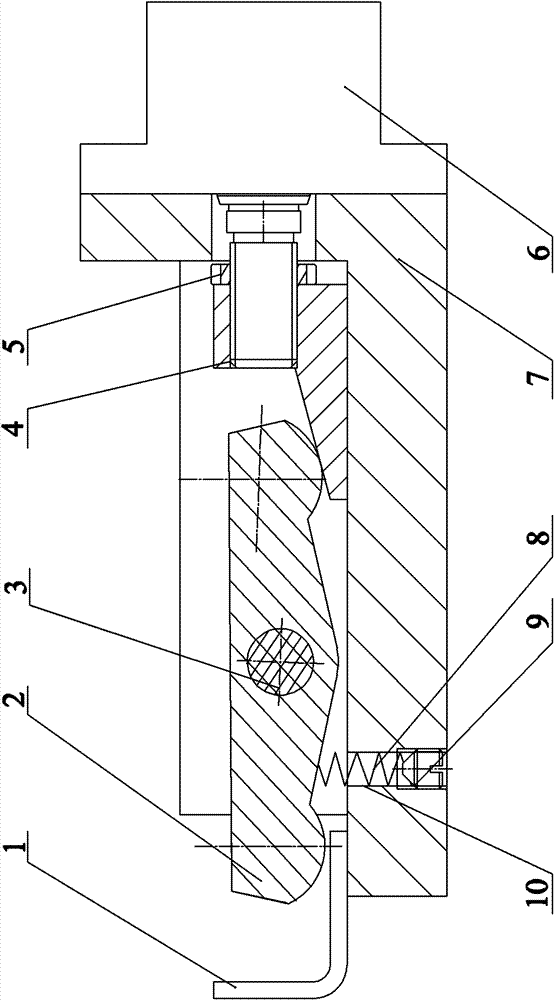

[0010] As shown in the figure, the present invention mainly consists of locking bar 1, jaw bridge plate 2, jaw pin shaft 3, oblique wedge plate 4, round nut 5, oil cylinder 6, jaw body 7, locking spring 8, tightening Screw 9 is formed with parts such as back-moving spring hole 10.

[0011] The hydraulic locking structure of the CNC drilling and milling machine includes a locking oil cylinder 6 fixedly installed at one end of the jaw body 7, a locking bar 1 is installed at the other end of the jaw body 7, and a lock bar 1 is installed between the locking oil cylinder 6 and the locking cylinder 6. The jaw body 7 between the bars 1 is hinged with a jaw bridge plate 2, and a slanted wedge plate 4 is fixedly installed on the piston rod of the locking cylinder 6, and the slanted wedge plate 4 is inserted into one end of the jaw bridge plate 2. Between the jaw body 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com