Method for matching optimal assembly poses of large-sized parts

A technology of optimal assembly and matching methods, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as unsatisfactory effects and economical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

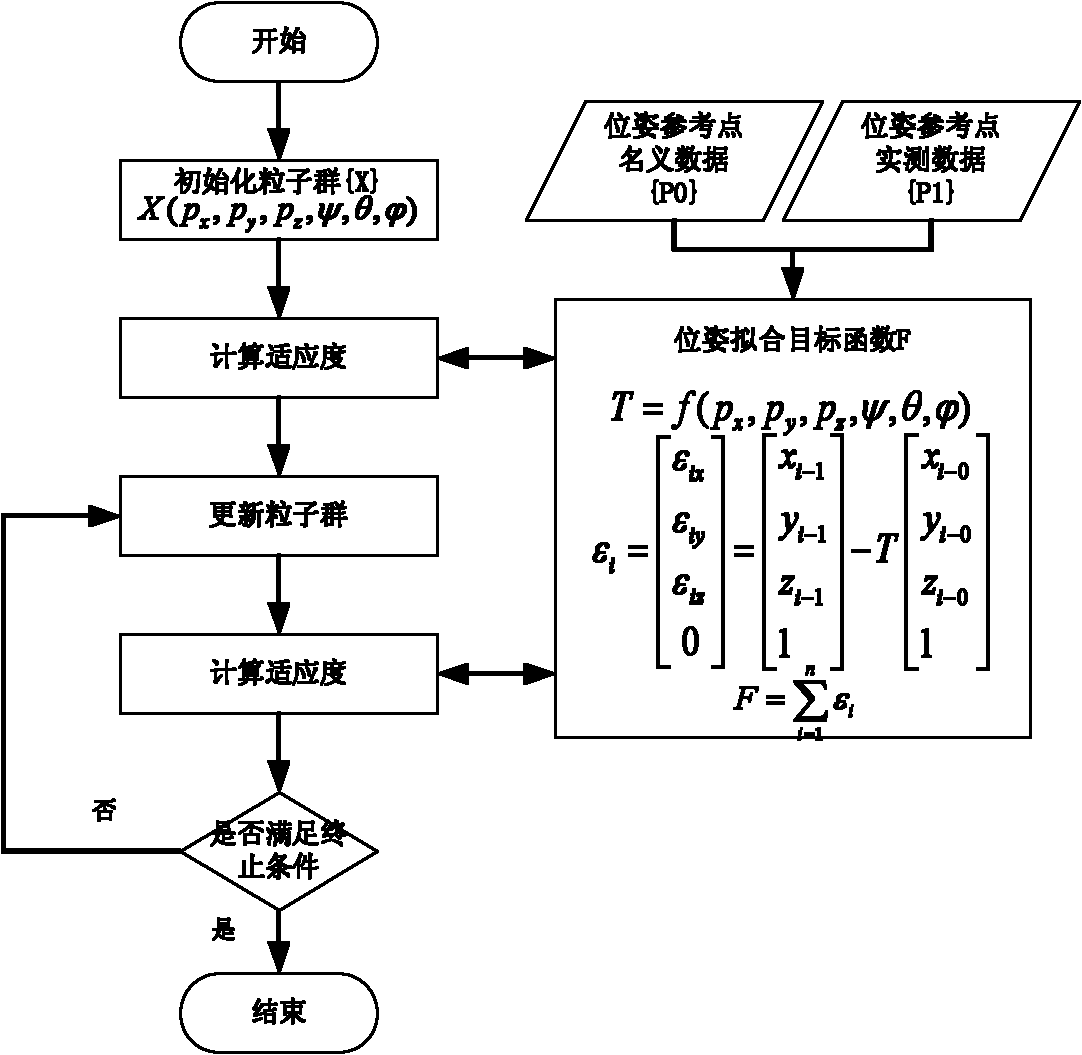

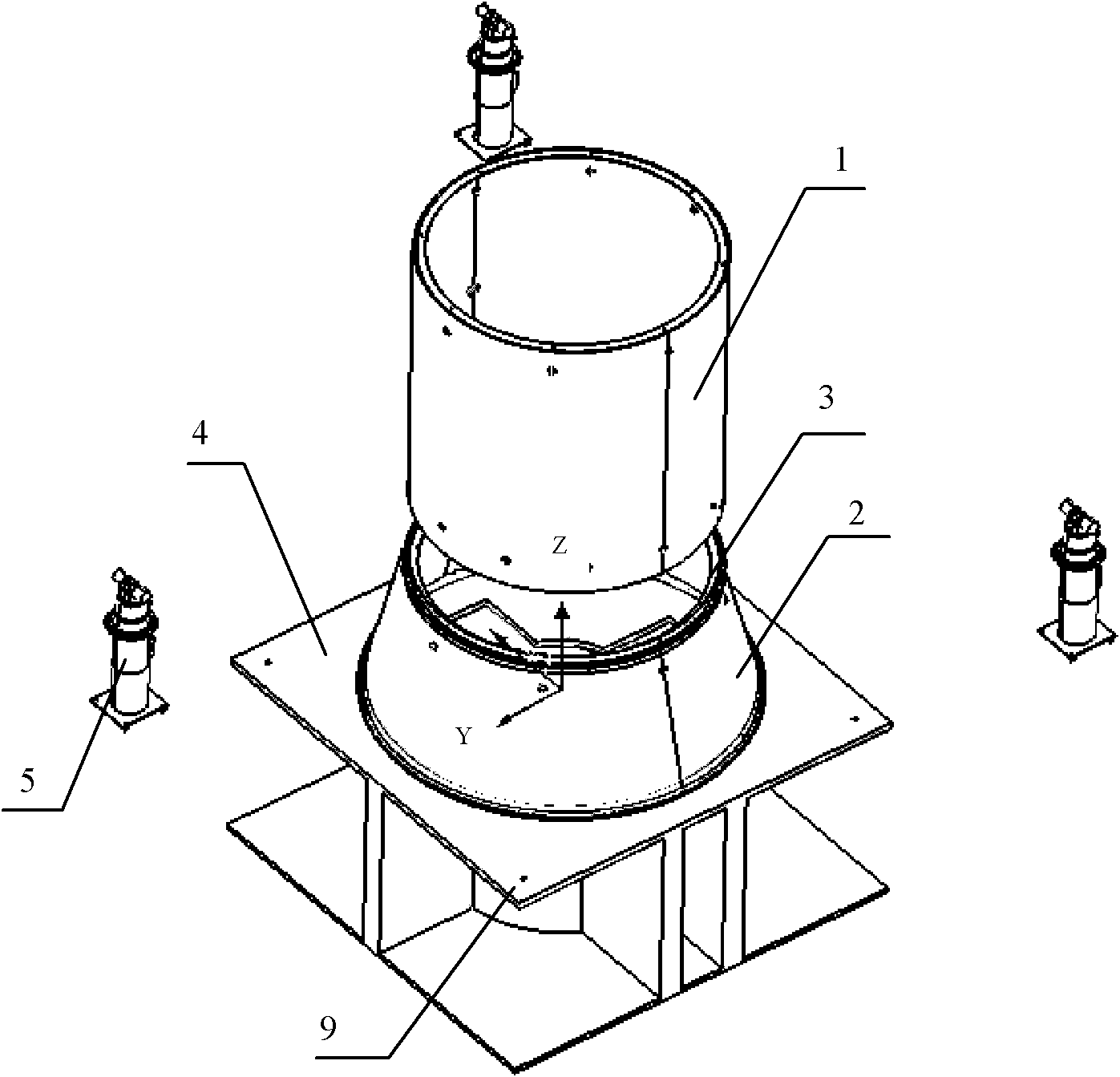

[0054] The method of optimal assembly pose matching in large-scale parts assembly, which includes two stages: current pose matching of parts and best target assembly pose matching of parts:

[0055] The current pose matching stage includes the following basic steps:

[0056] 1) Determine the spatial position of the fixed datum reference point in the assembly site;

[0057] 2) Fit the datum reference point into the datum assembly coordinate system, and unify it with the global coordinate system in the digital assembly model;

[0058] 3) Determining the spatial position of each position reference point on the movable assembly to be positioned;

