Method for automatically testing DCS (Digital Control System) control cabinet

A test method and control cabinet technology, applied in the fields of nuclear reactor monitoring, reactors, nuclear power generation, etc., can solve the problems of poor generality of test methods and inability to adapt to technological development, DCS can not achieve multi-point testing, etc., to achieve the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

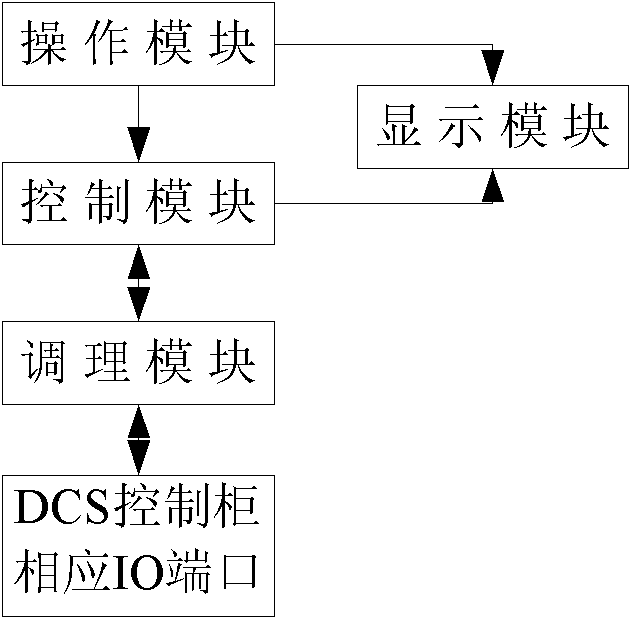

[0031] like figure 2 As shown, the test method of this method includes the following functional modules:

[0032] Display module: used to display various information of the operation module and control module;

[0033] The display module uses the display screen of the industrial computer to display the test selection input by the operator and the feedback results of the corresponding test, and at the same time display the control interface and selection interface of each test program. , process and equipment are clear at a glance.

[0034] Operation module: used to input various test commands to the control module;

[0035] Control module: After receiving the test command from the operation module, call the corresponding test program to execute and send the generated test signal to the conditioning module, and is responsible for receiving the feedback information from the conditioning module, and output the result on the display module.

[0036] The test program received a...

Embodiment 2

[0045] On the basis of Embodiment 1, a bias program is set on the conditioning module. The bias program belongs to the category of AO conditioning. It performs voltage compensation on the basis of the standard voltage test signal sent by the control module, and the compensated voltage is output after conditioning. Unconventional current and voltage test signals are used to perform over-limit tests on the DCS control cabinet and test the bearing capacity of the IO terminals. In this scheme, the range of voltage compensation is set to ±2V, and the unconventional current test signal output after conditioning is 0~ 24mA, voltage test signal is -2 ~ 12V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com