Flow control valve special for air spring with additional air chamber

A technology of flow control valve and additional air chamber, which is applied in the field of vehicle air suspension system, can solve the problems such as the correction of the accuracy degree of the inability to adjust the throttle hole, the loss of the function of the additional air chamber, and the loss of adjustment rigidity, so as to achieve precise adjustment and smooth flow. The effect of rapid change of flow area and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

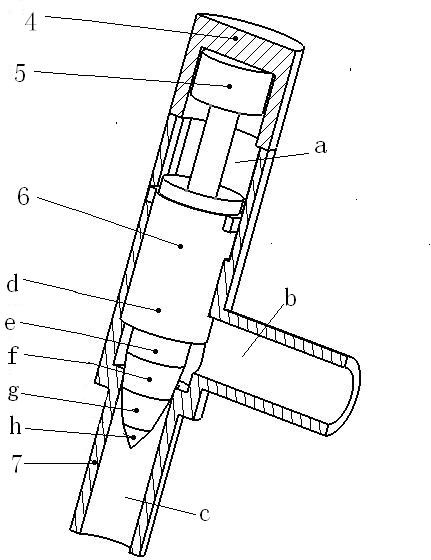

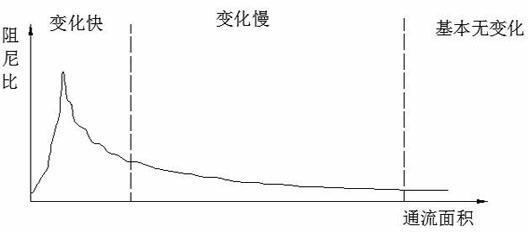

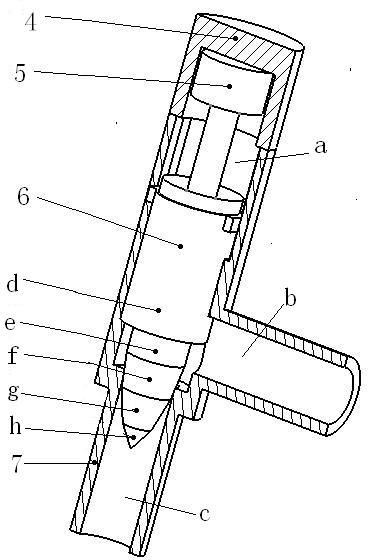

[0011] see figure 1 , the present invention includes a control valve tube body 7, the upper part of the control valve tube body 7 is the control chamber a, the lower part is the pipeline c connected to the additional air chamber, and the side part is another pipeline b connected to the main air chamber, the control chamber a It is coaxial with the pipeline c, and the diameter of the control chamber a is larger than that of the pipeline c, and the control chamber a communicates with the pipelines b and c. The inner diameter of the pipeline b should not be smaller than the inner diameter of the pipeline c, and should not be larger than the inner diameter of the control room a. An upper cover 4 is fixedly installed on the upper end of the control room a, and a stepping motor 5 is arranged in the upper cover 4, and the stepping motor 5 is coaxially connected with the control valve core 6 through an output shaft, and the stepping motor 5 is arranged on the control valve body 7 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com