[0059] 4) Comparing the nominal position of each position reference point in the digital assembly model, using the current pose matching algorithm to obtain six independent parameters of the current spatial pose of the assembly;

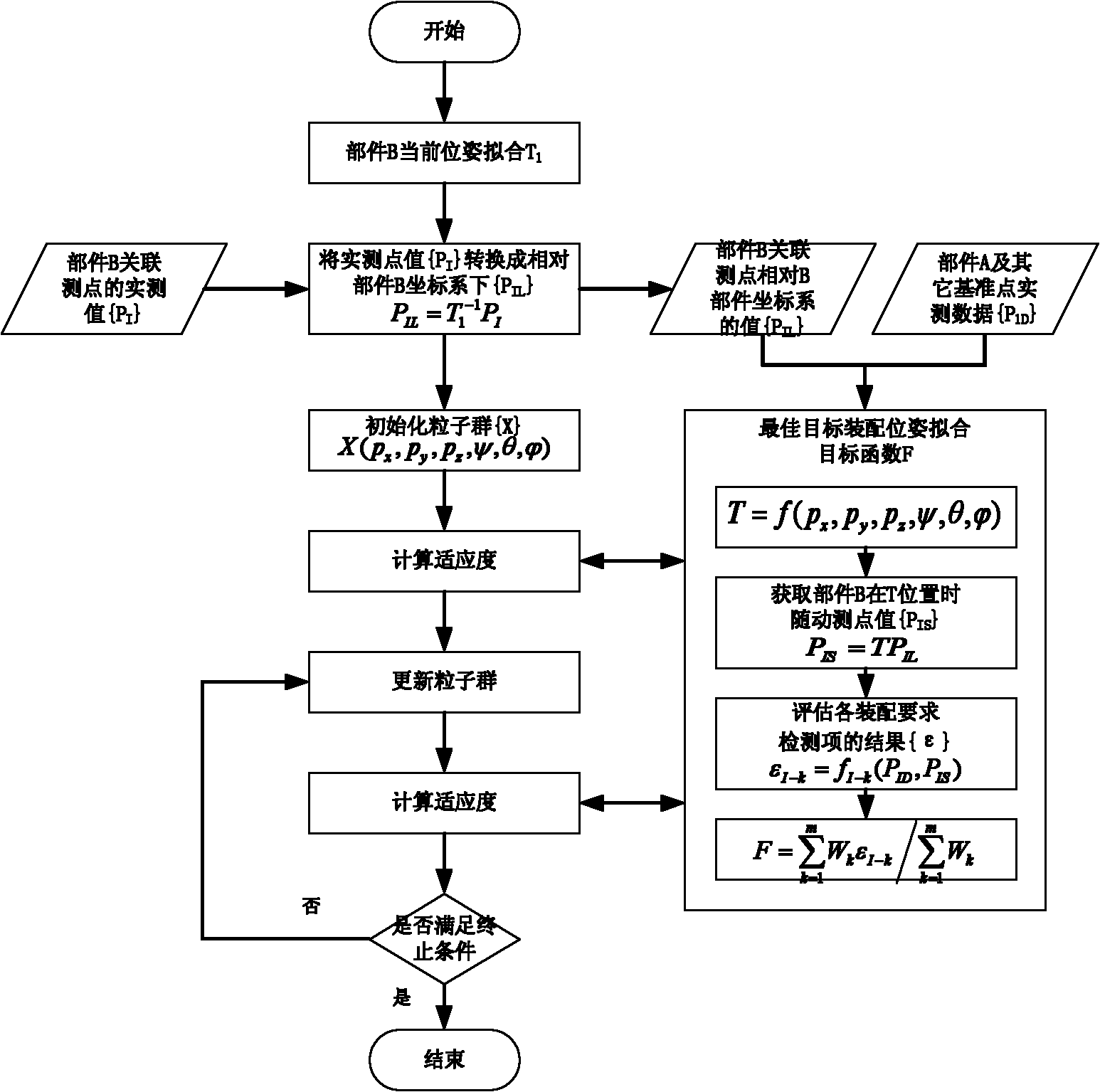

[0060] The optimal target assembly pose matching stage consists of the following basic steps:

[0061] 5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com