Modular steel containment vessel annular hanging beam and assembling method thereof

A steel containment and installation method technology, which is applied in the manufacture of reactors, nuclear power generation, climate sustainability, etc., can solve the problems of no reference to the assembly and installation information of containment ring hanging beams, high safety risks, and many high-altitude operations and other issues to achieve the effect of shortening the construction and installation period, reducing safety risks, and realizing workshop manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

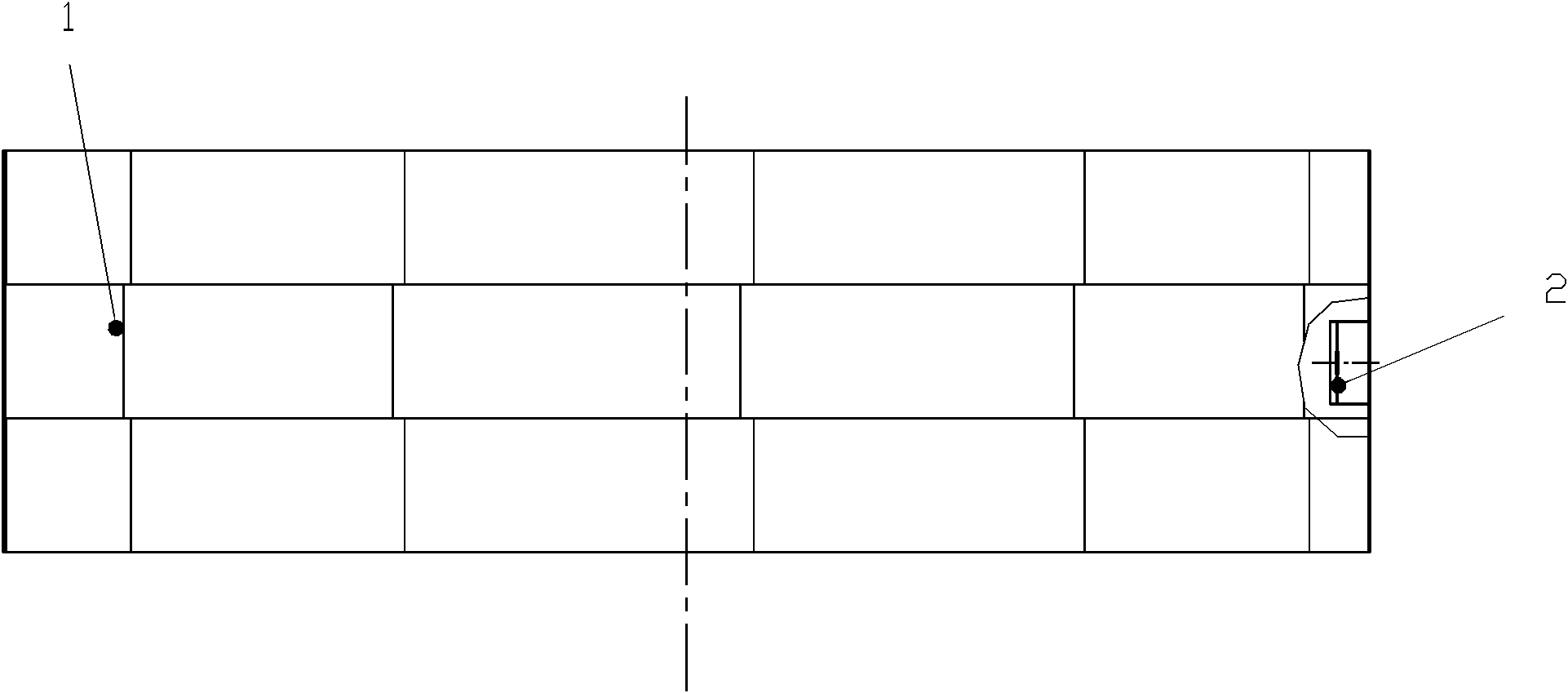

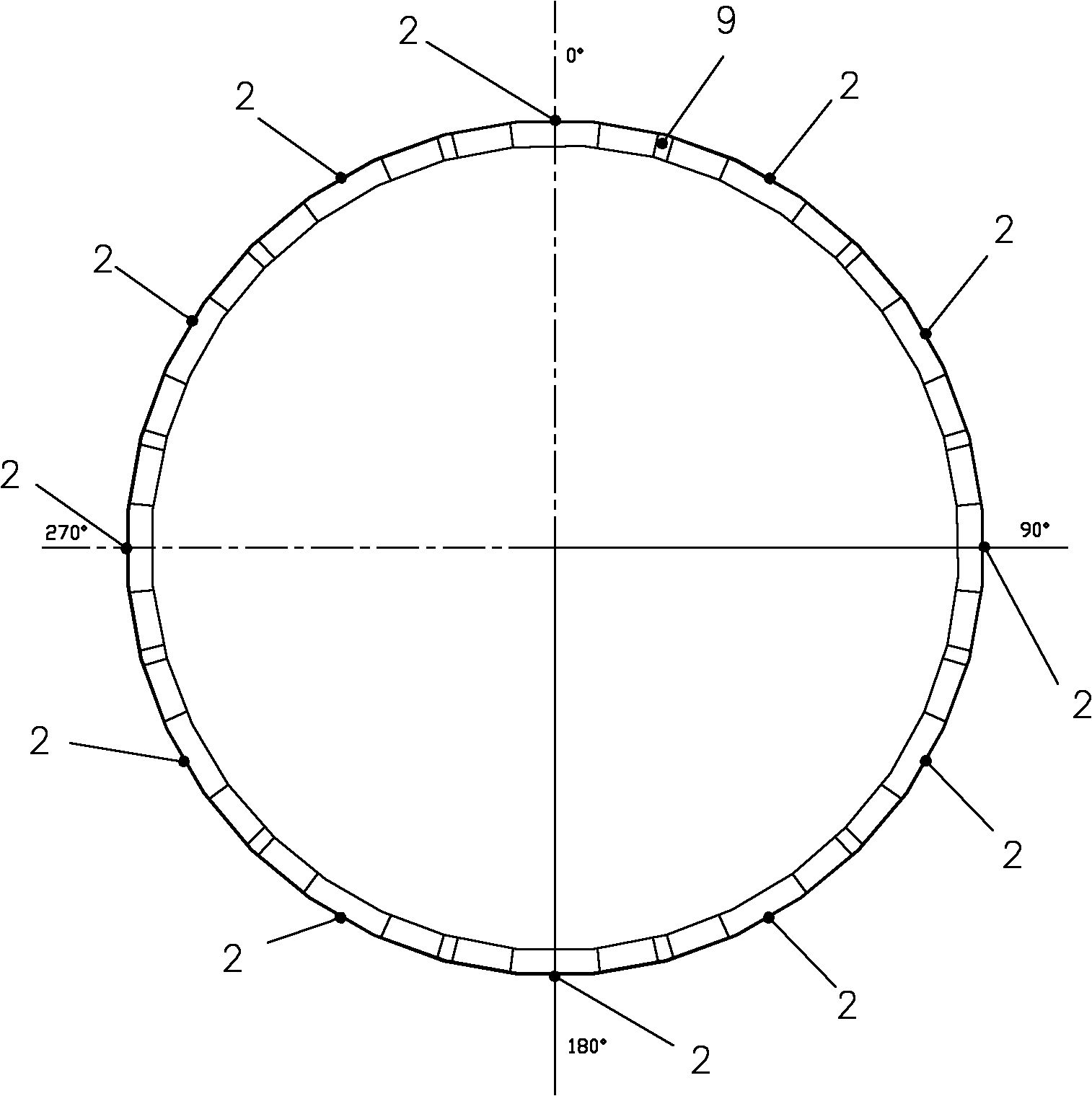

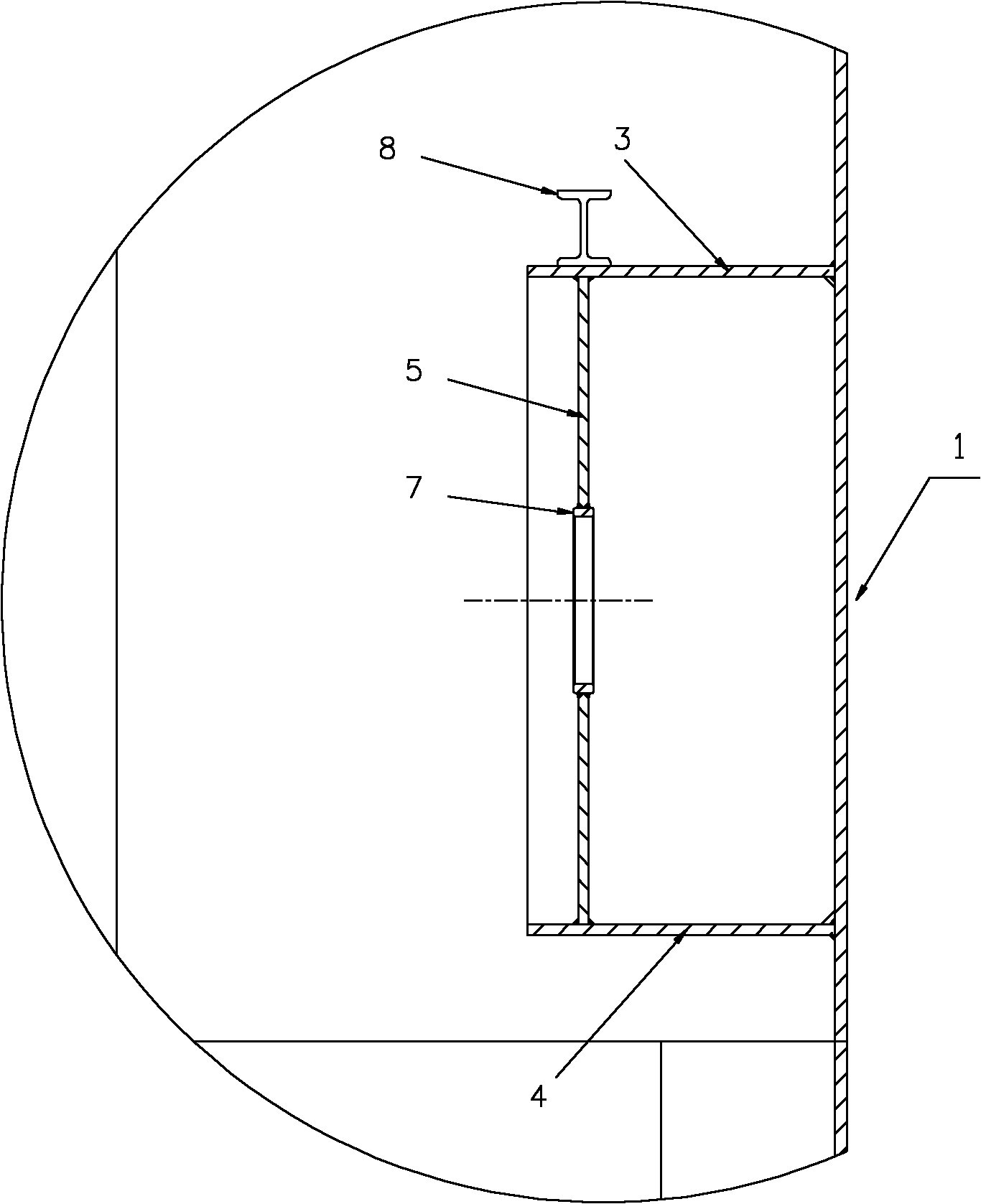

[0052] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Among them, it includes a plurality of containment arc plates 1, and the containment arc plates 1 are spliced to form a whole ring; on the inner wall of each containment arc plate 1, a plurality of ring hanging beam modules are arranged, thereby forming a ring hanging beam split 2. Each ring suspension beam module includes an upper ring plate 3 and a lower ring plate 4, and the rib plate 5 and the vertical plate 6 are connected between the upper ring plate 3 and the lower ring plate 4. The rib plate 5 is provided with an annular hole 7 . The upper ring plate 3 is provided with a track 8 .

[0053] The two adjacent ring suspension beam splits are connected by upper and lower connecting plates 9 .

[0054] Installation and assembly method of the present invention:

[0055] 1. Carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com