Prepregs with improved processing

一种预浸料、复合材料的技术,应用在预浸渍纤维领域,能够解决不能除去被截留的气体等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

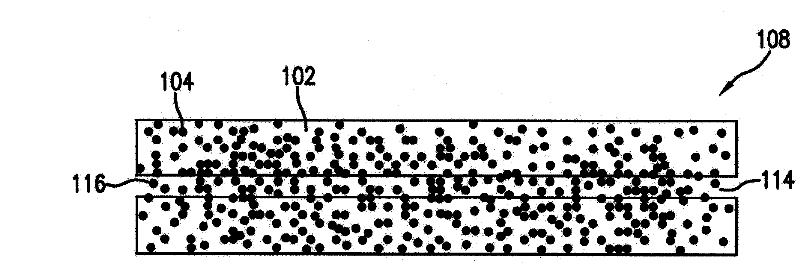

[0071] The following examples are provided to demonstrate the advantages of the disclosed embodiments of perforated prepregs. For example, it was observed that perforated prepregs 200, 202 significantly improved gas removal from perforated prepreg layups 300, 310 compared to prepregs without perforations, without edge venting, and produced low porosity composites. Furthermore, the examples show that the rate of removal of gases 302A, 302B, 302C from within and between layers of a perforated prepreg within a layup is greater than a comparable prepreg without perforations. These examples are discussed for illustrative purposes only and should not be construed as limiting the scope of the disclosed embodiments. Example 1 - Carbon Fiber / Epoxy Composite Fabricated from Partially Impregnated Prepreg Using Vacuum Bag Only (VBO) Conditions in Oven

[0072] Three carbon fiber / epoxy composites, Trials 1, 2 and 3, were fabricated from partially impregnated prepreg encapsulated in vacuu...

Embodiment 2

[0083] Example 2 - Carbon Fiber / Epoxy Composite Fabricated from Partially Impregnated Prepreg Using Autoclave Pressure and Vacuum

[0084] Three carbon fiber / epoxy composites, trials 4, 5 and 6, were fabricated from partially impregnated prepregs using vacuum and autoclave pressure. The edge ventilation and the presence or absence of perforations were varied to examine the effect of each on the porosity of the composite. It was observed that composites made from partially impregnated perforated prepregs without edge venting using autoclave pressure exhibit significantly greater lower porosity. The porosity levels of composites made from edge-vented perforated prepregs using autoclave pressure exhibited approximately the same porosity levels as comparable composites made from edge-vented non-perforated prepregs, and essentially Smaller than non-perforated prepreg without edge venting.

[0085] Trial 4 - Non-perforated prepreg with edge venting

[0086] The weight of fiber c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com