High revolving speed fuel oil magnetic valve and method for measuring closing and starting points thereof

A solenoid valve and high-speed technology, applied in the field of solenoid valves, can solve the problems of poor dynamic performance, low robustness, and inconvenience of mass production of solenoid valves, and achieve reduced secondary fuel injection, precise fuel control, and low operating noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

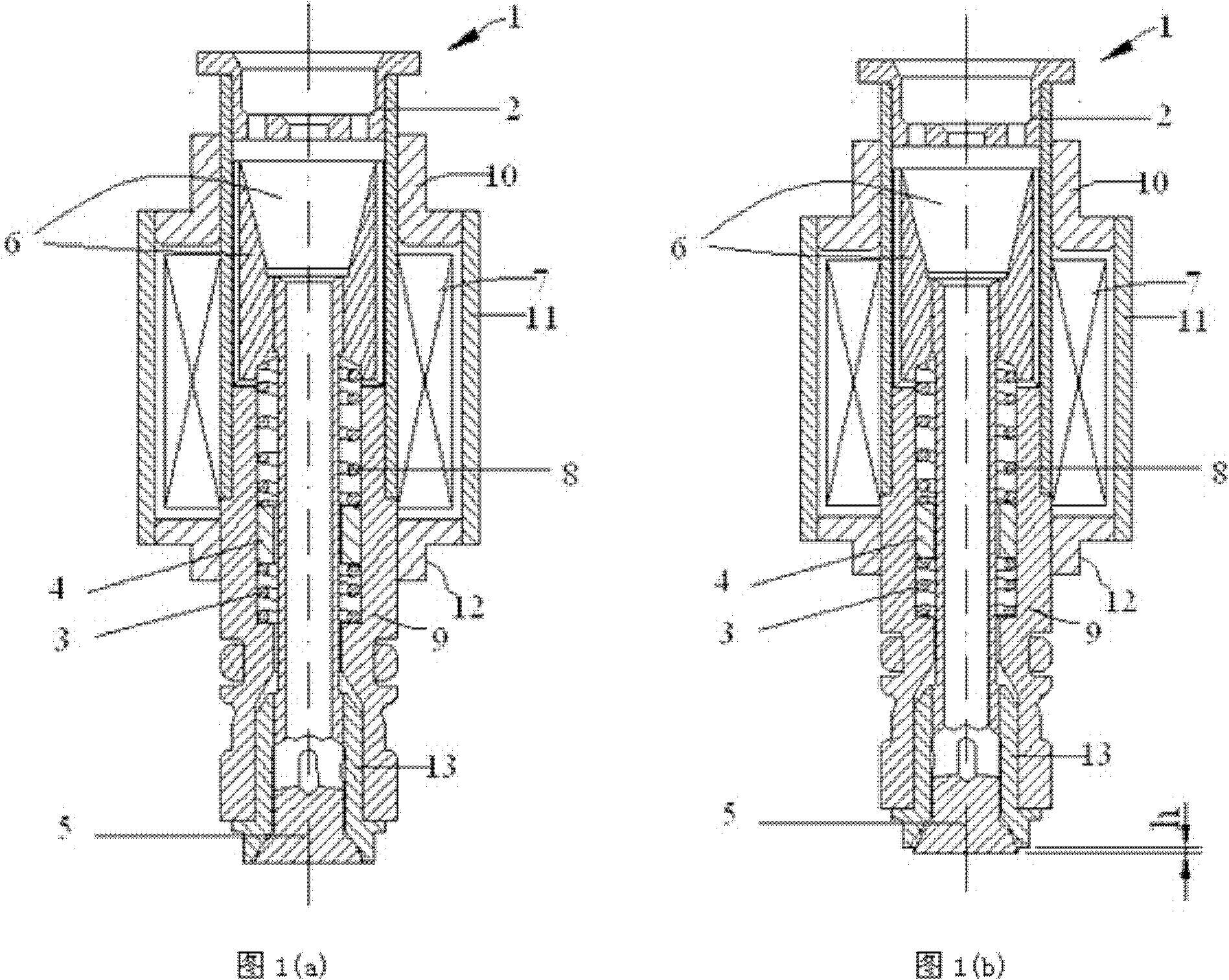

[0024] The accompanying drawings disclose non-restrictive structural schematic diagrams of preferred embodiments involved in the present invention, and the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as figure 1As shown, the high-speed fuel solenoid valve 1 of the present invention includes a valve body, and the two ends of the valve body are respectively equipped with a valve end cover 2 and a valve seat 13, and the valve end cover 2 is provided with an oil inlet, and the valve seat 13 Then open the oil outlet, the inner cavity of the valve body is equipped with a valve core 6, the valve core 6 is the armature, and the valve core 6 is arranged close to the valve end cover 2, and the inner cavity of the valve seat 13 is matched with the valve closing member. 5. In addition, an electromagnetic coil 7 is installed in the inner cavity of the valve, and the valve core 6 is supported on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com